What are the best conditions for palm oil production?

For a palm oil producer, a high harvest of Fresh Fruit Bunches (FFB) is only the beginning. True success is measured by how much high-quality oil you can efficiently extract. The critical hours between harvest and processing—and the conditions within your palm oil production plant—are what ultimately dictate your profitability, oil extraction rate (OER), and competitive edge. This article delves into the best industrial and operational conditions for palm oil production. Master these factors, and you can directly increase your OER, control the increase of harmful Free Fatty Acids (FFA), and consistently produce premium-grade crude palm oil (CPO).

1. Harvest Fruit at Peak Ripeness

The foundation of high-quality palm oil production is laid in the plantation. Harvesting fruit too early or too late directly impacts your bottom line. Unripe fruits have lower oil content, suppressing your OER. Conversely, overripe fruits experience a rapid increase in Free Fatty Acids (FFA) due to enzymatic action. Best practice: Harvest when the bunch has an optimal number of loose fruits (typically 5-15), which signals peak ripeness and sets the stage for maximum OER and minimal oil quality degradation.

Ripe palm fruit bunches

Ripe palm fruit bunches

2. Minimize the Harvest-to-Processing Window

Once harvested fruit is cut or bruised, natural lipase enzymes activate and begin breaking down the oil into FFA. A delay results in: Elevated FFA levels that degrade oil quality, increase subsequent palm oil refining costs, and cause oil loss through fruit spoilage. Critical action: Process FFB within 24 hours of harvest (with 48 hours as an absolute maximum) to effectively halt this enzymatic degradation and protect your oil quality.

3. Implement Effective Sterilization

Sterilization is the first step in the palm oil production process and the primary defense against oil quality loss in the palm oil production plant. This high-temperature steam treatment serves three vital functions: it instantly inactivates lipase enzymes to curb FFA content rise; it softens the fruit for easier stripping from the bunch; and it pre-conditions the mesocarp for efficient oil release. Key to success: Ensure thorough and rapid steam treatment of FFBs to boost OER in palm oil production.

Palm fruit after sterilization

Palm fruit after sterilization

4. Execute Efficient Mechanical Extraction (Pressing)

The pressing station is a key link in palm oil production. This step is the core determinant of your OER. Inadequate pressure leaves valuable oil trapped in the fruit fibers, directly reducing yield. Conversely, excessive pressure can increase impurities and equipment wear. Optimal condition: Operate and maintain pressing machines to apply calibrated, consistent pressure to the digested fruit mash, ensuring maximum OER is achieved reliably.

Palm oil pressing machines

Palm oil pressing machines

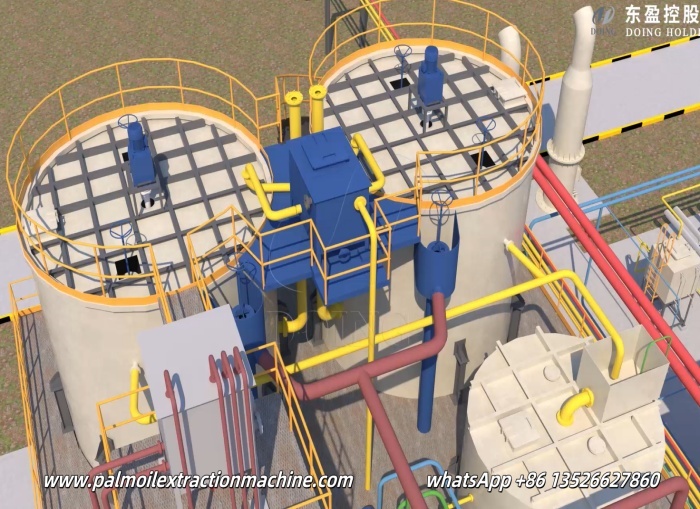

5. Ensure Precise Clarification and Purification

After palm oil extraction, maximum oil recovery depends on precise palm oil clarification. This process separates the crude oil from the pressing liquid (a mixture of oil, water, and solids). Proper clarification, controlled through optimal temperatures and efficient separation systems, ensures maximum oil is recovered from the sludge. It also enhances the initial purity of your CPO by reducing dirt and moisture content, which prevents spoilage and minimizes refining losses later.

Palm oil clarification and purification station

Palm oil clarification and purification station

6. Manage Water Quality and Usage

Water is a crucial resource in the palm oil clarification process, and its management impacts both palm oil production cost and environmental pollution. Using contaminated water introduces impurities that compromise oil quality. Proactive approach: Implement a system that uses clean water and incorporates water recycling. This significantly reduces the volume of Palm Oil Mill Effluent (POME), lowering both treatment costs and environmental impact.

Wastewater treatment

Wastewater treatment

7. Guarantee a Consistent Energy Supply

Uninterrupted palm oil production plant operation is non-negotiable for maintaining palm oil quality and throughput. Any disruption in power can lead to palm oil production process spoilage, clogging, and inconsistent oil quality. Sustainable and cost-effective solution: Utilize biomass (from empty fruit bunches and fibre) as a primary energy source. This provides a reliable and efficient power supply for sterilizers and pressing machines, turning waste into a valuable operational asset.

To summarize, by systematically mastering these industrial conditions, you transition from simply producing crude palm oil to manufacturing a premium, consistent, and highly profitable product that stands out in the global market. As a leading provider of complete palm oil production solutions, Henan Glory is committed to helping you optimize every single condition discussed above. Contact us today to learn how our technologies and expertise can be tailored to build or upgrade your palm oil production plant for peak performance and profitability.

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines