How Does a Double Screw Palm Oil Presser Work?

Have you ever wondered how to efficiently extract high-quality palm oil on a large scale? The double screw palm oil presser is central to this process, combining mechanical pressure with controlled heat to maximize oil yield while preserving quality. Let’s take a closer look at how this double screw palm oil presser reliably turns fresh palm fruit into valuable oil.

Step 1: Feeding the Palm Fruits

The process begins when fresh palm fruit is loaded into the double screw palm oil presser’s feed hopper. To improve oil release, the fruit is often gently pre-heated or steamed. This softens the pulp, ensuring smoother and more efficient extraction in the following stages.

Double screw palm oil presser’s feed hopper

Double screw palm oil presser’s feed hopper

Step 2: Pressing the Fruits

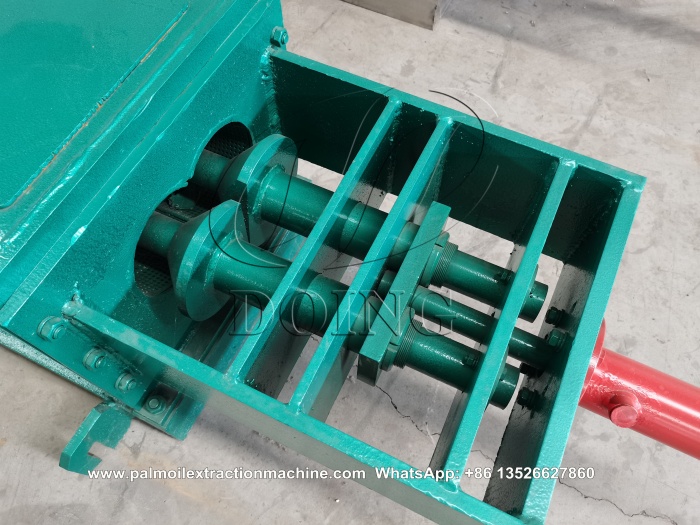

Next, inside the double screw palm oil presser, two rotating screws—also referred to as augers—work in unison. Turning in opposite directions inside a cylindrical barrel, they progressively crush the fruit. This dual-screw action thoroughly breaks down the pulp while steadily building the pressure needed to release the oil.

Two rotating screws of double screw palm oil presser

Two rotating screws of double screw palm oil presser

Step 3: Mechanical Oil Extraction

As pressure builds, oil is squeezed out from the fruit pulp. Thanks to its fluidity, the oil flows out through specially designed openings in the barrel and is channeled into a collection tank. Meanwhile, the remaining solids continue to move through the double screw palm oil presser and are discharged at the outlet. This nutrient-rich cake—known as palm oil cake—can be reused as animal feed, and uncracked kernels within it can be further processed to extract palm kernel oil.

Mechanical palm oil extraction machine

Mechanical palm oil extraction machine

Step 4: Separating Oil from Impurities

At the end of the pressing process, freshly extracted oil may still contain fine fibers, moisture, or other impurities. That’s why it is typically filtered or allowed to settle. This purification step ensures the final product is clean, stable, and ready for use or further refining.

Step 5: Temperature Control

Throughout the process, friction from the rotating screws naturally generates heat, which helps reduce oil viscosity and improve flow. Many modern double screw palm oil pressers also include integrated heating systems to maintain optimal temperatures—key to maximizing oil yield and ensuring consistent quality.

Modern double screw palm oil presser

Modern double screw palm oil presser

Whether you are operating a small local palm oil factory or a large industrial palm oil pressing plant, Henan Glory can provide you with a full range of double screw palm oil pressers to meet different production needs. Our double screw palm oil pressers are durable, easy to operate and have stable performance, helping you get more results with less effort.

If you're looking for a reliable double screw palm oil presser tailored to your specific production capacity and budget, Henan Glory will be a great partner. We can provide comprehensive support, from machine selection to after-sales service!

PREV:What are the best conditions for palm oil production?

PREV:What are the best conditions for palm oil production?

NEXT:How does a modern industrial palm oil processing plant produce palm oil?

NEXT:How does a modern industrial palm oil processing plant produce palm oil?

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines