Why setting up a palm oil mill is worth investing in?

Are you looking for an industrial investment opportunity with sustained market demand, diverse applications and stable returns? Setting up a palm oil mill may be an option worth investing in. With the growing global demand for vegetable oils, palm oil, with its unique advantages, has become an indispensable ingredient in a variety of industries, including food, cosmetics and biofuels. Next, I will sort out the following reasons for you from the perspective of actual investment:

First, palm oil is one of the most widely consumed vegetable oils in the world. It's not only widely used in cooking, fast food and baking, but it's also a key ingredient in cosmetics, soaps, detergents and even biodiesel. Furthermore, due to its affordability, palm oil is particularly in high demand in Asia, Africa and the West. This means that once a palm oil mill is set up and palm oil production begins, you'll be tapping into a large and continuously growing market.

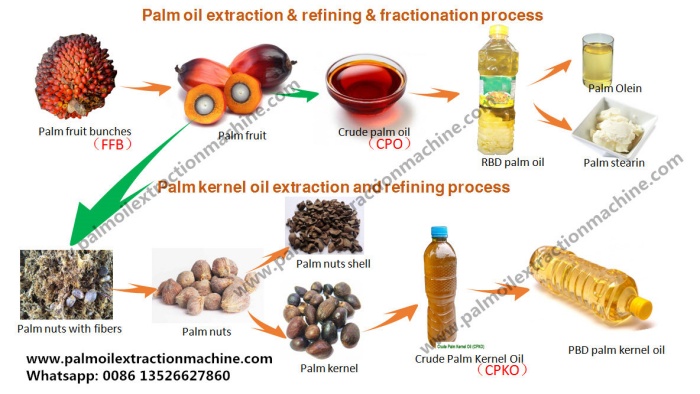

Palm oil products

Palm oil products

Secondly, compared to other oil crops like soybeans and rapeseed, palm oil trees produce more oil per hectare—approximately four to ten times more oil per hectare than a comparable area planted with other crops. This means you can achieve more output from the same amount of land, and this efficiency advantage translates directly into profit. Once the plantation reaches maturity, low maintenance costs, a long lifespan (up to 25-30 years) and stable returns that can position you for a dominant position in the market.

Palm tree plantation

Palm tree plantation

Then, it's worth noting that many countries around the world are promoting renewable energy development, and palm oil is a key feedstock for biodiesel. Many countries are adopting biofuels as part of their strategies to reduce reliance on fossil fuels and carbon emissions. Governments around the world are providing subsidies and policy support for biofuel production, which provides palm oil mills with new output channels and profit growth opportunities.

Next, you need to understand that in addition to the main product—palm oil, palm oil mills can also extract palm kernel oil (widely used in high-end foods, cosmetics and soaps) during processing. It can also convert waste products, such as empty fruit bunches and fiber, into biomass fuel for sale. This not only effectively reduces your energy costs but also helps increase your revenue stream.

Palm kernel oil—a by-product of palm processing

Palm kernel oil—a by-product of palm processing

Of course, the construction and operation of a palm oil mill also creates numerous local employment opportunities, from palm tree planting, palm fruit harvesting and transportation, to palm oil processing and production management, helping to boost the regional economic cycle. It also makes it easier to obtain local policy support and reduce investment risks. Besides, palm oil production is often integrated with local agricultural activities, allowing farmers to provide raw materials, thus forming a mutually beneficial ecosystem.

To sum up, investing in setting up a palm oil mill not only relies on a global demand market, but also has multiple advantages such as high efficiency, multiple product chains and policy support. If you have an investment plan to setting up a palm oil mill, please contact the Henan Glory team. We will provide you with all-round support from planning to implementation with our professional solutions and rich experience!

PREV:What Kind of Engineering Service Can Henan Glory Offer in Palm Oil Processing Project?

PREV:What Kind of Engineering Service Can Henan Glory Offer in Palm Oil Processing Project?

NEXT:Demystifying the crude palm oil clarification process in large-scale mills

NEXT:Demystifying the crude palm oil clarification process in large-scale mills

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines