Free installation of palm oil processing plant

Introducing a new era in palm oil processing with Henan Glory Oil & Fats Engineering Co., LTD’s revolutionary free installation of palm oil processing plant. At the forefront of innovation, the company has developed a product that stands out with its primary advantage–free installation. This groundbreaking feature eliminates the need for extensive manpower, materials, and time typically required for palm oil processing plant installation, while also significantly reducing the costs associated with platform setup and civil construction.

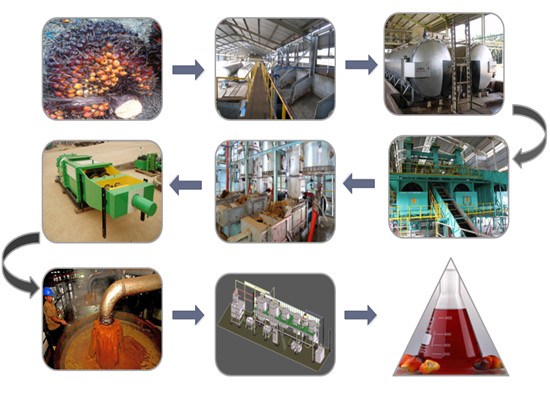

The free installation of palm oil processing plant is meticulously designed and packaged into three major frameworks, which only require three cubic containers for transportation. The following is a detailed free installation of palm oil processing plant introduction.

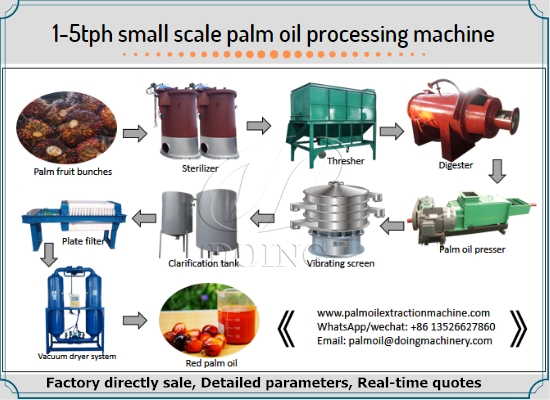

First Framework: Sterilization Section

Since our palm oil processing employs a steaming fermentation process. Therefore, the free installation of palm oil processing plants included in this framework are one hot water tank and three sterilization tanks. Among them, the hot water tank is used to hold hot water to provide the required hot water and heat source for the entire palm oil processing process. The remaining three sterilization tanks are dedicated to palm fruit sterilization. Each sterilization tank has a biofuel compartment at the bottom, a hot water boiler in the middle, and four fruit cages on the top. By utilizing the principle of steaming buns, the palm fruits then need to be sterilized in these sterilization tanks for 2.5-3 hours before entering the next step of palm oil processing. In addition, the extra-high part of the framework as well as the side fence and staircase parts need to be removed separately. It is worth mentioning that the loading and unloading of palm fruits is assisted by a bridge crane, and its flexible screw connection can be disassembled during transportation and reassembled conveniently at your site.

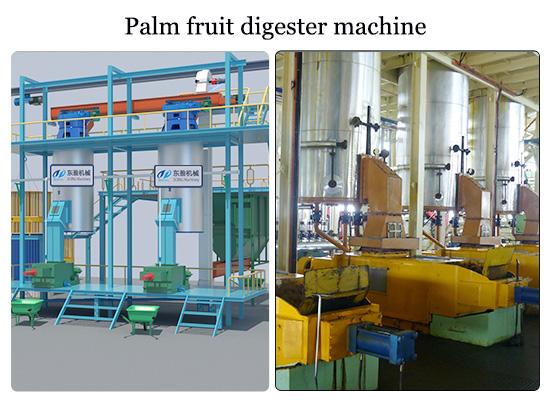

Palm fruit steaming and sterilization section

Palm fruit steaming and sterilization section

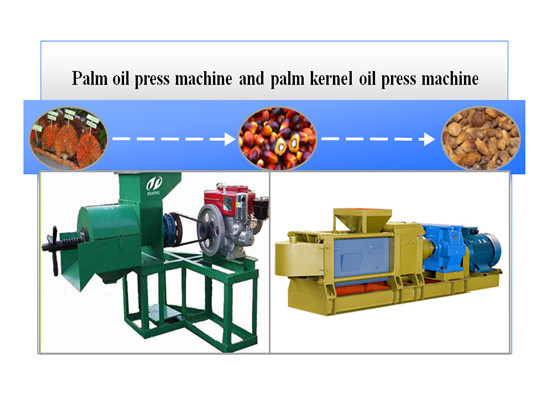

Second Framework: Threshing and Pressing Section

The free installation of palm oil processing plants included in the framework are a drum type palm fruit threshing machine, a double screw palm oil press machine modified for digesting, and an ordinary 1tph double screw palm oil press machine. Among them, due to the height limit of the container and the height of the vertical digesting tank is too high, Henan Glory Company's engineers modified the double screw palm oil press machine to enable it to digest the palm fruits. Then the digested palm fruits and the oil are put into the 1tph double screw palm oil press machine below for pressing.

Palm oil digesting and pressing section

Palm oil digesting and pressing section

The 1tph double screw palm oil press machine is crafted from 2Cr13 wear-resistant alloy steel, utilizing a one-piece casting process for durability. With normal maintenance, they can last six months to a year. Structurally, the tail end is equipped with a gearbox combined with a hydraulic pump station, driving two screws to rotate opposite each other, engaging the stirring blades to extract oil. As the oil progresses towards the exit, the blade gaps become narrower, increasing pressure, reducing oil residue, and minimizing the risk of clogging. For enhanced operability, our hydraulic pump station features button adjustment, and we utilize a hard-toothed gear reducer for superior material quality and extended lifespan.

Third Framework: Crude Palm Oil Filtration and Drying Section

The free installation of palm oil processing plants included in this framework include a sand settling tank, a rotary vibrating screen, a plate and frame filter and a vacuum drying system. Among them, the sand settling tank is used to remove heavier impurities such as mud and sand in the palm oil, the rotary vibrating screen is used to remove suspended fibers in the palm oil, and the plate and frame filter is used to remove fine impurities in the palm oil, so as to obtain pure crude palm oil. They work together to ensure that the impurity removal rate in the palm oil exceeds 99%. In addition, the free installation of palm oil processing plant required for the vacuum drying system is a vacuum dehydration pot, which has a resistance wire for electrical heating and a water jet pump for vacuuming to prevent the palm oil from being oxidized at high temperature, which can extend the shelf life of the crude palm oil and make the final water content reach 4-5%.

Complete free installation of palm oil processing plant

Complete free installation of palm oil processing plant

Remarkably, all three frameworks are pre-installed at our factory before transportation. This means you can bypass complex civil construction. All you need is a flat site with access to water and electricity. Upon arrival, the free installation of palm oil processing plant requires only simple positioning. Currently, this free installation of palm oil processing plant is available in a one-ton-per-hour capacity.

In conclusion, Henan Glory Oil & Fats Engineering Co., LTD is committed to pushing the boundaries of palm oil processing with our cutting-edge technology. Our free installation of palm oil processing plant represents a significant leap forward, offering unparalleled convenience and efficiency. Join us in embracing the future of palm oil processing today!

Leave A Message

If you want to know more information about Free installation of palm oil processing plant . pls kindly leave your phone number, We will back to you ASAP once we got your message.

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines