Step-by-Step Process: How a Palm Kernel Oil Refining Machine Works

When we cook with frying oil or select skincare products containing palm kernel oil, we rarely pay attention to the predecessor of these high-quality oils — crude palm kernel oil (CPKO), which was once a raw material with a dark color and unpleasant odor. The key to achieving this transformation is the palm kernel oil refining machine. Next, Henan Glory will take you to deeply understand the working mechanism and process of palm kernel oil refining machine.

Crude palm kernel oil (CPKO) contains various impurities that adversely affect its color, flavor, odor, and shelf life. The main impurities include:

Gums (phospholipids)

Free Fatty Acids (FFA)

Color pigments (e.g., carotenes)

Odor-causing volatile compounds, etc.

To remove these impurities, the refining process adopts a combination of physical and chemical refining methods. The core processes include degumming, neutralization, bleaching, and deodorization.

Step 1: Degumming

Palm kernel oil degumming machine

Palm kernel oil degumming machine

Purpose: Remove hydratable gums. These substances can cause foaming during deodorization and lead to turbidity in the final product.

Process: First, heat the crude palm kernel oil to a specific temperature (around 80°C), then add phosphoric acid and stir. The acid reacts with the gums to hydrate them, forming insoluble substances.

Result: The coagulated gums, which are denser than oil, will settle naturally and then be discharged.

Step 2: Neutralization (Deacidification)

Palm kernel oil deacidification machine

Palm kernel oil deacidification machine

Purpose: Purpose: Inhibit the increase in FFA content, remove FFAs that cause rancidity and off-flavors, while eliminating residual gums.

Process: Pump the degummed palm kernel oil into a neutralization tank and add a precisely measured sodium hydroxide (NaOH) solution. The concentration and dosage of the solution are determined based on the FFA content in the crude palm kernel oil. Then heat and fully stir the mixture — the sodium hydroxide reacts with FFAs to form soapstock.

Separation: Feed the mixture into a centrifuge. The centrifugal force generated by high-speed rotation separates the denser soapstock (and residual gums) from the palm kernel oil. The soapstock is collected as a by-product (commonly used in soap making), and the neutralized oil proceeds to the next process.

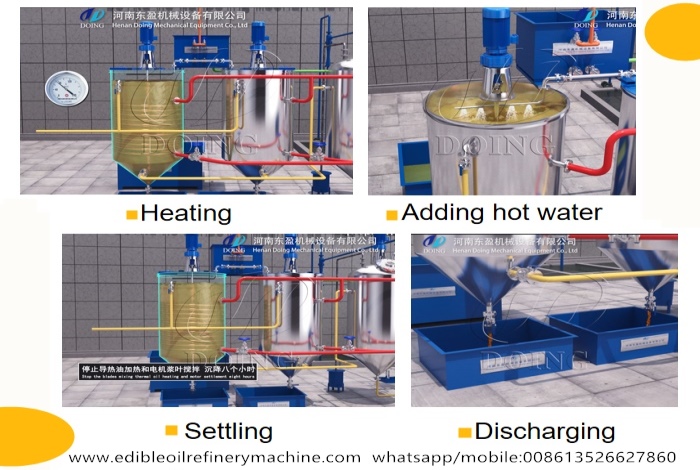

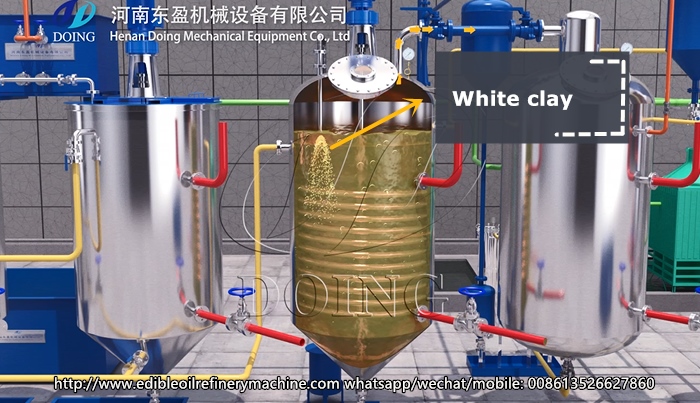

Step 3: Bleaching

Palm kernel oil bleaching machine

Palm kernel oil bleaching machine

Purpose: Remove color pigments (e.g., carotenes, chlorophyll) as well as residual soap and oxidation products.

Process: Under vacuum conditions, pump the neutralized palm kernel oil into a bleaching tank and heat it. Add bleaching earth (activated clay) — a highly adsorbent substance. During the stirring of palm kernel oil and bleaching earth, impurities are adsorbed onto the surface of the bleaching earth. For stubborn pigments and odors, a small amount of activated carbon can be added to the bleaching earth for auxiliary treatment.

Separation: After sufficient adsorption time, pump the mixture into a plate filter. Under pressure, the oil passes through the filter cloth, the spent bleaching earth adsorbed with impurities is trapped, and the clear palm kernel oil is sent to the next stage.

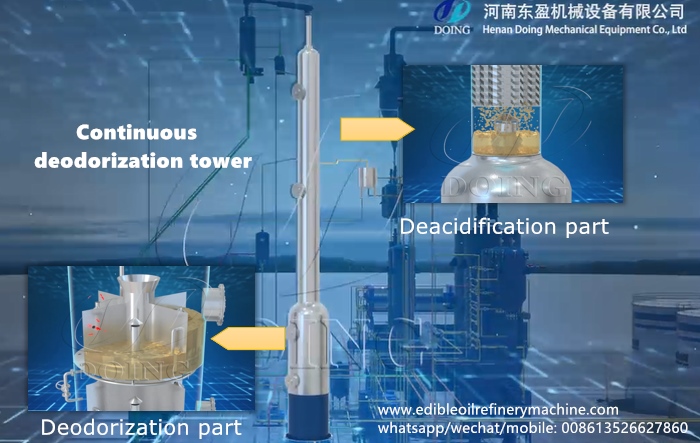

Step 4: Deodorization

Palm kernel oil deodorization machine

Palm kernel oil deodorization machine

Purpose: Remove unpleasant odors and volatile compounds — this final process produces edible palm kernel oil with a mild flavor and stable properties.

Process: This is a steam distillation process carried out under vacuum and high-temperature conditions. Pump the bleached oil into a deodorizer tower — a large vertical multi-chamber vessel. Heat the palm kernel oil to 220-250°C under high vacuum. The vacuum environment is crucial: it lowers the boiling point of volatile compounds, ensuring their removal with minimal thermal damage to the oil. Then introduce high-temperature steam into the hot oil, which carries away volatile odor-causing compounds (e.g., aldehydes, ketones).

Result: The resulting palm kernel oil has a neutral odor and flavor, and is cooled under vacuum (a process called "heat bleaching" to stabilize the final color).

Final Product

After all the above processes, the final product is refined, bleached, and deodorized (RBD) palm kernel oil. This product features a clear appearance, light color, neutral odor and flavor, excellent storage stability and cooking applicability. It can be directly used for sale or as a raw material in the food, cosmetics, and other industries.

The entire process can adopt semi-continuous or fully continuous palm kernel oil refining machine. Modern palm kernel oil processing mills usually adopt continuous systems to achieve large-scale production efficiency. If you have needs for palm kernel oil refining machine, please contact Henan Glory — we are very pleased to provide you with professional equipment and services.

PREV:Henan Glory 1T/H Plug-and-Play Palm Oil Press Unit

PREV:Henan Glory 1T/H Plug-and-Play Palm Oil Press Unit

NEXT:What Are the Factors Affecting the Quality of Palm Oil?

NEXT:What Are the Factors Affecting the Quality of Palm Oil?

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines