Crude palm kernel oil refinery processing machine

Crude palm kernel oil refinery processing machine is ideal choice for making standard edible oil. It adopts scientific palm oil refining methods for refining edible oil , which can effectively remove the impurities in crude palm kernel oil.

Henan Doing company is specialized in palm kernel oil refinery processing machine. We can provide the palm kernel oil refinery processing machine from 1 ton to 500 tons per day.

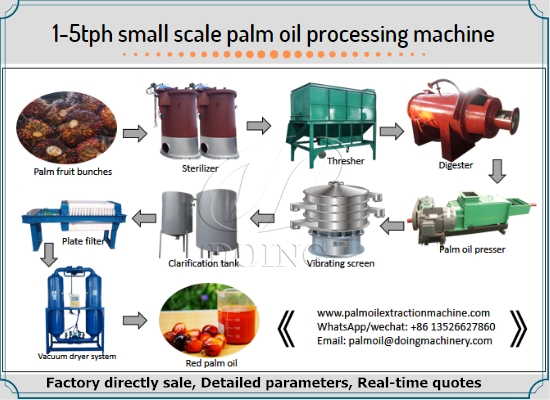

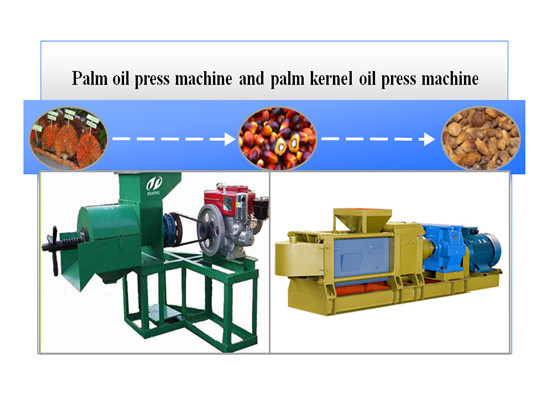

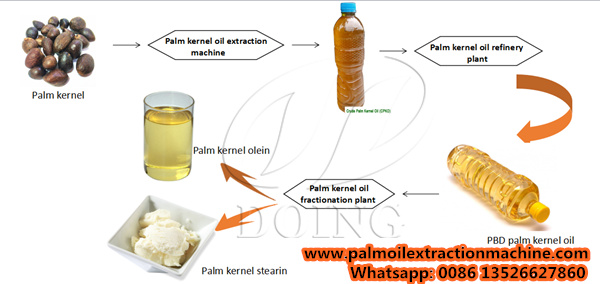

From palm kernel to crude palm kernel oil , we need palm kernel oil extraction machine; from crude palm kernel oil to refined palm kernel oil, we need palm kernel oil refining machine; from refined palm kernel oil to palm kernel olein and palm kernel stearin, we need palm kernel oil fractionation plant.

From palm kernel to crude palm kernel oil , we need palm kernel oil extraction machine; from crude palm kernel oil to refined palm kernel oil, we need palm kernel oil refining machine; from refined palm kernel oil to palm kernel olein and palm kernel stearin, we need palm kernel oil fractionation plant.

Recommend reading: Palm kernel oil extraction machine; Palm kernel oil refinery plant; ]

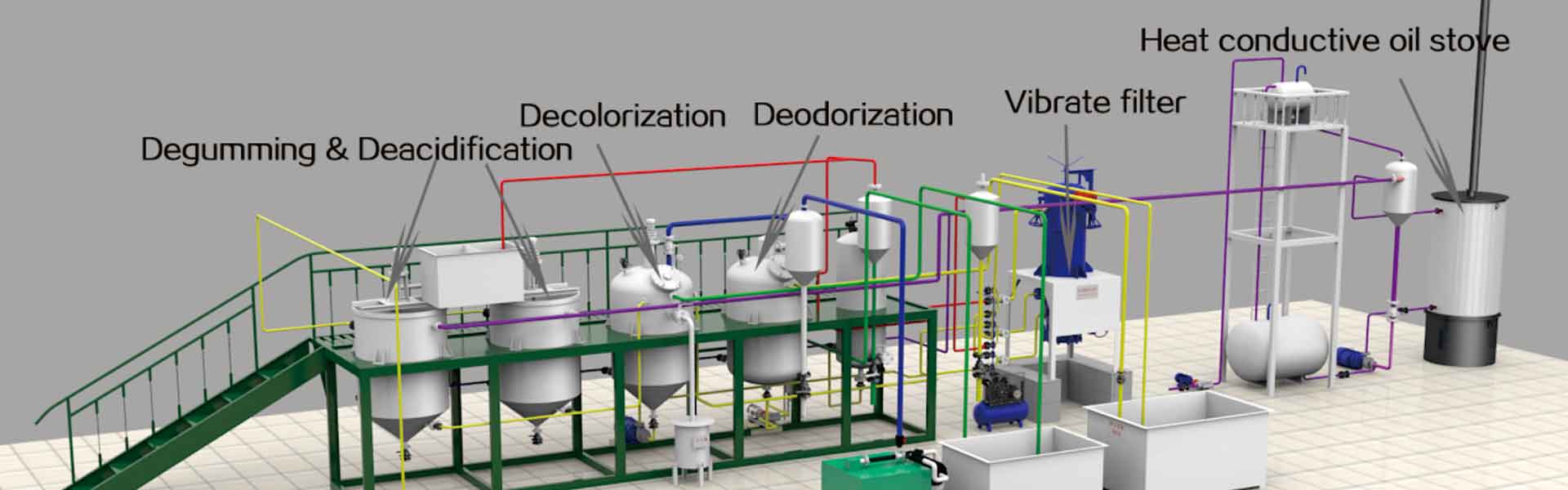

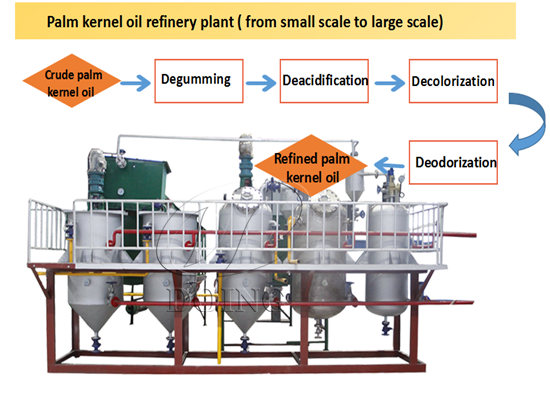

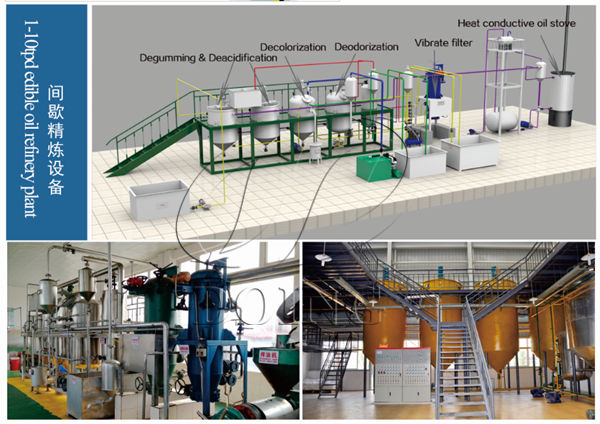

Application: Our palm kernel oil refinery processing machine is suitable for refining various crude edible oil . For example, rice bran oil refining , peanut oil refining/refinery, soybean oil refining, sunflower oil refining and so on. Usually the palm kernel oil refinery machine includes four parts: deacidification, decolorization, deodorization and palm kernel oil fractionation. Through the palm kernel oil refinery processing machine, we can get high quality palm kernel oil.

Our palm kernel oil refinery processing machine can refine the above vegetable oil

Our palm kernel oil refinery processing machine can refine the above vegetable oil

Purpose of palm kernel oil refinery processing machine:

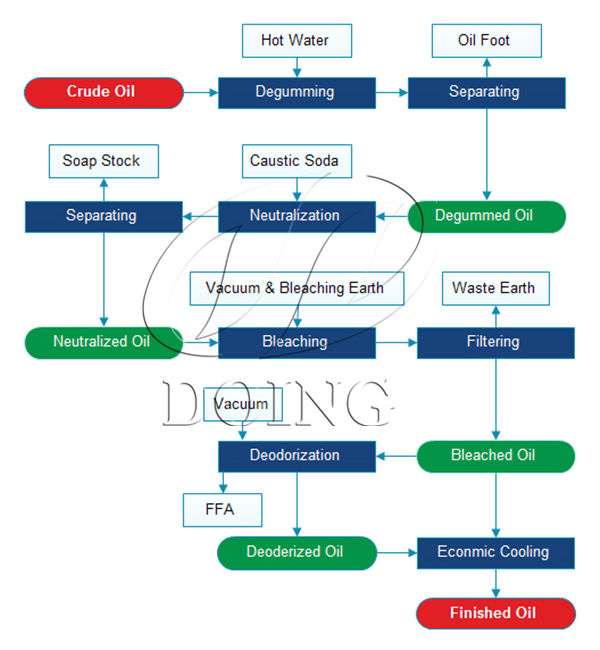

Vegetable and Animal Oils and Fats have impurities such as Moisture, Solids (Insolubles), Gums (Lecithins), Free-Fatty Acids (FFA), and Compounds of Sodium, Potassium, Magnesium, Calcium, and other metals. These impurities must be removed to improve the functionality of the oils. Other characteristics of oils (such as Color, odor, and taste) are also considered impurities by modern consumers. These impurities are removed in a series of palm kernel oil refinery steps such as degumming (to remove gums), neutralizing (to remove FFA), bleaching (to remove color), deodorizing (to remove odor and taste), and fractionation (to separate palm kernel olein and palm kernel stearin from refined palm kernel oil ). In a words, palm kernel oil refinery processing machine is used for removing the harmful impurities in the crude palm kernel oil , it can effectively improve palm kernel oil quality.

Work flow of palm kernel oil refinery processing machine:

Work flow of palm kernel oil refinery machine

Work flow of palm kernel oil refinery machine

Palm kernel oil refinery process description:

A.Degumming:this is the most important section of palm kernel oil refinery processing machine. Vegetable Oils is to remove Gums. All oils have hydratable and non-hydratable gums.a. Water Degumming: Hydratable gums are removed by treating oils with water and separating the gums. The gums can be dried to produce lecithin.

b. Acid Degumming: Non-Hydratable gums are removed by treating oils with acids and separating the gums.

B.Deacidification:using alkali like (NaOH) to neutralize FFA in oil, during this process it will produce soapstock , then separating it from the oil.

C.Decolorization:because there is pigment in crude oil, the oil color is dark. In order to improve oil color, we need to using the active clay to absorb the pigment away , then using vibrating filter to separate the waste clay. If you want to get light color oil, you need to add more active clay. Customer can accord to his requirement to control the oil color.

D.Deodorization and Dehydration:the crude palm kernel oil smells not good, it will affect of oil storge and selling prices. So we usually use the direct steam to take odors. At the meanwhile, there is about 0.5% water content in refined oil, because the high temperature in the deodorization tower or pot, dehydration section is also finished in this part of palm kernel oil refinery processing machine.

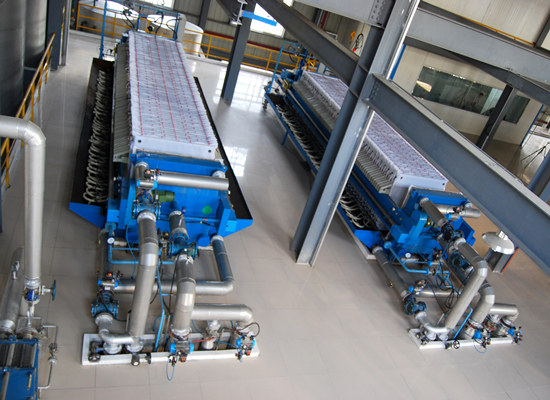

E.Fractionation:palm kernel oil fractionation goes through the control of palm oil cooling and crystallization to make separation of palm oil into low melting point liquid (soft fat) and high melting solid (stearin). Fractionation of palm kernel oil can be divided into two fractions: stearin (palm kernel stearin), soft fat (palm kernel olein).

Small scale palm kernel oil refinery plant (with capacity 1-20tpd)

Small scale palm kernel oil refinery plant (with capacity 1-20tpd)

Advantages of palm kernel oil refinery processing machine:

Wide application for various vegetable oil, even animal oil, fish oil, etc.

Low investment but with compelte function of palm kernel oil refining process.

Less land request with light weight and can be movable.

Easy installation and Safe Operation.

Once you have problems with palm kernel oil refinery processing machine, please refer to above palm kernel oil refinery plant working priciple instructions, and if you are interested in palm kernel oil refinery business, our supplied palm kernel oil refining machine can meet your demands.

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines