What is the unit operation involved in palm oil processing?

Palm oil, a staple commodity in global agriculture, is extracted from the fruits of the oil palm trees (Elaeis guineensis). The processing of palm oil involves a series of unit operation that transform the raw palm fruit bunches into the refined palm oil we know. The unit operation in palm oil processing include harvesting, sterilization, threshing, digestion, pressing, clarification, refining, and fractionation. Here, we delve into the unit operation in palm oil processing.

1. Harvesting:

The first step in palm oil processing is the harvesting of ripe palm fruits from the oil palm trees. The process typically done manually by cutting down the palm fruit bunches or mechanically using harvesting machines to ensure the efficient collection of the palm fruits.

The photo of palm fruits and crude palm oil

The photo of palm fruits and crude palm oil

2. Sterilization:

After harvesting, the palm fruit bunches are sterilized to prevent enzymatic degradation and microbial contamination. Steam under high pressure is commonly used for sterilization to ensure the quality and safety of the palm oil.

3. Threshing:

Threshing is the process of separating the palm fruits from the bunches. This can be achieved through mechanical means or manual labor to extract the fruits efficiently.

Small scale palm oil processing machine

Small scale palm oil processing machine

4. Digesting and Pressing:

The palm fruit is then subjected to a digestion process to break down the pulp and release the oil. After digesting, the palm fruits are pressed to extract the crude palm oil. The screw palm oil press machine provided by Henan Glory Company with high oil rate and low loss.

The screw palm oil press machine provided by Henan Glory Company

The screw palm oil press machine provided by Henan Glory Company

5. Clarification:

The crude palm oil undergoes a clarification process to remove impurities and solids. Centrifuges or filter presses are commonly used for this step to ensure the purity of the palm oil.

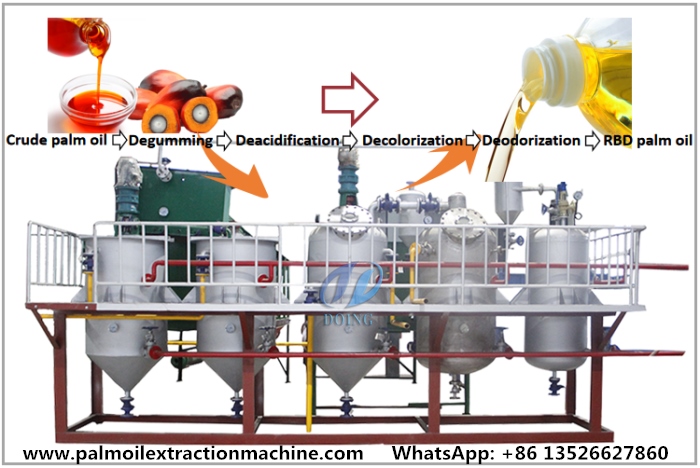

6. Refining:

Refining is a critical unit operation in palm oil processing that involves further processing the clarified oil to improve its quality. Degumming, deacidification, decolorization, and deodorization are typical refining processes used to enhance the characteristics of the palm oil.

Refining units in palm oil processing machine

Refining units in palm oil processing machine

7. Fractionation:

Fractionation is the final unit operation in palm oil processing, where the different components of palm oil, such as palm olein and palm stearin, are separated based on their melting points. The temperature used in this process needs to be determined according to the local environment.

The above are all palm oil processing units. Additionally, by-products generated during the process, such as palm kernel, are also processed to produce palm kernel oil, adding value to the overall palm oil industry. Henan Glory Company is a manufacturer with more than ten years of history specializing in the production and processing of palm oil and palm kernel oil press machines.In addition, we can also provide you with equipment customization services. If you need palm oil processing machines, welcome to consult us at any time.

PREV:What are the steps in making palm oil?

PREV:What are the steps in making palm oil?

NEXT:A comprehensive guide to start a palm oil business in Nigeria

NEXT:A comprehensive guide to start a palm oil business in Nigeria

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines