DOING palm oil production process

DATE:2016-06-23 17:22/ Palm oil press/ Chat Online

Palm oil production process:

Alongside the development of large-scale fully mechanised palm oil mills and their installation in plantations supplying the international edible oil refining industry, small-scale village and artisanal processing has continued in Africa. Ventures range in throughput from a few hundred kilograms up to 8T FFB(fresh fruit bunch) per day and supply crude oil to the domestic market.

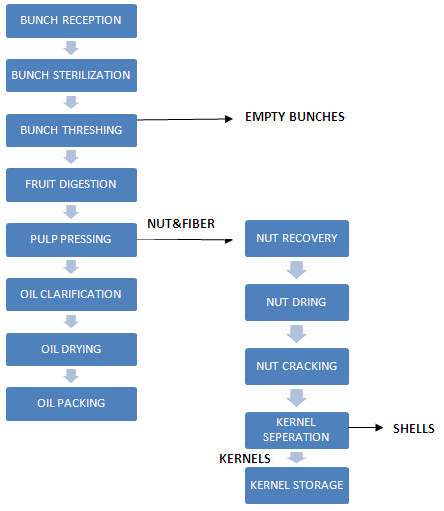

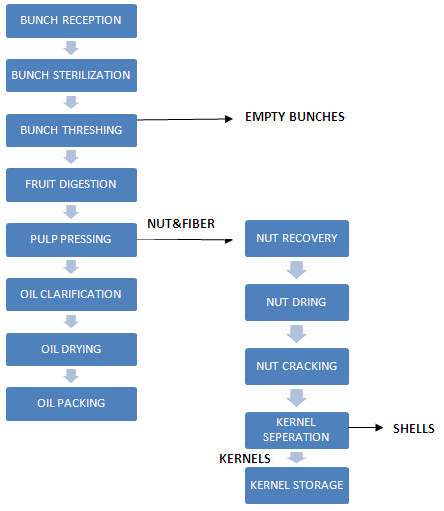

The general flow diagram of palm oil production process as follows:

Palm oil production process

Palm oil production process:

Step 1 BUNCH STERILIZATION: FFB (fresh fruit bunch) have to be sent to sterilize to avoid AV (acid value) rise by sterilize the fatty enzyme with high temperature. At the mean time, sterilizing section can also soften the fruits, which benefits the threshing section and reduces the damage to kernel.

Palm oil production process:

Step 2 BUNCH THRESHING: The purpose of threshing is to separate the palm fruit from the FFB by rotary drum thresher.

Palm oil production process:

Step 3 FRUIT DIGESTION: The purpose of digestion is to separate the pulp and kernel, soften the pulp with heat and to destroy the pulp cell structure.

Palm oil production process:

Step 4 PULP PRESSING: After sterilizing, threshing and crashing, palm pulp become soft and the cell structure is broken. In another word, we can easily get the oil with spiral oil press, which is also called CPO(crude palm oil).

Henan Doing Machinery , we have been concentrated on palm oil machine for 40years. If u need anything more about palm oil. Please contact us.

RELATED INFORMATION: