1tpd stainless steel electric heating palm oil refinery plant

1tpd stainless steel electric heating palm oil refinery plant belongs to micro palm oil refining machine, it mainly suitable for small scale cooking oil factory. The whole electric heating palm oil refinery plant has four tanks: two refinery tank, one decolorization tank, and one deodorization tank. The material of all tanks are made by stainless steel.

Specification information of electric heating palm oil refinery plant:

| Material: | stainless steel |

| Daily processing capacity: | 1 ton per day(1000kg per day) |

| Suitable object: | all kinds of vegetable oil, all kinds of animal oil, all kinds of cooking oil,and so on. |

| Heat source: | electric heating energy saving and environmental protection type (frequency conversion, automatic temperature control) |

| Voltage: | 220-440V, 3 phase |

| After-sales service: | Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support, Engineers available to service machinery overseas. |

The function of these four tanks are as below:

1.Two refinery tanks: The function of refinery tanks is used to remove the gum and free fatty acid (FFA) in the crude palm oil through acid refining, alkali refining and water washing methods.

2.Decolorization tank: The function of decolorization tank is to remove the color pigments contained in oils. Because the crude oil is dark color, decolorization will make the oil become clear and light color by using white soil adsorption method.

3.Deodorization tank: The function of this deodorization tank is to remove disagreeable flavor and odors that are naturally present or created during refining processing under high temperature.

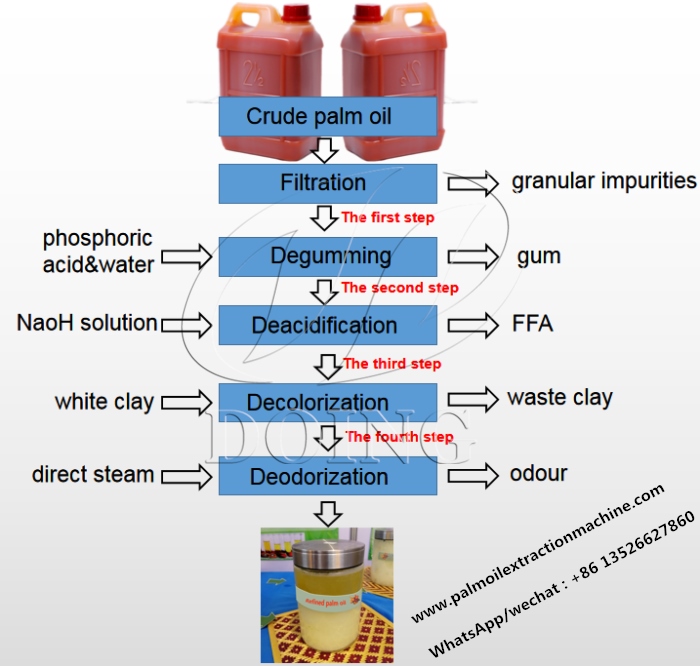

Refining process of 1tpd stainless steel electric heating palm oil refinery plant is as follows:

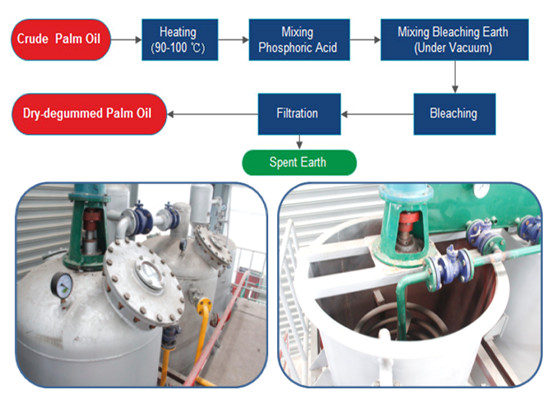

Palm oil refining process flow chart

Palm oil refining process flow chart

The detailed refining steps of 1tpd stainless steel electric heating palm oil refinery plant is as below:

●Step 1: The crude oil will be filled in the first tank by pump, and then add the phosphoric acid and alkali, the gum and soapstock will settle in the bottom of refinery tank. After standing for a period of time, we can open the valve to discharge the soapstock.

The function of two refinery tanks is same, they work together to match the behind refining processing.

●Step 2: After degumming and deacidification process, the refined oil will be transported to decolorization tank for further processing.

During deolorization process, we use the white clay to absorb the color, and then use the leaf filter to separate the waste clay and decolorized cooking oil. This filter is automatic, you don't need to discharge the waste clay by manual.

●Step 3: The final processing step is deodorization, this part mainly adopts the steam distillation principle to remove the bad smells in decolorized cooking oil, this operation is carried out under high temperature and high vacuum conditions. Due to the temperature in this step is more than 200 degree, the material of deodorization tank must be stainless steel.

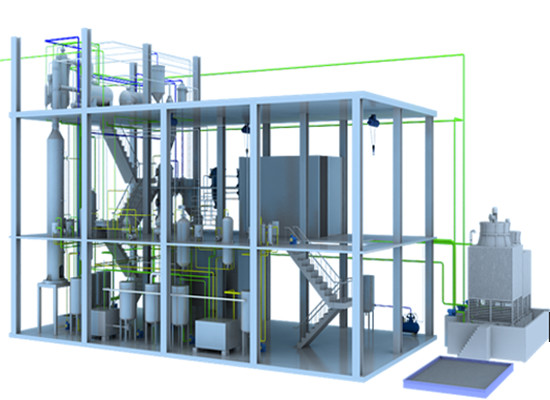

Small scale palm oil refinery plant

Small scale palm oil refinery plant

Above are the related information of the 1tpd stainless steel electric heating palm oil refinery plant, more specification information about this machine, welcome to contact Henan Glory Company.

As a professional manufacturer of cooking oil refining machine, Glory Company not only supply the high quality electric heating palm oil refinery plant, but also supply the careful and considerate after-sales service. Our company can provide you with the most professional advice from product consultation, to recommendation of suitable equipment, to transportation, installation, commissioning and normal production of equipment. Welcome to visit Henan Glory Company to choose suitable palm oil refinery plant.

PREV:1-10tpd batch type palm oil refining machine

PREV:1-10tpd batch type palm oil refining machine

NEXT:Batch type palm oil refinery plant and continuous palm oil refinery plant

NEXT:Batch type palm oil refinery plant and continuous palm oil refinery plant

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines