Dry fractionation of RBD palm oil

Factory direct sale contact number

Dry Fractionation of RBD Palm Oil

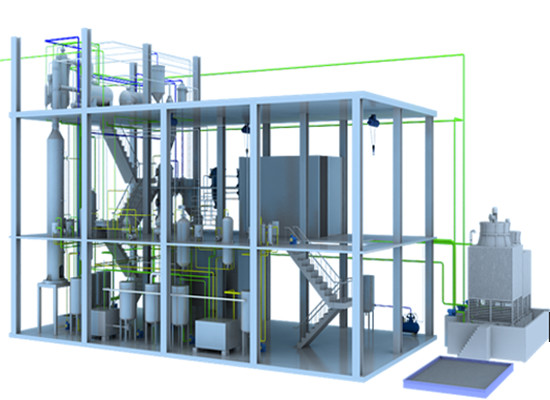

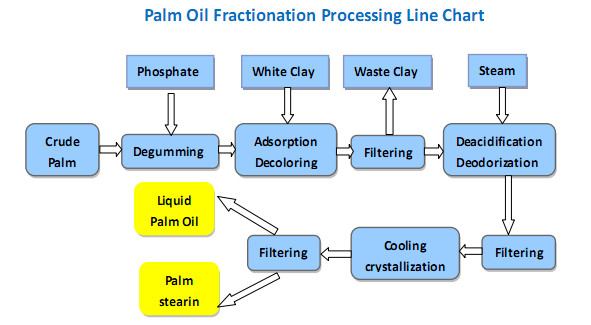

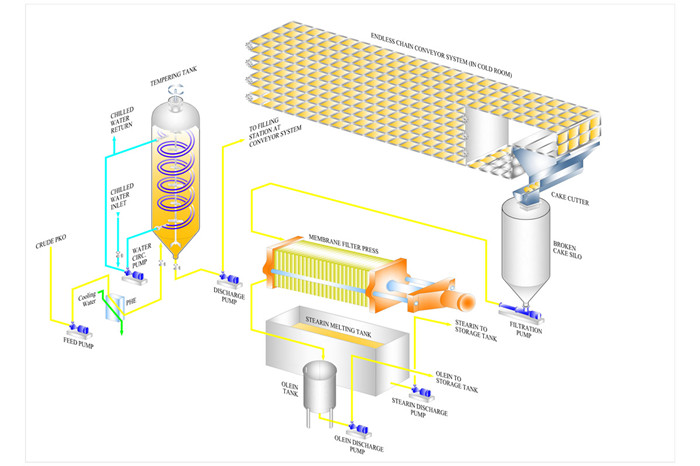

Dry fractionation of RBD palm Oil also called dry fractionation of rbd(Refined, Bleached, and Deodorized) palm oil. The Henan Doing dry fractionation process is designed to separate palm oil into two fractions, Olein and Stearin, without the addition of chemicals or solvents. Same palm oil fractionation plant can be used for producing super olein and palm mid fraction of varying cloud point and melting point.

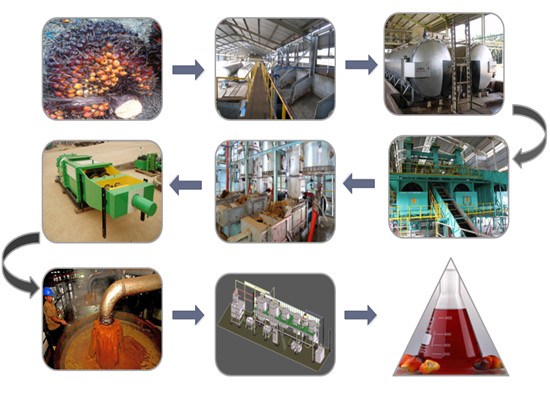

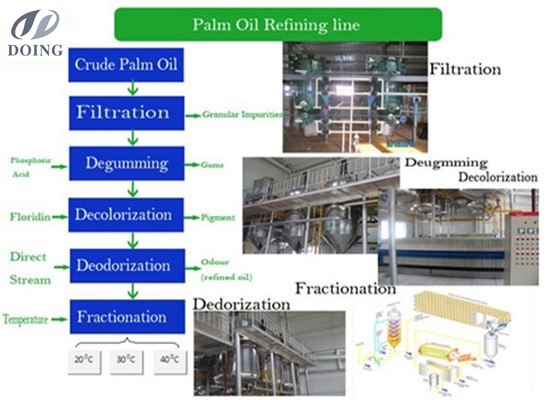

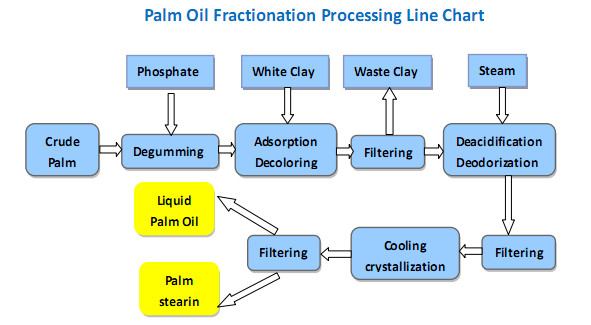

Palm oil fractionation process

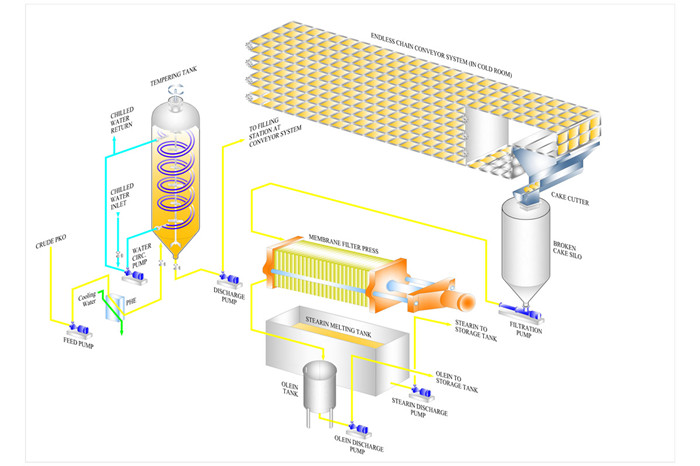

The dry fractionation process includes :

• Preheating the feed stock to give a homogenous mass with nil solids.

• Crystallisation under preset controlled conditions of temperature & agitation to form stable, uniform sized filterable crystals.

• Filtering on membrane press filter (or Rotary Drum Vacuum filter) to separate the solid/liquid fractions.

Dry fractionation

Main Features & Advantages of Dry Fractionation of RBD Palm Oil

• Combines all operations, and monitors from a fully automated centralized control station.

• Easy to operate, requires minimum supervision.

• Good flexibility. Wide range of process applications possible.

• Feedstock can be crude, semi refined or fully refined palm oil.

• Suitable for both single or double fractionation.

• Minimum operating costs.

- Low utility consumption

- Low maintenance costs

- No oil losses

- No pollution problem

• Product quality.

- Good crystallization repeatability, yielding consistent product quality

- High olein yields

- Low olein cloud point, with improved cold stability, Cloud point as low as 2 °C with iodine value of

65.0 can be obtained

Dry fractionation of RBD palm Oil also called dry fractionation of rbd(Refined, Bleached, and Deodorized) palm oil. The Henan Doing dry fractionation process is designed to separate palm oil into two fractions, Olein and Stearin, without the addition of chemicals or solvents. Same palm oil fractionation plant can be used for producing super olein and palm mid fraction of varying cloud point and melting point.

Palm oil fractionation process

The dry fractionation process includes :

• Preheating the feed stock to give a homogenous mass with nil solids.

• Crystallisation under preset controlled conditions of temperature & agitation to form stable, uniform sized filterable crystals.

• Filtering on membrane press filter (or Rotary Drum Vacuum filter) to separate the solid/liquid fractions.

Dry fractionation

• Combines all operations, and monitors from a fully automated centralized control station.

• Easy to operate, requires minimum supervision.

• Good flexibility. Wide range of process applications possible.

• Feedstock can be crude, semi refined or fully refined palm oil.

• Suitable for both single or double fractionation.

• Minimum operating costs.

- Low utility consumption

- Low maintenance costs

- No oil losses

- No pollution problem

• Product quality.

- Good crystallization repeatability, yielding consistent product quality

- High olein yields

- Low olein cloud point, with improved cold stability, Cloud point as low as 2 °C with iodine value of

65.0 can be obtained

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

Palm oil refinery

Products

palm oil mill plant projects

Palm Oil Extraction FAQ

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines

recommend products