Chemical vs. Physical Refining for Palm Oil: Which Process is Best for Your New Refinery?

When setting up a new palm oil refinery, one of the most important decisions you'll face is whether to use chemical refining or physical refining. Each process has its own set of advantages and considerations that will affect both your product quality and overall operational efficiency. Here’s a breakdown of both refining processes to help you decide which process is best for your new palm oil refinery:

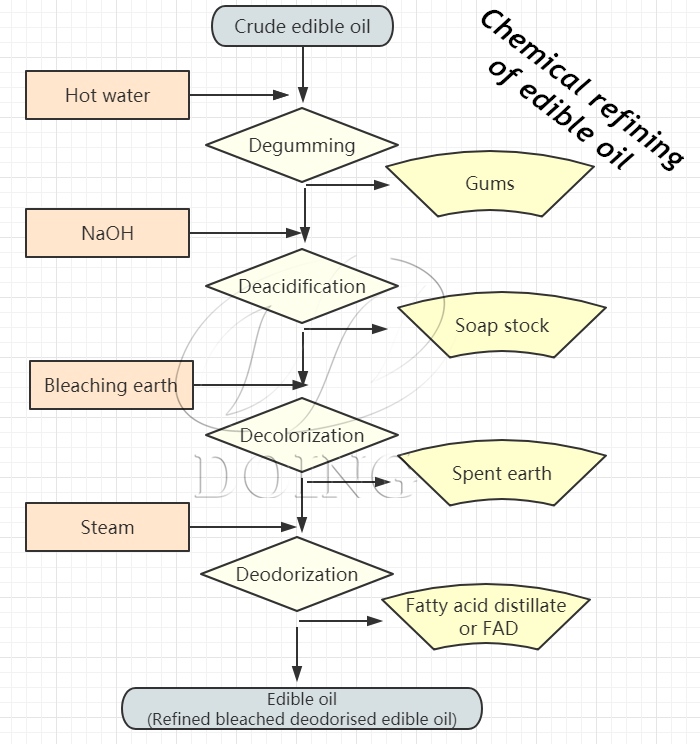

Ⅰ. Chemical Refining for Palm Oil:

Chemical refining for palm oil is a process that uses chemicals to remove impurities from crude palm oil (CPO). It involves several stages, including neutralization of the free fatty acids contained in palm oil with alkali (usually sodium hydroxide), bleaching with absorbent clay, and deodorizing with steam and vacuum.

Chemical refining for palm oil

Chemical refining for palm oil

1. Process Overview:

(1) Degumming: Removes phospholipids and other impurities from the oil.

(2) Deacidification: Alkali is added to neutralize free fatty acids (FFAs) in the oil, which is critical to improving the oil’s shelf life and cooking properties.

(3) Decolorization: Activated clay or other adsorbents are used to remove color pigments and some impurities.

(4) Deodorization: Steam distillation is used to remove any unwanted odors or flavors.

2. Advantages of Chemical Refining:

(1) Effective for High-Quality Crude Palm Oil: Chemical refining is well-suited for crude palm oil with low free fatty acid (FFA) content.

(2) Higher Sensitivity to Raw Material Quality: Chemical refining has high requirements on raw material quality and requires strict control of FFA, phospholipid and moisture content.

(3) Improved Shelf Life: Chemical refining can significantly improve the oxidative stability of palm oil and extend their shelf life by neutralizing free fatty acids and combining with subsequent decolorization and deodorization processes.

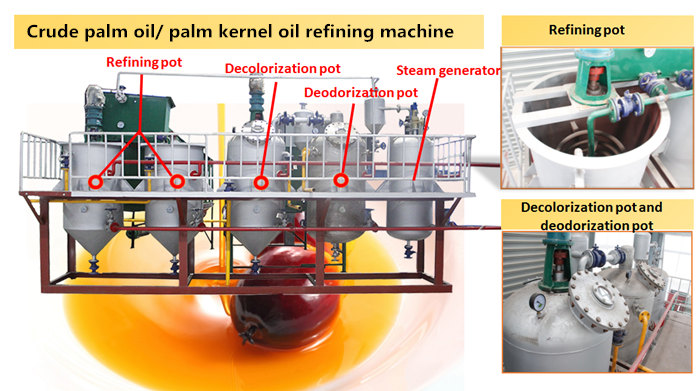

Palm oil chemical refining equipment

Palm oil chemical refining equipment

3. Disadvantages of Chemical Refining:

(1) Chemical Use: The use of chemicals such as alkali may raise environmental concerns, and waste disposal needs to be managed carefully.

(2) Higher Operating Costs: Due to the use of chemicals and the complex refining steps, chemical refining tends to be more expensive in terms of operating costs.

(3) Environmental Impact: The process generates chemical by-products that must be handled and disposed of properly, which can increase the environmental footprint.

(4) Oil Loss: During the alkali refining process, some neutral oil will be wrapped in the soap stock and taken away, resulting in a decrease in yield.

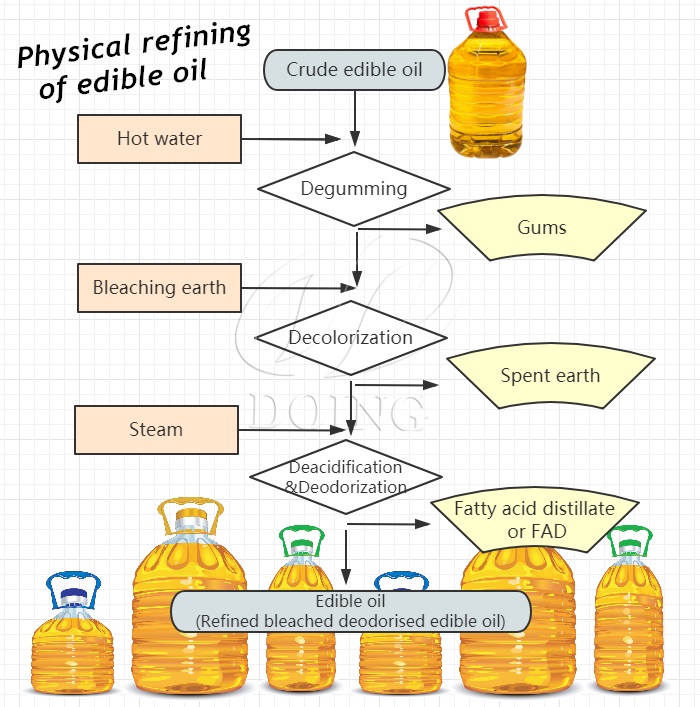

Ⅱ. Physical Refining for Palm Oil:

Physical refining for palm oil is a non-chemical process that uses heat, steam and vacuum to remove impurities, such as free fatty acids, color pigments and odor, without the use of alkali or other chemicals. The primary goal is to reduce the level of FFAs and remove volatile compounds.

Physical refining for palm oil

Physical refining for palm oil

1. Process Overview:

(1) Degumming: Removal of phospholipids, usually using water or an acid process.

(2) Deacidification: Instead of using alkali, physical refining uses steam distillation or high temperatures to break down FFAs.

(3) Deodorization: The palm oil is subjected to high-temperature steam under vacuum to remove unwanted odors and flavors.

(4) Decolorization: Some systems incorporate a bleaching step, although it is not as aggressive as chemical refining.

2. Advantages of Physical Refining:

(1) No Chemicals Required: This process does not use alkali or other chemicals, making it more environmentally friendly and reducing the chemical waste generated.

(2) Lower Operating Costs: Since it does not require chemicals, physical refining generally has lower operating costs.

(3) Less Environmental Impact: With minimal chemical use, the process generates fewer harmful by-products and is more sustainable.

(4) Better for High-FFA Palm Oil: Physical refining works well for crude oils with high FFA content.

Palm oil physical refining equipment

Palm oil physical refining equipment

3. Disadvantages of Physical Refining:

(1) Higher Energy Consumption: The process requires more heat and steam, which can increase energy consumption.

(2) Limited to High-Quality Crude Palm Oil: Physical refining is more suitable for high-quality crude palm oil with low levels of impurities, because high impurities may clog the equipment or affect the separation efficiency.

Ⅲ. Key Considerations for Choosing Between Chemical and Physical Refining:

1. Crude Oil Quality:

(1) Low FFA Content: If your crude palm oil has a low FFA content, chemical refining may be the better choice as it is more effective at neutralizing FFAs.

(2) High FFA Content: If the crude oil is of lower quality, with high FFAs, physical refining can be more cost-effective and environmentally friendly.

2. Energy & Environmental Concerns:

(1) Environmental Impact: If sustainability is a priority for your new palm oil refinery, physical refining is the more eco-friendly option due to the lack of chemicals used.

(2) Energy Costs: While physical refining has the environmental advantage, it requires more energy in the form of heat and steam. If energy costs are a concern, you may need to weigh this factor.

3. Product Quality & Market Demand:

(1) Refined Oil Quality: Chemical refining tends to produce a higher-quality product with better stability, particularly when FFAs need to be neutralized.

(2) Market Preferences: Some markets may have preferences for oil that’s been refined using a chemical-free process. If your customers prioritize “natural” or “organic” products, physical refining could be a good point.

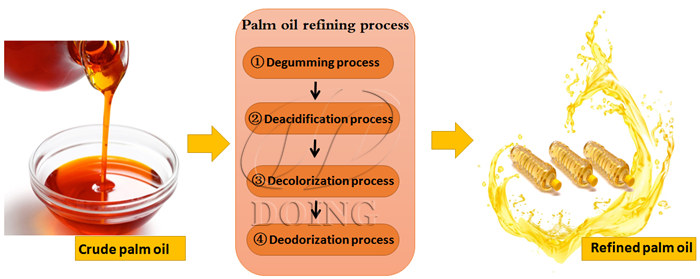

refined palm oil

refined palm oil

4. Operational Costs:

(1) Upfront Investment: Chemical refining generally requires more sophisticated equipment and processes, leading to higher capital expenditures, but it may have lower per-unit costs in the long run if operating at large scale.

(2) Operating Efficiency: Physical refining, though cheaper in terms of chemical inputs, may be less efficient in certain applications, particularly with low-quality oils.

Ⅳ. Conclusion: Which Process Is Best for Your New Palm Oil Refinery?

If your palm oil is low in free fatty acids (FFA), you seek a longer shelf life, and you are willing to pay higher operating costs for a more refined product, chemical refining is more suitable for your refinery; if you are processing low-quality crude oil (high in free fatty acids), you are focused on sustainability and reducing environmental impact, and you prefer lower operating costs and simpler processes, physical refining is more suitable for your refinery.

In short, each refining process has its place depending on the type of crude oil you are processing, your budget and your market goals. By considering these factors, you can select the refining process that aligns best with your new palm oil refinery’s capabilities and business objectives. If you have any other questions, please contact Henan Glory Company(with branch and overseas warehouse in Nigeria)!

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines