1-10tpd batch type palm oil refining machine

Generally speaking, after we press palm fruit, we will get the crude palm oil. Due to there are still some impurities such as phospholipids, FFA, pigment, odor, etc. in the crude oil, and these impurities will directly change the oil’s color, smell, taste, transparency, stability degree and nutrition, which not only affect the price of edible oil, but also make the oil easy to deteriorate when storing. So we need to use palm oil refining machine to refine the crude palm oil to get high quality cooking oil.

Small scale palm oil refining machine

Small scale palm oil refining machine

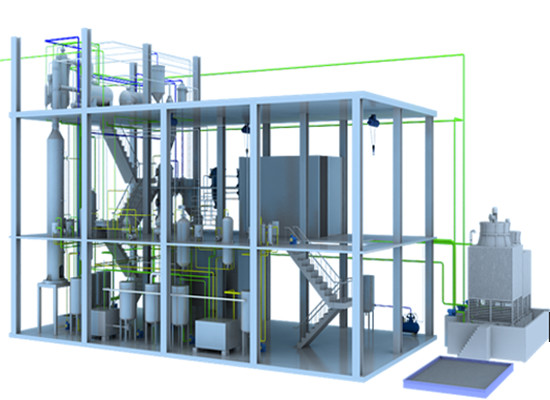

Depending on the different of customer's requirements and production scale, there are three different types of palm oil refining machine can be chose to produce cooking oil, they are: batch type palm oil refining machine, semi-continuous palm oil refining machine and fully continuous palm oil refining machine. Today we mainly introduce 1-10tpd batch type palm oil refining machine. (Related post: What is the price of palm oil refining machine?)

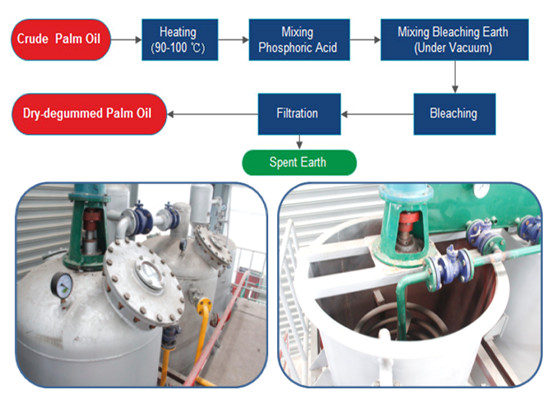

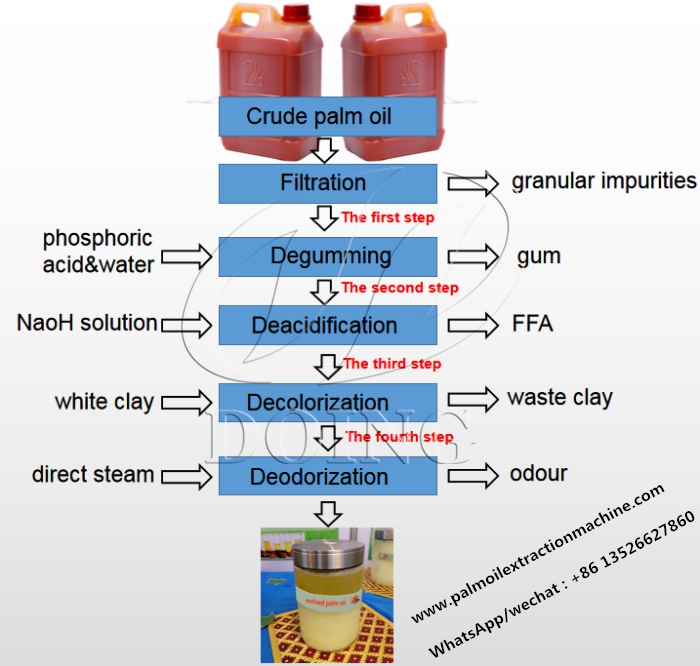

As with continuous palm oil refining machine, 1-10tpd batch type palm oil refining machine also includes four mainly processes: degumming, deacidification, decolorization, deodorization. Here, Henan Glory Oils & Fats Engineering Co., Ltd will take you learn about each refining process of batch type palm oil refining machine.

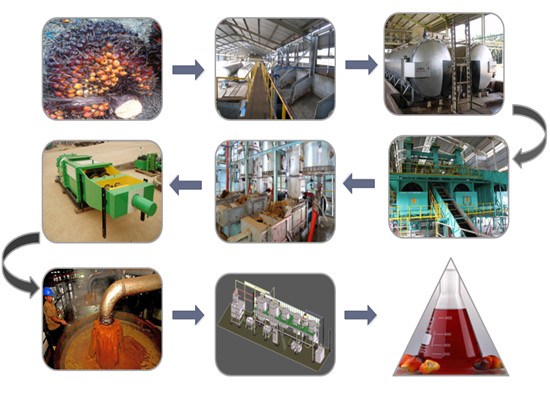

Palm oil refining process flow chart:

Palm oil refining process flow chart

Palm oil refining process flow chart

Degumming section: There are some phospholipid, gum, and protein, they can be dissolved into oil when there is no water, but once there is water in oil, these impurity can be dissolved into water. So, in degumming section, we usually use the hot water to wash crude oil for two-three times to make gold phospholipid condenses and reduces colloid, To reach the better dugumming effect, we usually need wait several hours,then open the below valve release the gums.

Deacidification section: During this section, The most widely used method is adding some chemical materials (alkali liquor) to remove the acid materials. And then open the below valve release the soapstock.

If the content of FFA in crude oil is high, we will lost much oil and get much soapstock. But if the content of FFA in crude palm oil is low, we will get more oil and less soapstock.

Decolorization section: Decolorization is carried out by the obsorption function of white clay, this step usually need 25mins, temperature requirements around 105-110 Celsius.

Deodorization section: This step have high temperature requirement , around 260 Celsius, based on very high temperature, steam can remove oxidation number, aldehydes, and ketones in crude oil. In addition, some of acid and bad smell also can be taken off in this step..

After the above four step, we will get the RBD palm oil, if you want to further process RBD palm oil to get palm olein and stearine, we can also supply the palm oil fractionation plant.

Photos of batch type palm oil refining machine:

Palm oil refining equipment with various processing capacity

Palm oil refining equipment with various processing capacity

Do you want to set up a palm oil refinery plant? Welcome to contact Henan Glory Oils & Fats Engineering Co., Ltd, we will customize the palm oil refinery process and solution for each of customer depending on their specific situation and needs.

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

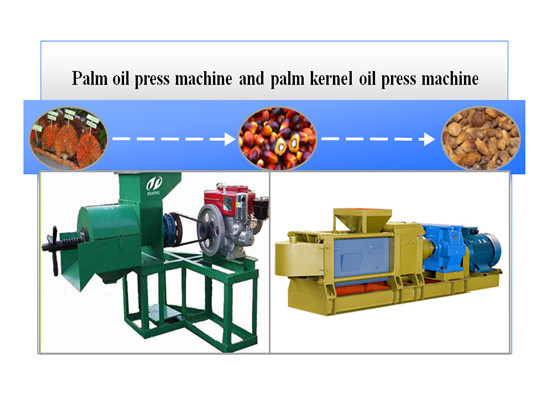

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

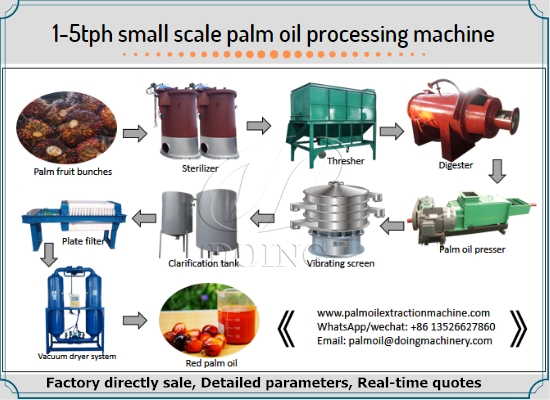

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines