How to produce refined vegetable oil from palm kernel oil?

Every vegetable contains varying amounts of vegetable oil. This “crude vegetable oil” is the unrefined and unprocessed oil produced from vegetables – and how it is found in the natural vegetable oil state when it is first extracted from the vegetable, whether the vegetable oil comes from corn, soybeans, oil palm, jatropha, cottonseed, etc. To make the crude vegetable oil ready for use, it must undergo further processing and refining to take it from its crude form to a “refined vegetable oil” state.

Palm Kernel Oil is the main output of any Palm Kernel oil expelling process. Palm kernel oil consist mainly of glycerides and, like other oils in their crude form may consist of small and variable portions of non-glyceride components as well. ln order to render the oils to an edible form, some of these non-glycerides need to be either removed or reduced to an acceptable level.

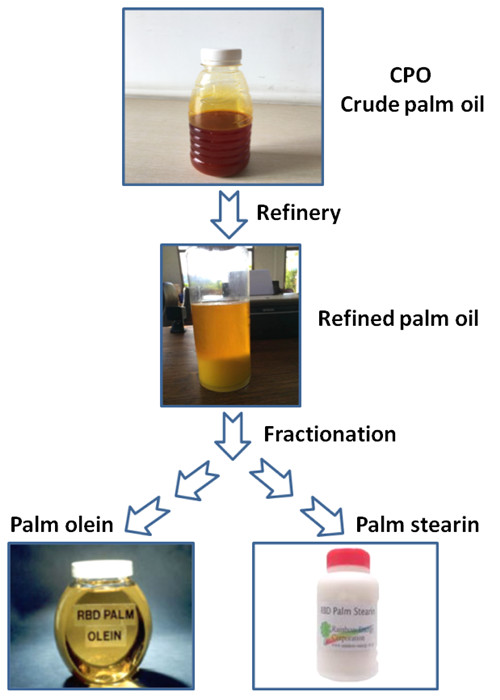

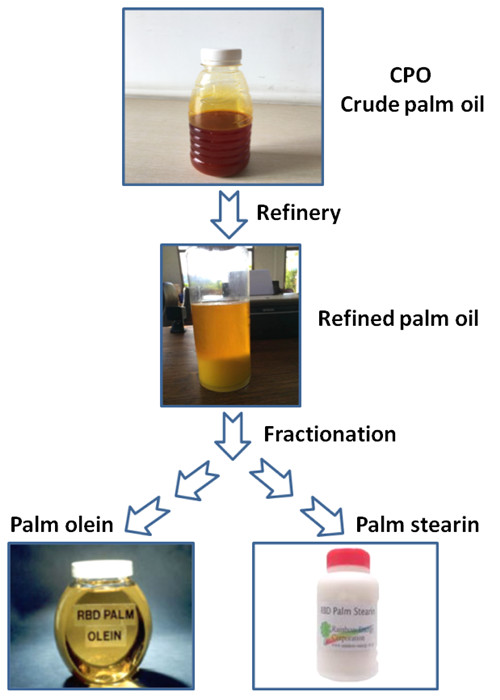

Palm kernel oil products

In Nigeria, Palm Kernel Oil is the major raw material for the production of edible vegetable oil. Ninety percent of what is called groundnut oil in our market today is in fact vegetable oil made from palm kernel oil (PKO). Original groundnut oil which is three times more costly than refined vegetable oil made from palm kernel oil cannot be afforded by ninety percent of Nigerian housewives.

Refining produces an edible oil with characteristics that consumers desire such as bland flavour and odour, clear appearance, light colour, stability to oxidation and suitability for frying. Two main refining routes are alkaline refining and physical refining (steam stripping, distillative neutralisation) which are used for removing the free fatty acids.

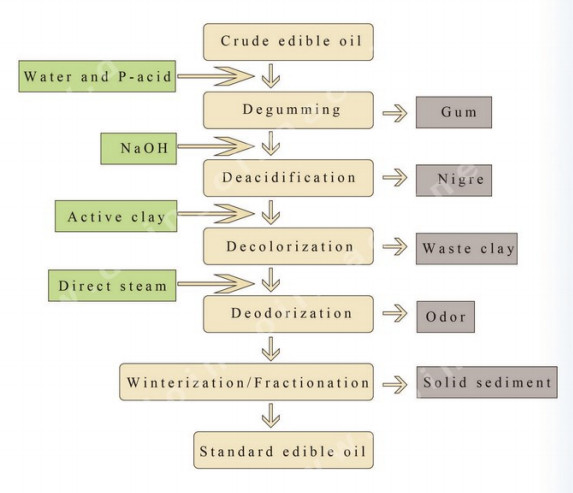

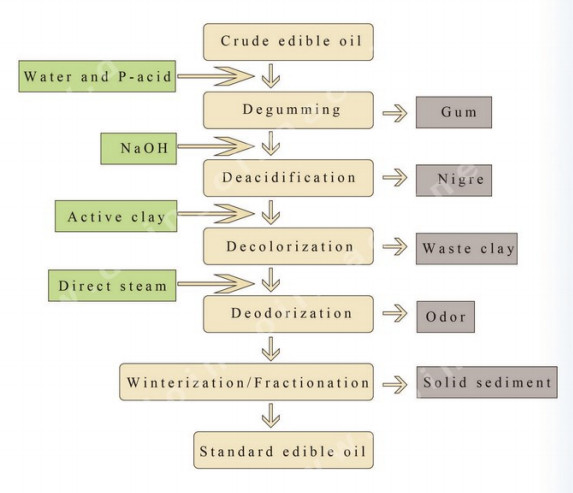

The palm kernel oil refining process usually comprises the following steps:

Palm kernel oil refining process

Step 1.Palm kernel oil degumming section

Degumming with water to remove the easily hydratable phospholipids and metals.

Step 2.Palm kernel oil deacidification section

Addition of a small amount of phosphoric or citric acid to convert the remaining non-hydralable phospholipids (Ca, Mg salts) into hydratable phospholipids.

Step 3.Palm kernel oil neutralizing section

Neutralising of the free fatty acids with a slight excess of sodium hydroxide solution, followed by the washing out of soaps and hydrated phospholipids.

Step 4.Palm kernel oil bleaching section

Bleaching with natural or acid-activated clay minerals to adsorb colouring components and to decompose hydroperoxides.

Step 5.Palm kernel oil deodorising section

Deodorising to remove volatile components, mainly aldehydes and ketones, with low threshold values for detection by taste or smell. Deodorisation is essentially a steam distillation process carried out at low pressures (2-6 mbar) and elevated temperatures (180-220°C).

The market for vegetable oil is national. With a population of over 165 million people and an estimated national population growth rate of 5.7% per annum ,an average economic growth rate of 3.5% per annum in the past five {5} years, Nigeria has a large market for edible oil.

The demand is high but local supply low hence the need for importation in the past. Industry data suggest that Nigerian consumers use more than one million {1,000,000} tones of vegetable oil annually. After know this, if you are interested in palm kernel oil refinery plant and want to know more information about palm kernel oil refinery process, please feel free to contact us!

Palm Kernel Oil is the main output of any Palm Kernel oil expelling process. Palm kernel oil consist mainly of glycerides and, like other oils in their crude form may consist of small and variable portions of non-glyceride components as well. ln order to render the oils to an edible form, some of these non-glycerides need to be either removed or reduced to an acceptable level.

Palm kernel oil products

In Nigeria, Palm Kernel Oil is the major raw material for the production of edible vegetable oil. Ninety percent of what is called groundnut oil in our market today is in fact vegetable oil made from palm kernel oil (PKO). Original groundnut oil which is three times more costly than refined vegetable oil made from palm kernel oil cannot be afforded by ninety percent of Nigerian housewives.

Refining produces an edible oil with characteristics that consumers desire such as bland flavour and odour, clear appearance, light colour, stability to oxidation and suitability for frying. Two main refining routes are alkaline refining and physical refining (steam stripping, distillative neutralisation) which are used for removing the free fatty acids.

The palm kernel oil refining process usually comprises the following steps:

Palm kernel oil refining process

Step 1.Palm kernel oil degumming section

Degumming with water to remove the easily hydratable phospholipids and metals.

Step 2.Palm kernel oil deacidification section

Addition of a small amount of phosphoric or citric acid to convert the remaining non-hydralable phospholipids (Ca, Mg salts) into hydratable phospholipids.

Step 3.Palm kernel oil neutralizing section

Neutralising of the free fatty acids with a slight excess of sodium hydroxide solution, followed by the washing out of soaps and hydrated phospholipids.

Step 4.Palm kernel oil bleaching section

Bleaching with natural or acid-activated clay minerals to adsorb colouring components and to decompose hydroperoxides.

Step 5.Palm kernel oil deodorising section

Deodorising to remove volatile components, mainly aldehydes and ketones, with low threshold values for detection by taste or smell. Deodorisation is essentially a steam distillation process carried out at low pressures (2-6 mbar) and elevated temperatures (180-220°C).

The market for vegetable oil is national. With a population of over 165 million people and an estimated national population growth rate of 5.7% per annum ,an average economic growth rate of 3.5% per annum in the past five {5} years, Nigeria has a large market for edible oil.

The demand is high but local supply low hence the need for importation in the past. Industry data suggest that Nigerian consumers use more than one million {1,000,000} tones of vegetable oil annually. After know this, if you are interested in palm kernel oil refinery plant and want to know more information about palm kernel oil refinery process, please feel free to contact us!

Leave A Message

If you want to know more information about How to produce refined vegetable oil from palm kernel oil? . pls kindly leave your phone number, We will back to you ASAP once we got your message.

contact us

Palm Oil Extraction FAQ

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

What is Fractionated Palm Oil Used For?

What is Fractionated Palm Oil Used For?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines

-

What Are the Benefits of Using a Professional Vegetable Oil Refining Machine

What Are the Benefits of Using a Professional Vegetable Oil Refining Machine

Products