Why palm oil processing equipment is the key to determining palm oil quality?

Palm oil, a staple commodity in the global food and cosmetics industries, owes its quality not only to the care taken during palm trees cultivation but also to the sophistication of palm oil processing equipment used in its production. The efficiency and effectiveness of the palm oil processing equipment directly impact the final product's characteristics, including color, flavor, aroma, and nutritional content. In this article, we will delve into the reasons why palm oil processing equipment is the key to determining palm oil quality.

Firstly, one key aspect of palm oil processing equipment is the extraction method used. Traditional methods, such as the use of manual presses or rudimentary machinery, may result in lower-quality palm oil due to inadequate extraction of the oil from the palm fruits. Modern palm oil processing equipment, such as hydraulic presses or screw presses, can extract a higher percentage of oil from the palm fruits, leading to a higher-quality palm oil.

Two kinds of screw palm oil press equipment

Two kinds of screw palm oil press equipment

Secondly, the quality of the palm oil processing equipment can affect the temperature and processing time during the palm oil processing process. Maintaining optimal processing conditions is essential to preserve the palm oil's natural properties and prevent degradation. High-quality palm oil processing equipment can control these factors more effectively, resulting in a superior palm oil.

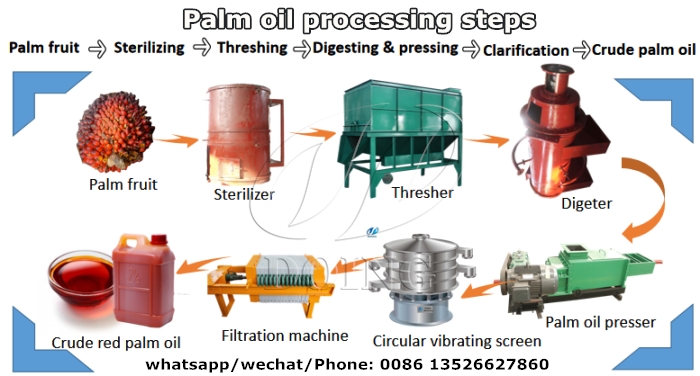

Complete palm oil processing equipment

Complete palm oil processing equipment

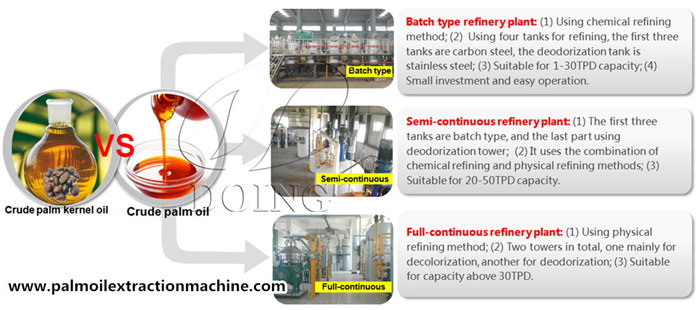

Furthermore, palm oil refining process is an essential step in palm oil processing process where the palm oil undergoes a series of treatments including degumming, deacidification, decolorization and deodorization. Palm oil refining equipment precisely controls the application of heat, pressure, and sometimes chemicals to remove unwanted substances. The level of refinement directly correlates with the palm oil's color, taste, and stability, thus affecting its market value and usability in various products.

Three kinds of palm oil refining equipment

Three kinds of palm oil refining equipment

In addition, the cleanliness and maintenance of the palm oil processing equipment are critical in ensuring the quality of the palm oil. Contaminants or residues from previous batches can negatively impact the palm oil's quality and shelf life. Regular cleaning and proper maintenance of the palm oil processing equipment are essential to prevent contamination and ensure consistent palm oil quality.

In conclusion, palm oil processing equipment is indeed the key to determining palm oil quality. Investing in high-quality, modern equipment, maintaining optimal processing conditions, and ensuring proper equipment hygiene are essential steps in producing high-quality palm oil with desirable characteristics. If you want to obtain palm oil processing equipment that can produce high-quality palm oil, Henan Doing Company will be a good choice for you. We are a professional manufacturer of edible oil processing equipment and can provide you with one-on-one guidance services.

PREV:What is a comprehensive guide to setting up the best palm oil refinery plant?

PREV:What is a comprehensive guide to setting up the best palm oil refinery plant?

NEXT:What are the mill methods of palm nut oil? What are their different?

NEXT:What are the mill methods of palm nut oil? What are their different?

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines