Horizontal sterilizer, vertical sterilizer and tilting sterilizer

Factory direct sale contact number

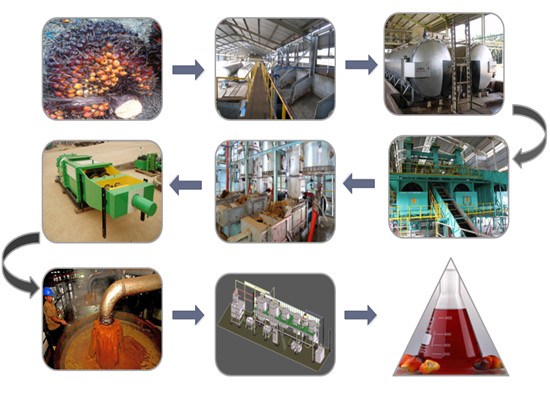

This palm fruit sterilization step in the palm oil extraction process is crucial to the final oil quality as well as the strippability of fruits. Sterilization inactivates the lipases in the fruits and prevents buildup of free fatty acids (FFA). In addition, steam sterilization of the FFBs facilitates fruits being stripped from the bunches. It also softens the fruit mesocarp for digestion and release of oil, and conditions nuts to minimize kernel breakage.

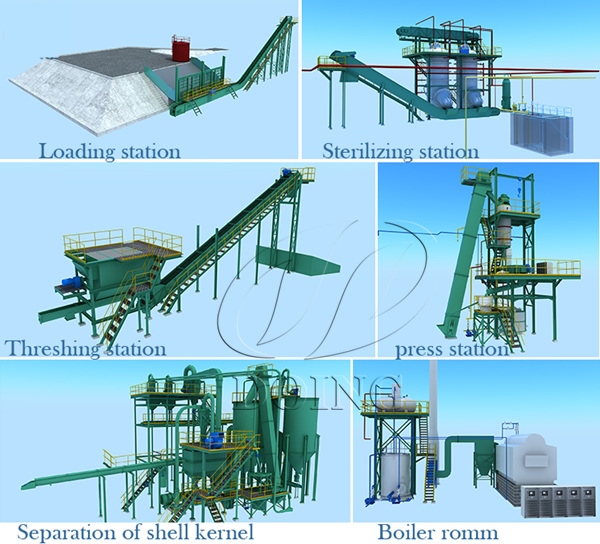

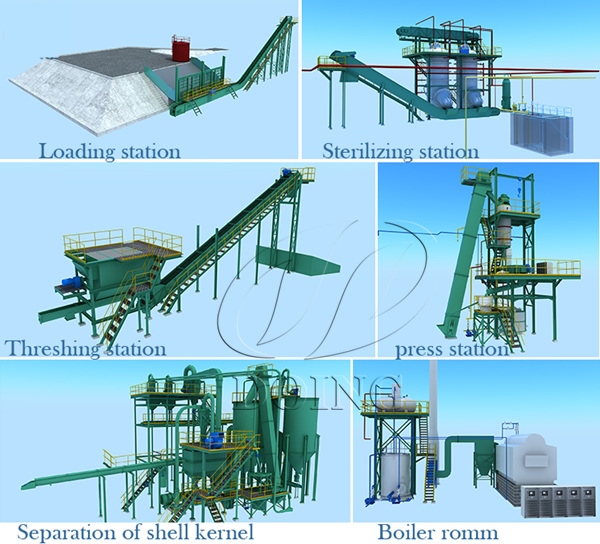

Main stations in palm oil mill plant

In recent years, new technology on sterilization saw the introduction of continuous sterilizers. Continuous sterilizer showed improved fruit strippability, even with usage of low-pressure steam or atmospheric steam. The new system consists of conveyor belts taking crushed FFBs into the continuous sterilizer, where the fruits are sterilized and subsequently discharged. This reduces much of the machinery associated with conventional sterilizers. In addition, there are cost savings in terms of manpower requirements, and maintenance.

The following discussion on the different types of sterilizer:

Horizontal Sterilizer

The horizontal sterilizer is the most commonly used sterilizer in palm oil mills. When disposed in a horizontal position, the cylindrical vessel sterilizer has fairly good disposition because the oil palm fresh fruit bunches placed in cages with a low stacking height are more uniformly spread out in this position across the length of the elongated vessel, as opposed to a vertical sterilizer. Thus, when pressurized steam is injected into the interior of the horizontally positioned cylindrical vessel, the steam can reach out to different directions and corners of the contents within the cages thereby helping treatment of the fruit bunches. Due to the low stacking height of the fruit bunches in the cages, condensate drains out freely from the fruit bunch stack facilitating heat penetration. The low stacking height also limits fruit bunch compression that facilitates low oil loss from the fruits during sterilisation.

Horizontal sterilizer in our customer's factory

Vertical Sterilizer

Vertical sterilizers are available in several variations where fresh fruit bunches are placed directly into a tall vertical vessel without steel cages. The vertical sterilizer is considered for use in palm oil mills where space saving is important. Vertical sterilizers are much cleaner and easier to operate than conventional sterilizers.

Vertical sterilizers

Vertical sterilizers with big capacity

Tilting sterilizer

Another type of sterilizer technology, the Tilting sterilizer eliminates much of the machinery associated with conventional sterilizers. The technology is the latest design that offers improved milling efficiency, and reduced labour and maintenance cost.

Tilting sterilizer used in palm oil mill

Main stations in palm oil mill plant

The following discussion on the different types of sterilizer:

Horizontal Sterilizer

The horizontal sterilizer is the most commonly used sterilizer in palm oil mills. When disposed in a horizontal position, the cylindrical vessel sterilizer has fairly good disposition because the oil palm fresh fruit bunches placed in cages with a low stacking height are more uniformly spread out in this position across the length of the elongated vessel, as opposed to a vertical sterilizer. Thus, when pressurized steam is injected into the interior of the horizontally positioned cylindrical vessel, the steam can reach out to different directions and corners of the contents within the cages thereby helping treatment of the fruit bunches. Due to the low stacking height of the fruit bunches in the cages, condensate drains out freely from the fruit bunch stack facilitating heat penetration. The low stacking height also limits fruit bunch compression that facilitates low oil loss from the fruits during sterilisation.

Horizontal sterilizer in our customer's factory

Vertical Sterilizer

Vertical sterilizers are available in several variations where fresh fruit bunches are placed directly into a tall vertical vessel without steel cages. The vertical sterilizer is considered for use in palm oil mills where space saving is important. Vertical sterilizers are much cleaner and easier to operate than conventional sterilizers.

Vertical sterilizers

Vertical sterilizers with big capacity

Tilting sterilizer

Another type of sterilizer technology, the Tilting sterilizer eliminates much of the machinery associated with conventional sterilizers. The technology is the latest design that offers improved milling efficiency, and reduced labour and maintenance cost.

Tilting sterilizer used in palm oil mill

Leave A Message

If you want to know more information about Horizontal sterilizer, vertical sterilizer and tilting sterilizer . pls kindly leave your phone number, We will back to you ASAP once we got your message.

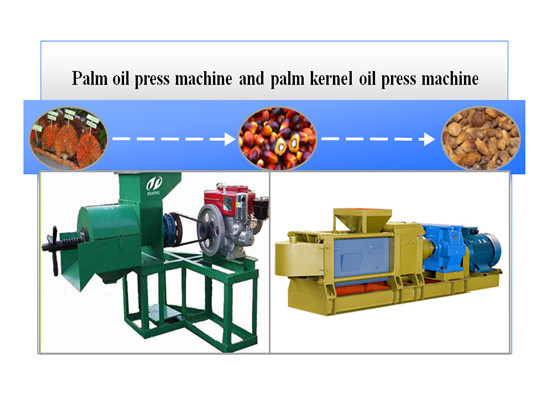

Palm oil press

Products

palm oil mill plant projects

Palm Oil Extraction FAQ

-

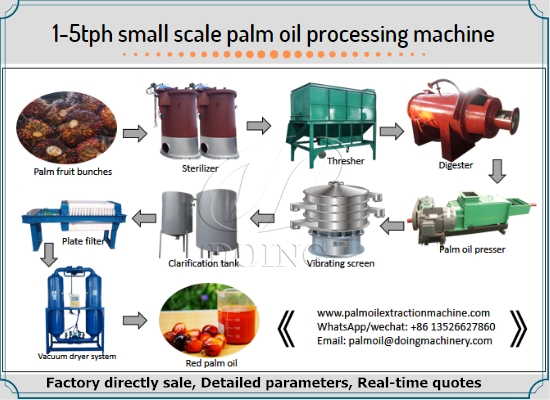

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

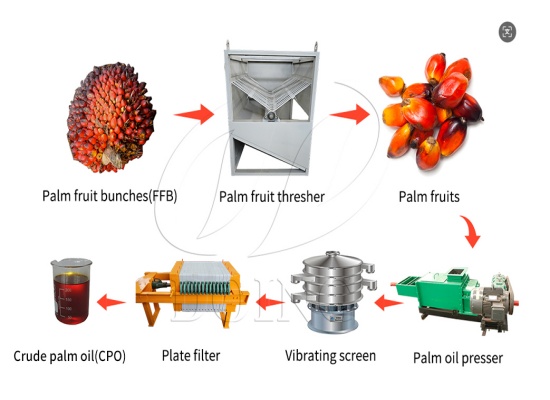

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines

recommend products