2tpd palm kernel oil refining machine

Factory direct sale contact number

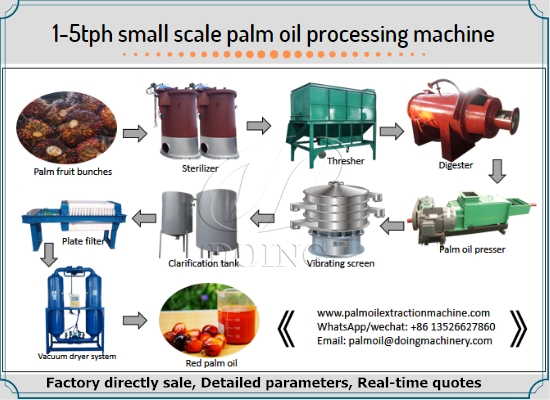

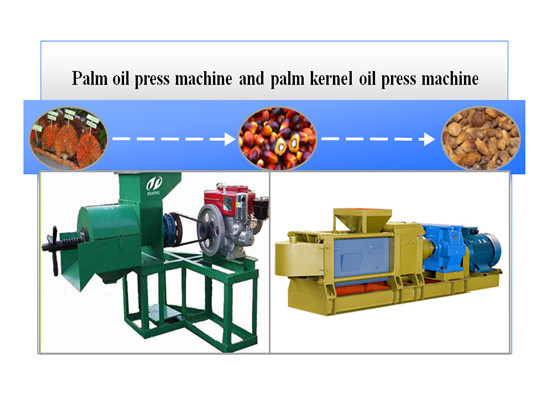

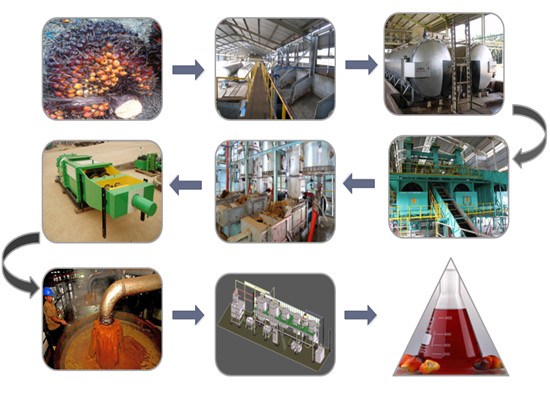

Cooking oil refinery plant is used to process crude oil . The 2tpd palm kernel oil refining machine is used for removing the impurities of palm kernel oil, such as fatty acid, phosphatide, pigment. After the process of palm kernel oil refining machine, the refined oil reaches the edible oil standard. 2tpd palm kernel oil refining machine is suitable for refining various crude oil, vegetable oil, such as sunflower seed oil, tea seed oil, coconut oil, olive oil, palm oil, peanut oil, soybean oil, corn oil, groundnut oil and so on.

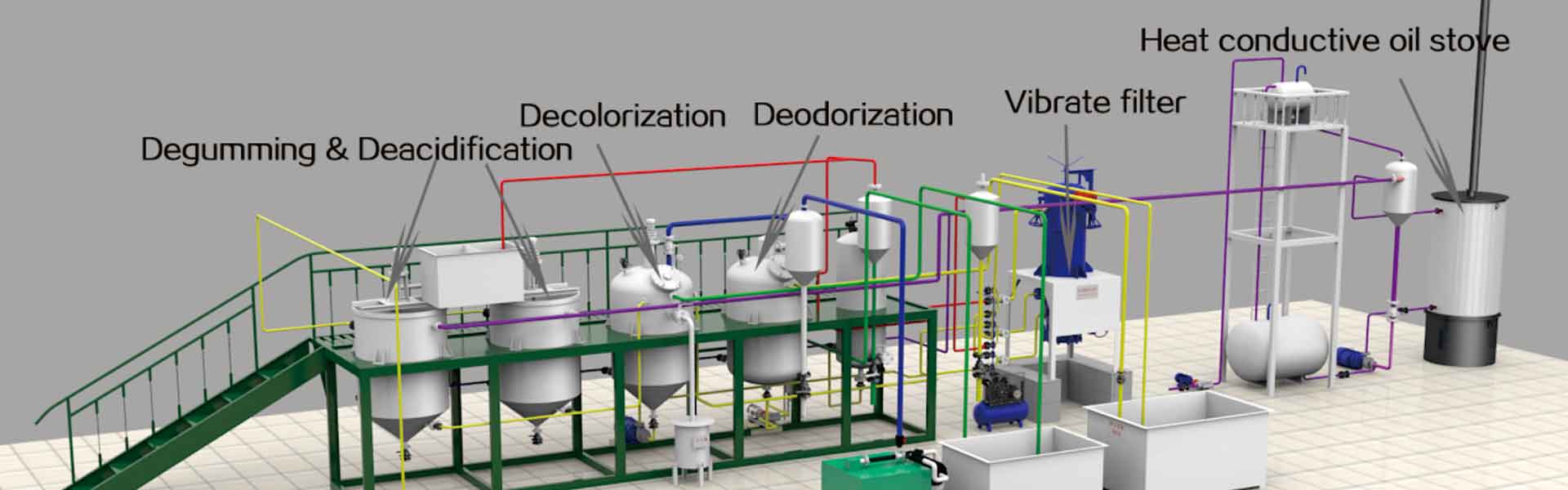

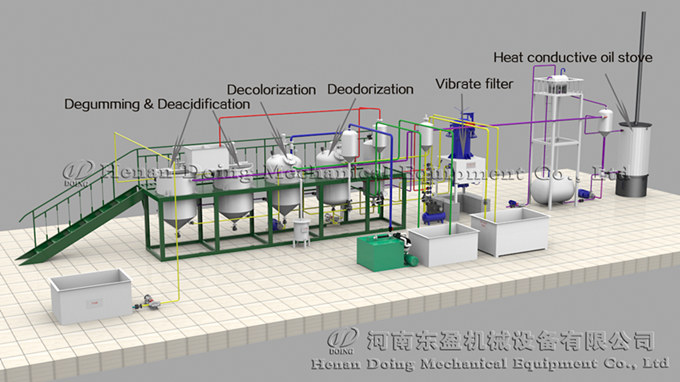

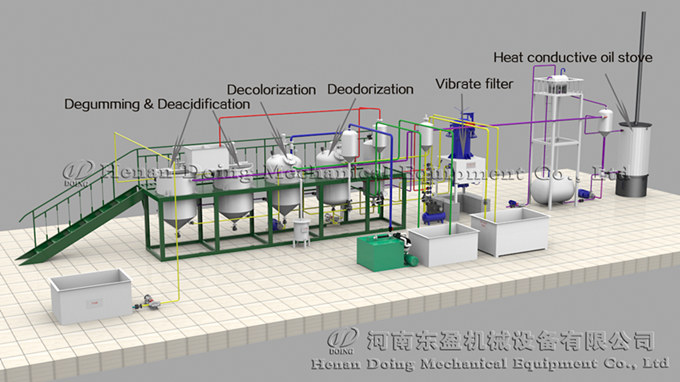

3D animation of palm kernel oil refining machine

Advantages of 2tpd palm kernel oil refining machine:

1. Customized capacity. We customize edible oil refinery plant as per your requirement for the capacity.

2. Flexible usage. The edible oil refinery plant can work independently or together with whole edible oil production line.

3. Excellent after-sales service. We provide two engineers after your receipt of equipments for on site installation, debugging and training.

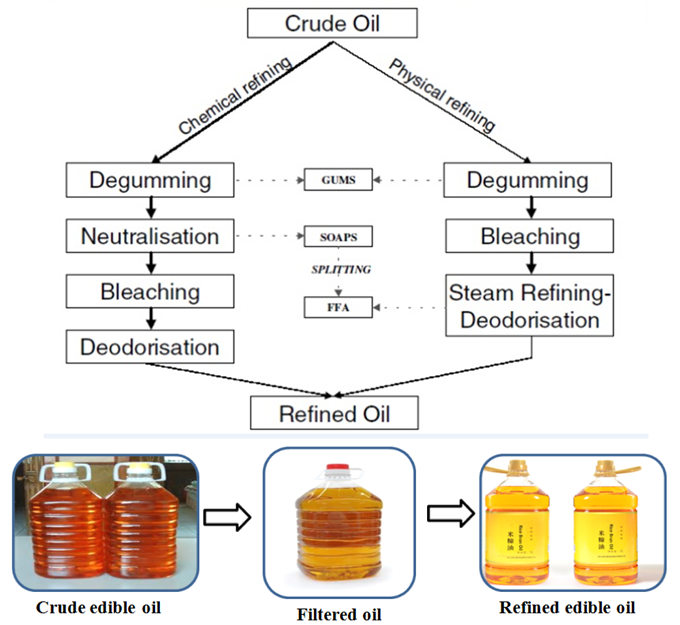

Palm kernel oil refining process

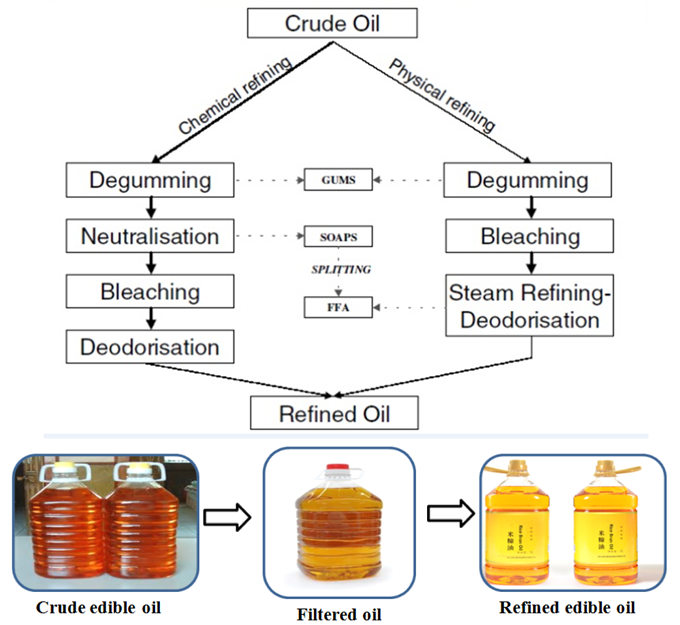

Main process of 2tpd palm kernel oil refining machine:

(1) Degumming ---- to remove gum and impurities from crude oil

(2) Deacidification---using alkali to neutralize acid inside crude oil

(3) Decoloration--- using clay to bleach crude oil

(4) Deodorization-- using deodorizing tower to remove odor from crude oil , then will get refined peanut oil

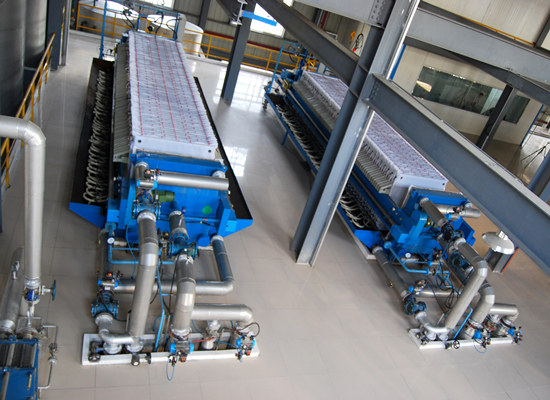

Palm kernel oil refining machine we have installed

Technical parameters of 2tpd palm kernel oil refining machine:

In general, there're 3 types of palm kernel oil refinery workshop, batch, semi-continuous, and continuous refinery workshop.

We have been specialized in palm kernel oil refining machine for decades and our engineer can help you design and install workshop according to your requirements. If you're interested in 2tpd palm kernel oil refining machine, please feel free to contact us.

3D animation of palm kernel oil refining machine

Advantages of 2tpd palm kernel oil refining machine:

1. Customized capacity. We customize edible oil refinery plant as per your requirement for the capacity.

2. Flexible usage. The edible oil refinery plant can work independently or together with whole edible oil production line.

3. Excellent after-sales service. We provide two engineers after your receipt of equipments for on site installation, debugging and training.

Palm kernel oil refining process

(1) Degumming ---- to remove gum and impurities from crude oil

(2) Deacidification---using alkali to neutralize acid inside crude oil

(3) Decoloration--- using clay to bleach crude oil

(4) Deodorization-- using deodorizing tower to remove odor from crude oil , then will get refined peanut oil

Palm kernel oil refining machine we have installed

Technical parameters of 2tpd palm kernel oil refining machine:

| Main economic technical parameters | |

| Steam consumption | 450KG/T oil |

| Electric consumption | 28Kwh/T oil |

| Phosphoric acid | 2~3 kg/T oil |

| Circulating water cooling water yield | 150m³/H |

| Bleaching earth consumption | 5~50Kg/T oil |

| Waste bleaching earth oil content | <35% |

| Deodorization loss consumption | ≤0.5% |

In general, there're 3 types of palm kernel oil refinery workshop, batch, semi-continuous, and continuous refinery workshop.

We have been specialized in palm kernel oil refining machine for decades and our engineer can help you design and install workshop according to your requirements. If you're interested in 2tpd palm kernel oil refining machine, please feel free to contact us.

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

Palm kernel oil refinery

Products

palm oil mill plant projects

Palm Oil Extraction FAQ

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines

recommend products