What Is the Clarification Station in a Large Palm Oil Mill?

In large palm oil mills, the pressed oil-water-fiber mixture is not qualified as direct-use crude palm oil. As the core section of a large palm oil mill, the clarification station converts this mixture into pure, stable crude palm oil that meets commercial standards, whose process efficiency and operational stability directly dictate the final product quality, oil yield and production efficiency.

Why Clarification Is Necessary?

Freshly pressed crude palm oil contains significant impurities, typically consisting of approximately 60% oil, 24% water and 16% solid contaminants (e.g., mesocarp fibers, sands). Without effective separation, high moisture and impurity content will accelerate oil rancidity and lead to substantial product devaluation.

Main Process Flow and Equipment

The clarification station of a large palm oil mill is mainly divided into three stages: primary impurity removal, core clarification and separation, and sludge oil recovery and treatment.

1. Primary Impurity Removal Stage

The pressed palm oil slurry is first pumped into a sand trap tank, where gravity sedimentation is used to preliminarily separate heavy impurities such as sand particles. Subsequently, the oil mixture is fed into a vibrating screen, which effectively filters out most coarse fibers and solid particles. The oil-bearing coarse residues trapped on the screen are recycled for reprocessing to boost the overall oil yield.

Vibrating screen

Vibrating screen

2. Core Clarification and Separation Stage

After primary impurity removal, the crude palm oil is heated and stabilized in a crude oil tank, then pumped into a vertical clarification tank—the core separation equipment of this stage. Equipped with steam coils for temperature control, the vertical clarification tank achieves efficient gravity sedimentation and stratification by leveraging the density differences among oil, water, and residue phases.

1) Upper Layer: Pure Oil

Pure palm oil floats to the top and is skimmed off and transferred to the pure oil tank.

2) Middle Layer: Sludge

Sludge and emulsions formed by water, fine solids, and residual oil are sent to the next stage for treatment.

3) Bottom Layer: Heavy Residues

The densest components such as fibers and sediments settle at the conical bottom and are discharged.

Vertical clarification tank

Vertical clarification tank

The pure oil output from the vertical clarification tank is then fed into a vacuum dryer, where residual moisture is removed under vacuum and heating conditions. Once it meets safe storage standards, the oil is pumped to the finished crude palm oil storage tank.

3. Sludge Recovery and Treatment Stage

To maximize oil recovery, the sludge from the middle layer undergoes a closed-loop recovery process.

1) Pretreatment

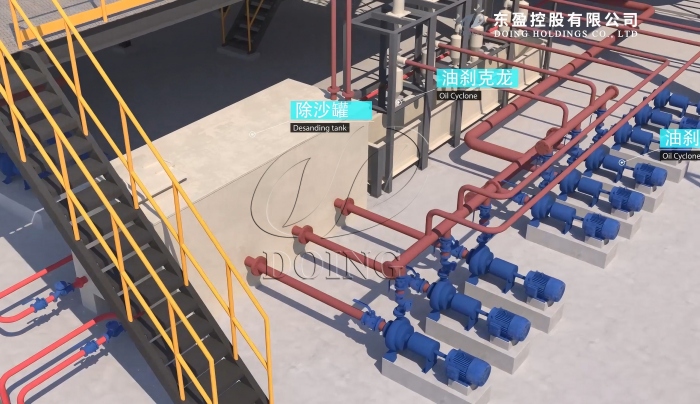

The sludge passes through a primary oil cyclone (with hot water added) and a desanding tank successively, undergoing cyclonic separation and static sedimentation to remove most sediments.

Oil cyclone and desanding tank

Oil cyclone and desanding tank

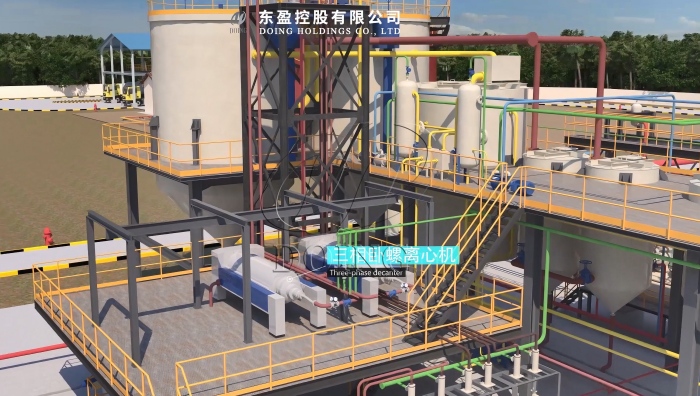

2) Core Separation

The pretreated mixture is fed into a three-phase decanter centrifuge, where it is completely separated into three phases (pure oil, wastewater, and sediments) under high centrifugal force.

Three-phase decanter

Three-phase decanter

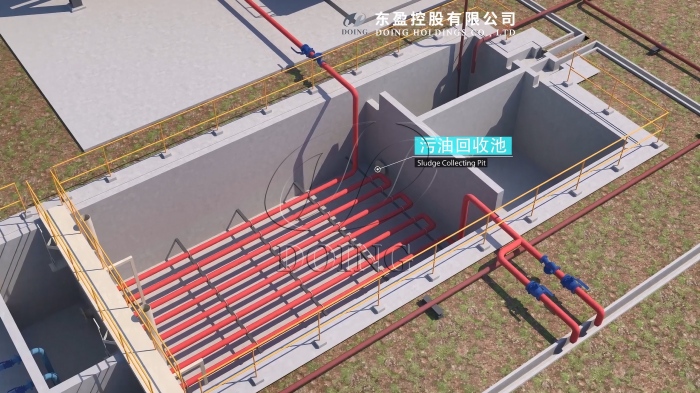

3) Closed-Loop Recovery

The separated purified palm oil is stored following simple filtration and dehydration. The sediments are diluted with water and settled to extract residual oil again. This process significantly improves the overall oil yield of the large-scale palm oil mill.

Sludge collecting pit

Sludge collecting pit

While producing crude palm oil, the clarification station also implements standardized management of all by-products:

1) Wastewater: Conveyed to the sewage treatment system and discharged or reused after meeting discharge standards.

2) Solid Residues: Combustible solids such as empty fruit bunches, fibers are used as boiler fuel to achieve energy recycling.

In conclusion, the process level of the clarification station in a large palm oil mill is directly related to the quality of your palm oil and production efficiency. If you wish to conduct an efficiency evaluation of your existing clarification process or explore technical upgrading solutions, please feel free to contact Henan Glory. Our professional team is ready to provide you with detailed consultations and customized support.

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines