Palm oil mill equipment machinery

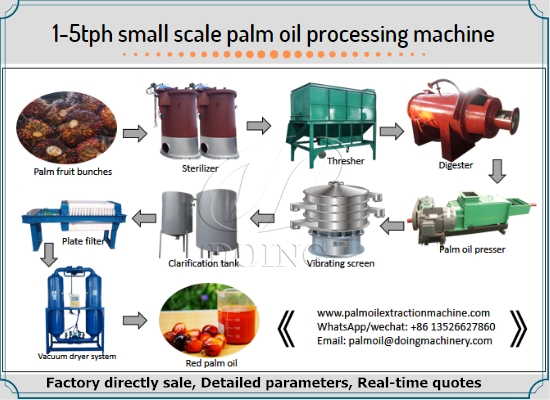

Palm oil mill equipment machinery is the main equipment in palm oil production process. Palm oil mill equipment machinery aims to extract palm oil quickly and efficiently. As a professional manufacturer of palm oil processing machine, Henan Glory Company can supply the palm oil mill equipment machinery with the input capacity from 1tons per hour to 120tonsper hour, but today, we mainly introduce the large scale palm oil mill equipment. If you are wondering what machines are needed in large palm oil mill plant and how the red palm oil is produced, please continue reading, below is a comprehensive information about palm oil mill equipment machinery.

Large scale palm oil mill plant appearance

Large scale palm oil mill plant appearance

Related parameter of palm oil mill equipment machinery:

| Product name : | Palm oil mill equipment machinery |

| Main station: | palm fruit reception station, palm fruit sterilizing station, palm fruit threshing station, palm fruit digesting & pressing station and palm oil clarification station |

| Production capacity: |

Small production line:1-2-3-5tph

Medium sized production line:10-15-20-30tph Large sized production line:50-60-80-100-120tph |

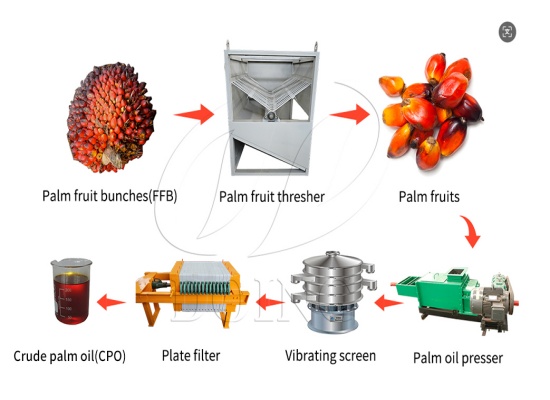

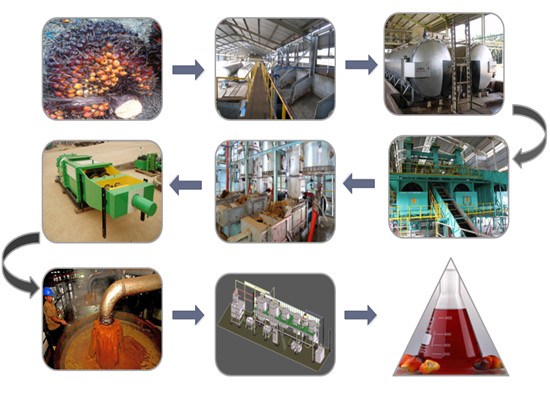

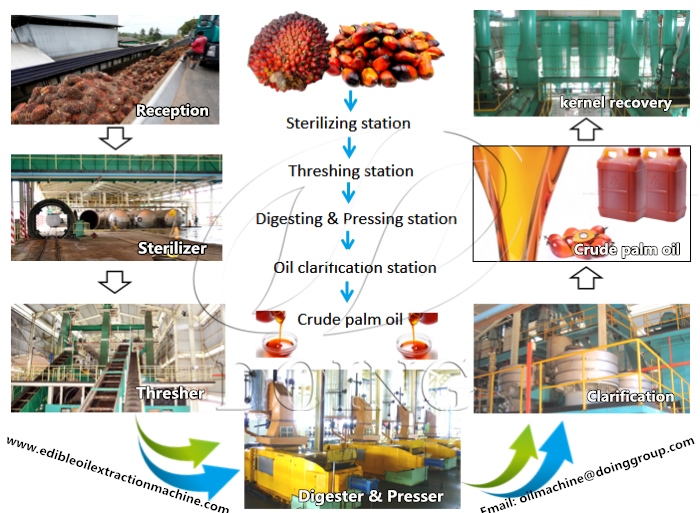

Production process of palm oil mill equipment machinery:

Palm oil production process is a complex process which includes palm fruit reception station, palm fruit sterilizing station, palm fruit threshing station, palm fruit digesting & pressing station and palm oil clarification station. Each palm fruit station works together can maximize the extraction of palm oil and help people get more profilt.Next i will introduce each station to you detailedly.

Palm oil production process flow chart

Palm oil production process flow chart

→Palm fruit reception station

Collecting the ripe fresh palm fruit bunches from the plantation and transported by trucks, then pour the FFB into the discharge door after weighed by weighbridge.

The discharge platform with sliding gate exit, every sliding gate swich is controlled by hydraulic system, which consists of hydraulic pump station and hydraulic cylinder. Start the control valve to open the gate of the discharge door, then the palm fruits falls into palm fruit bunches conveyor.

As for discharge platform, some palm oil mill plant use concrete structure, but it’s not good for cleaning. Now we adopt steel material, fence structure, it is easy cleaning, some impurity will drop down to a conveyor, impurity will conveyed to outside.

Palm fruit reception station

Palm fruit reception station

→Palm fruit sterilizing station

Then, the FFB will be transported to sterilizing tank by scraper conveyer to begin the sterilizing process. The purpose of sterilizing process is to break the enzymes in palm fruit, and to avoid the increasing of the FFA content in crude palm oil. Usually, the sterilizing time is 90~120mins, the temperature is 130~145℃.

Sterilizer can be design as owner’s requirement, horizontal sterilizer or vertical sterilizer all is optional.

Related reading: Horizontal sterilizer, vertical sterilizer and tilting sterilizer

Palm fruit sterilizer machine

Palm fruit sterilizer machine

→Palm fruit threshing station

Palm fruit thresher ia another important palm oil mill equipment machinery, which is used for separate empty fruit bunch and palm fruit. According to the palm oil mill capacity, we can design the thresher capacity, usually we have a spare one, in case one of them not work.

The palm fruit thresher mainly adopts drum type structure. There is a rotary drum inside of the palm fruit threshing machine. The separated palm fruit is sent to the pressing station. Empty palm fruit bunches are discharged from the other side of the palm fruit thresher, and then the EFB is transported to the yard , or to palm plantation as fertilizer or slipcover.

Palm fruit thresher machine

Palm fruit thresher machine

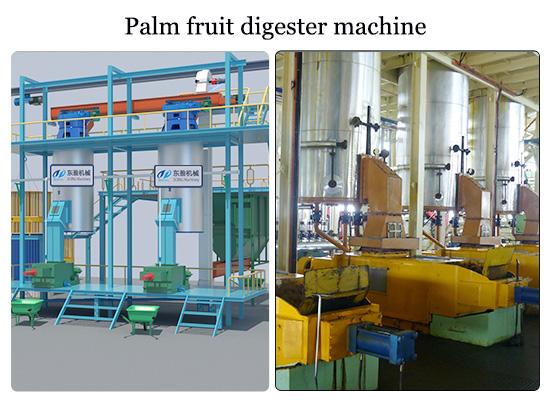

→Palm fruit digesting & pressing station:

Palm fruit digesting & pressing station is made of two different palm oil machines, they are pam fruit digester machine and double screw palm oil press machine.

After palm fruit sterilizing process, the sterilized palm frutis be conveyed to palm fruit digester machine.There are blades in palm fruit digester, blades will be controlled by motor which is on the top of palm fruit digester to crush palm fruits to palm pulp, besides we will fill the steam in palm fruti digester for heating. Palm fruit pulp cell can be destroyed under the high temperature condition, after that we can get higher oil yield.

Palm fruit digester machine

Palm fruit digester machine

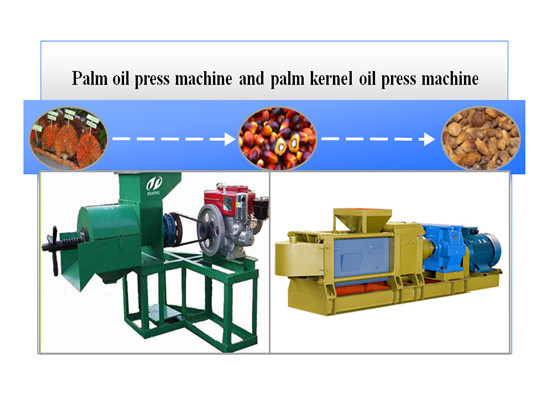

And then, the palm pulp falls into the double screw palm oil press machine for pressing, compared to other screw cooking oil press machine, this double screw palm oil press machine is controlled by hydraulic control system. Hydraulic automatic control system can automatically adjust spaces between screws to maximize squeeze palm oil and guarantee the oil yield. After pressing, we can get the mixture of palm oil and palm nuts and fibers. The crude palm oil needs to be purified, the palm nut and fiber impurities can be processed by palm nuts recovery machine. Then palm nut is stored for deep processing, and the separated fiber are used as the boiler fuel.

Related reading:1tph, 5tph, 10tph, 15tph double screw palm oil press machine

Palm oil press machine

Palm oil press machine

→Palm oil clarification station:

A mixture of oil, water, and solids from the bunch fibres is delivered from the palm oil digesting & pressing station to a clarification tank of palm oil mill plant. In the conventional process, separation of the oil from the rest of the liquor is achieved by settling tanks based on gravity. The mixture containing the crude oil is diluted with hot water to reduce its viscosity. A vibrating screen helps remove some of the solids. The oil mixture is heated to 85-90°C and allowed to separate in the clarification tank. A settling time of 1-3 h is acceptable. Oil from the top is skimmed off and purified in the centrifuge prior to drying in vacuum dryer. The final crude palm oil is then cooled and stored. The lower layer from the clarification tank is sent to the centrifugal separator where the remaining oil is recovered. The oil is dried in vacuum dryers, cooled and sent to storage tanks.

Related reading: Palm oil clarification station

Crude palm oil clarification machine

Crude palm oil clarification machine

Henan Glory Company is an enterprise integrating engineering R&D, equipment manufacturing and installation, project contracting, technical service and international trading. We are mainly engaged in palm oil processing machine, palm kernel oil processing machine, palm oil refinery and fractionation plant.

With our development in palm oil processing field, our company can offer advanced technology and our market have expand to Malaysia and Indonesia and many African countries. Our company not only can offer turn-key project, but also can offer old palm oil mill update or reconstruction service and abroad engineering service. If you are intersetd in palm oil palm oil mill equipment machinery and want to get the detailed parameters and latest promotion price list, welcome to contact us. To let you a clearer idea of the scope of our palm oil mill equipment machinery, now I will enumerate them for you

Main business:

Palm oil extraction machine:

1-2-3-5-10TPH small scale palm oil processing machine;

10-15-20-30TPH medium scale palm oil processing machine;

30-45-60-80-120TPH large scale palm oil processing machine;

Palm kernel oil extraction machine:

0.5-1-2TPH small scale palm kernel oil processing machine;

10-600TPD large scale palm kernel oil processing machine;

Palm oil /Palm kernel oil refinery and fractionation plant:

1-2-3-5-10TPD palm oil/palm kernel oil refinery machine;

10-15-20-25-30-50TPD palm oil/palm kernel oil refinery machine;

50-80-100-150-300-600TPD fpalm oil/palm kernel oil refinery machine;

Leave A Message

If you want to know more information about Palm oil mill equipment machinery . pls kindly leave your phone number, We will back to you ASAP once we got your message.

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines

-

What Are the Benefits of Using a Professional Vegetable Oil Refining Machine

What Are the Benefits of Using a Professional Vegetable Oil Refining Machine

-

Henan Glory 1T/H Plug-and-Play Palm Oil Press Unit

Henan Glory 1T/H Plug-and-Play Palm Oil Press Unit