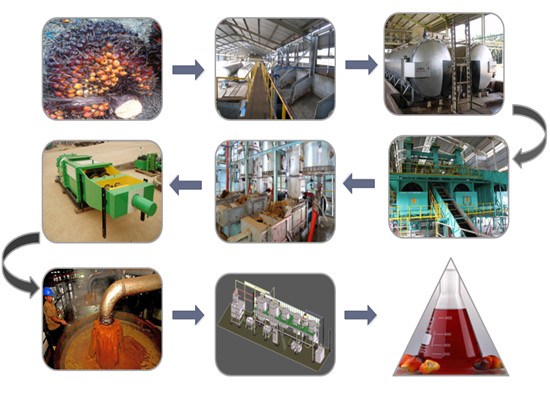

Crude palm oil extraction process—palm oil processing steps introduction

Palm oil is extracted from fresh fruit bunches by mechanical pressing method. Today's modern palm oil extraction process is developed on the basis of large-scale palm oil extraction processes in Indonesia, Malaysia, etc. It has the characteristics of high degree of automation, high oil yield.

Palm oil extraction machine 3D animation image

Palm oil extraction machine 3D animation image

In fact, the quality of crude palm oil depends not only on the variety of palm fruit, but also on the treatment of palm fruit after harvesting, particularly on the processing process of the palm fruits. Next I will introduce you how to extract palm oil at large scale palm oil mill plant?

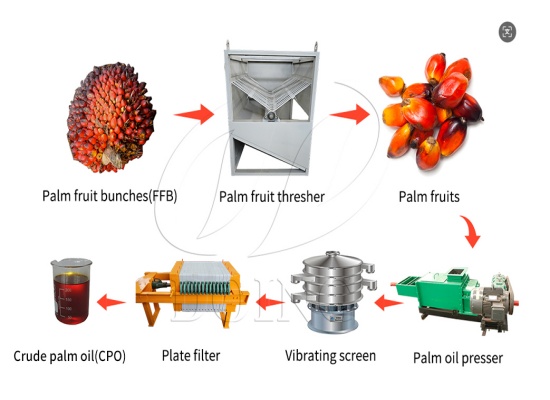

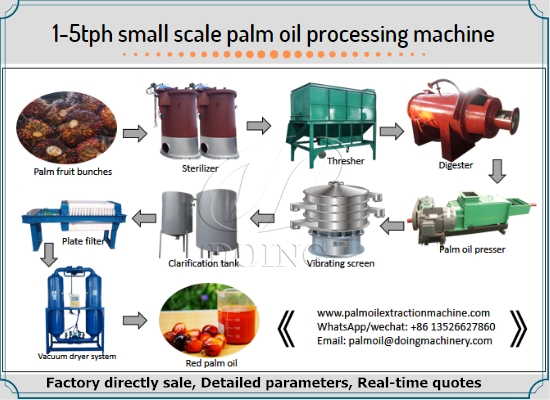

Palm oil extraction process comprises of sterilization, stripping, digesting, pressing, clarification, purification, drying and storage. First, collecting the ripe fresh cluster from the orchard, and then transmit them to the palm oil mill. Second, sterilizing palm fruit by using steam or hot water. Because, sterilizing process is crucial to the final oil quality. Sterilization inactivates the lipases in the fruits, and prevents build-up of free fatty acids (FFA). In addition, steam sterilization of the FFBs facilitates fruits being stripped from the bunches. It also softens the fruit mesocarp for digestion and release of oil, and conditioning of nuts to minimize kernel breakage. Third, threshing palm fruit from palm fruit bunches. The purpose of threshing in palm oil extraction process is to separate the palm fruit from the FFB.

Related reading: Horizontal sterilizer, vertical sterilizer and tilting sterilizer

Palm fruit sterilizer machine and palm fruit thresher machine

Palm fruit sterilizer machine and palm fruit thresher machine

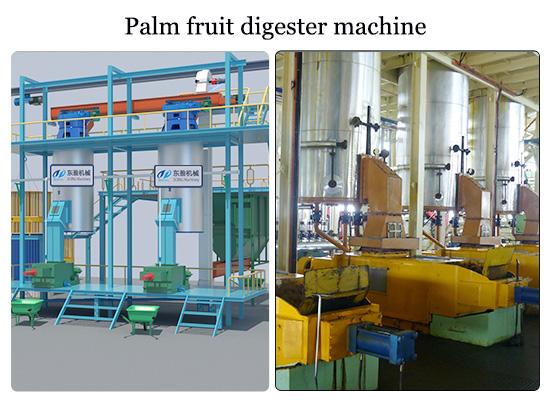

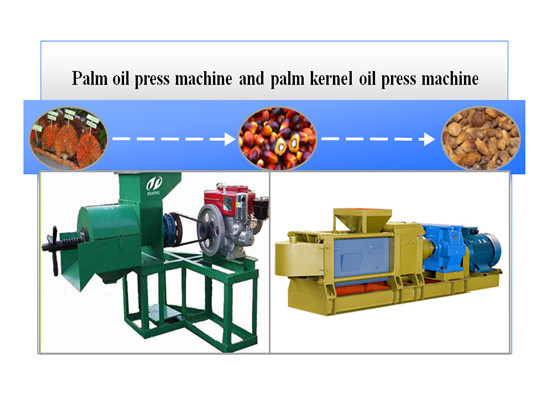

After threshing, the palm fruits will be moved into a digester, where, the palm fruits are reheated to loosen the pericarp. The steam heated vessels have rotating shafts to which are attached stirring arms. The palm fruits are rotated about, causing the loosening of the pericarps from the nuts. Then, crashed palm pulp is sent to continuous screw palm oil press machine. After pressing, the palm oil is divided into two parts: the mixture of oil and the press cake. And then, the crude palm oil will be pumped into palm oil clarifying section to purify the palm oil. When the above operations are completed, the final crude palm oil will be cooled and stored. But in order to extend the life of palm oil, we also usually send the palm oil to a vacuum dryer to remove moisture. Then the oil is cooled and sent to storage tanks.

Palm oil pressing machine and palm oil clarification equipment

Palm oil pressing machine and palm oil clarification equipment

Our company, Henan Glory Company, devotes to provide complete equipment solutions for palm oil production and palm oil refining, including palm oil mill plant layout design, palm oil machine manufacturing, palm oil equipment debugging and installation. If you are interested in it, please contact us to get the latest quotation!

Leave A Message

If you want to know more information about Crude palm oil extraction process—palm oil processing steps introduction . pls kindly leave your phone number, We will back to you ASAP once we got your message.

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines

-

What Are the Benefits of Using a Professional Vegetable Oil Refining Machine

What Are the Benefits of Using a Professional Vegetable Oil Refining Machine

-

Henan Glory 1T/H Plug-and-Play Palm Oil Press Unit

Henan Glory 1T/H Plug-and-Play Palm Oil Press Unit