Palm kernel oil refining process

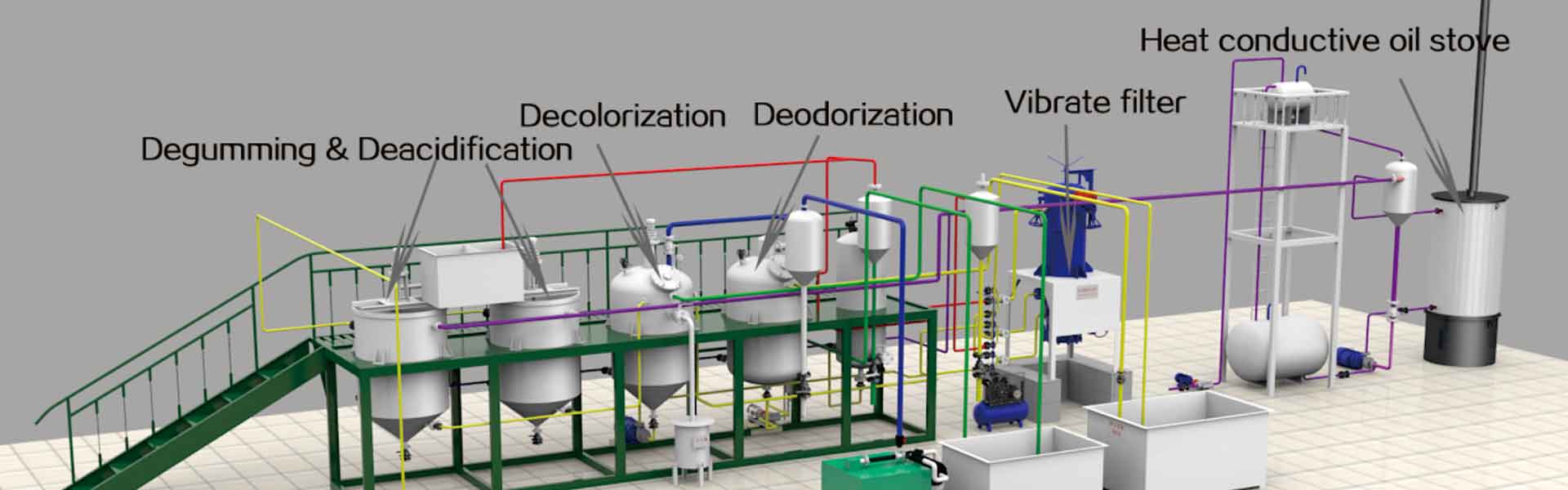

Palm kernel oil refining process is a extremely complicated process.Palm kernel oil refining process consists of palm kernel oil degumming process.palm kernel oil deacidification process,palm kernel oil decolorization process and palm kernel oil deodorization process.And our palm kernel oil refining machine is widely used in peanut oil refining ,soybean oil refining,corn germ oil refining ,rapeseed oil refining, cottonseed oil refining and palm oil refining.

Palm kernel oil refining machine

Basic information of palm kernel oil refining machine:

Product name: palm kernel oil refining

Processing material: crude palm kernel oil

Capacity: 1-600T/D

Type:1-20tpd batch type palm kernel oil refining machine, 20-50tpd semi-continuous palm kernel oil refining machine, 50-600tpd fully continuous palm kernel oil refining machine;

Major Equipment: degumming tank, heat exchanger, decolorization tower, deodorization tower

Application:palm kernel oil refining machine is widely used in peanut oil refining ,soybean oil refining,corn germ oil refining ,rapeseed oil refining, cottonseed oil refining and palm oil refining

Palm kernel oil refining machine can refine the above oilseeds

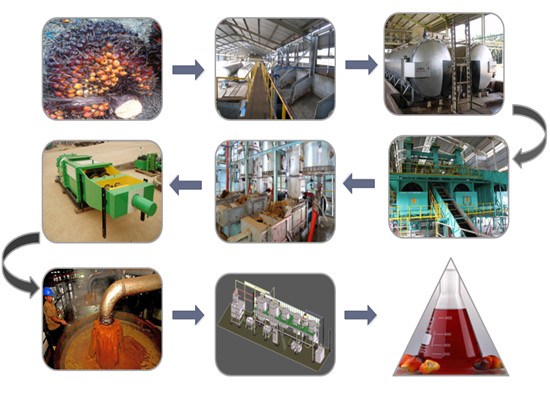

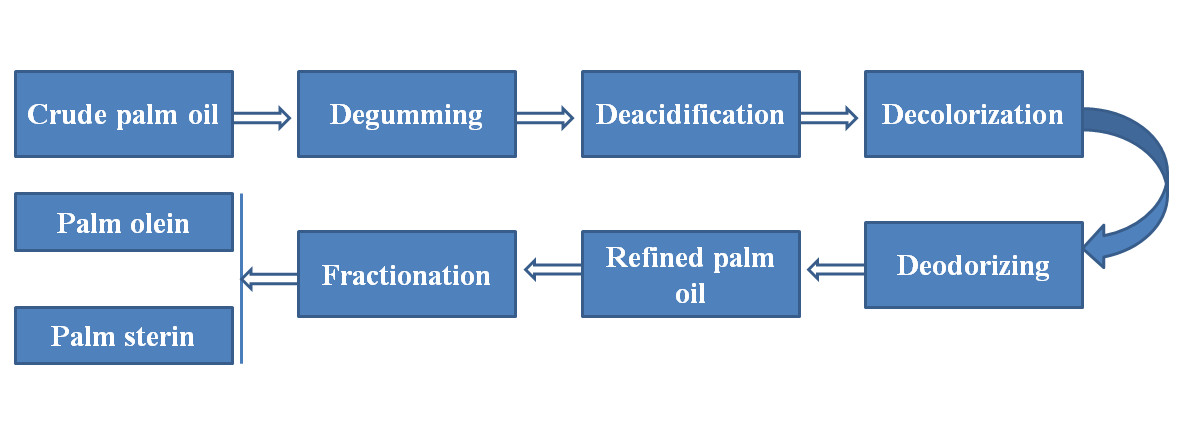

Palm kernel oil refining process is as below:

Crude palm kernel oil – degumming – deacidification – decolorization – deodorization – fractionation– palm kernl oil product

Palm kernel oil refining process

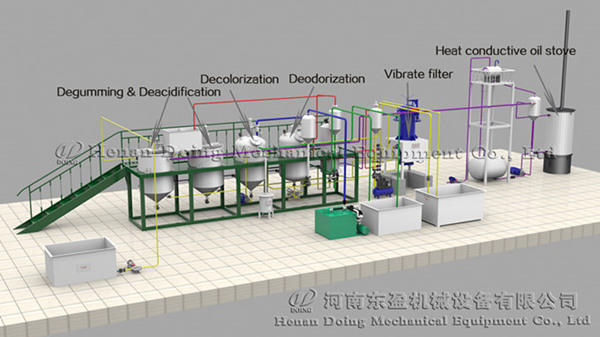

Major process during palm kernel oil refining process:

Neutralization pot: For acid refining, alkali refining and water washing.

Decolorization pot: Bleach oil and remove pigment.

Deodorization pot: Remove odor of oil(Made of stainless steel).

Heat conduction oil furnace: Provide heat energy for palm kernel oil refining process,the temperature can reach 280℃.

Vacuum pump: Provide vacuum degree for decolorization and deodorization,up to above 755mgHg.

Air compressor: Dry decolorized bleaching clay.

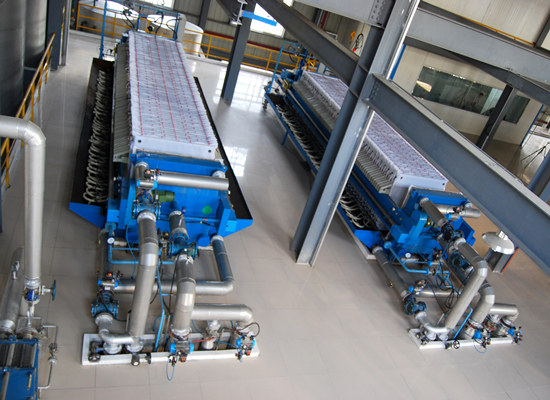

Filter press: Filter bleaching clay.

Steam generator: Provide steam for deodorization & distillation

Main equipment of samll scale palm kernel oil refining machine

Simple introduction of palm kernel oil refining process:

● Decolorization. Whit clay makes continuously decolorization of crude palm kernel oil, and enters into filter for filtration.

● No need of degumming. Physical oil refining is applicable because of low gum content inside palm kernel oil.

● High vacuum deacidification. Gas supported heat-conducting oil boiler and packed tower make high vacuum deacidification from crude palm kernel oil.

● Fat acid Condensing recovery. Stainless steel recycled water is adopted to make direct condensing recovery of fat acid.

As a prominent edible oil refinery plant manufacturer who is devoted to processing pure edible oil for worldwide customers, we can provide professional technical support and manufacture first rate oil machines for your palm kernel oil refining process machinery. We can provide turnkey palm kernel oil refining solution with capacities from 1-2000T/D. And our palm kernel oil refining process machinery capacity can be customized. The complete oil refining plant can work independently or together with whole palm kernel oil production line.

Leave A Message

If you want to know more information about Palm kernel oil refining process . pls kindly leave your phone number, We will back to you ASAP once we got your message.

-

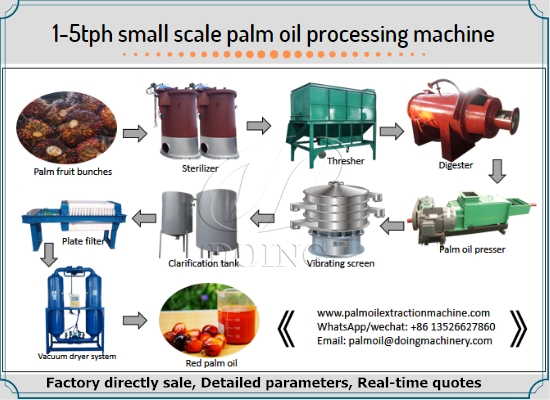

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

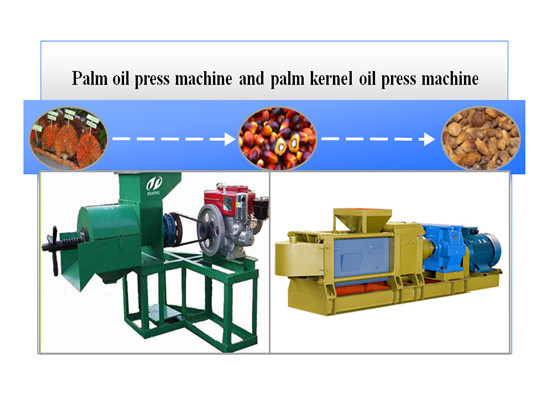

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines