From Palm Oil to PKO Profits: Essential Equipment for Mill Expansion

Expanding a palm oil mill to include Palm Kernel Oil (PKO) production can significantly increase profitability, as PKO is a valuable by-product with a wide range of applications in the food, cosmetics, and bio-fuel industries. The process involves extracting oil from the palm kernel (the kernel inside the fruit), which requires additional processing steps and specialized equipment. Henan Glory Company will introduce you to the essential equipment needed to expand your mill to produce PKO, as well as the considerations for improving efficiency and profitability.

I. Essential Equipment for Palm Kernel Oil (PKO) Production

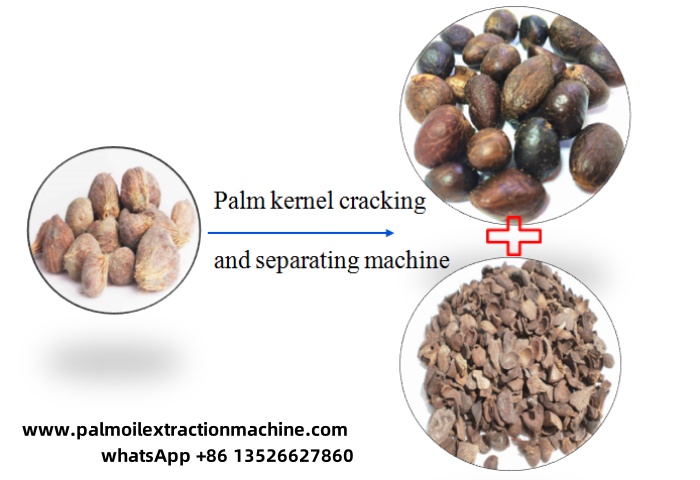

1. Palm Kernel Cracking and Separation Equipment

Palm Kernel Cracker: This machine is designed to break the hard shell of the palm nut to release the kernel inside. Depending on the scale of production, you may choose between manual or automated machines.

Nut and Shell Separator: After cracking, the kernels need to be separated from the shell. This is typically done using an air separator or a vibration separator. The separation of kernels from shells is essential to ensure the quality of the oil extracted later.

Palm kernel cracker and separator equipment

Palm kernel cracker and separator equipment

2. Palm Kernel Pretreatment Equipment

Palm Kernel Crusher: The palm kernels must be crushed to reduce their size, making it easier to extract oil.

Palm Kernel Conditioning: This involves heating and conditioning the kernels to improve oil yield. Conditioning machines (such as roaster or softening cooker) are used to soften the kernels before pressing, regulating temperature and moisture. According to the characteristics of the oil seeds, the oil seed can be adjusted to different temperatures and can be used for cold pressing and hot pressing.

Palm kernel crushing equipment

Palm kernel crushing equipment

3. Palm Kernel Oil Extraction Equipment

Hydraulic Presser: The machine uses the principle of liquid transmission pressure to squeeze the oil seed and extract the oil. The machine has a simple structure, easy operation and low power consumption. It is suitable for small oil plants with a large variety of oils but small quantities, and for processing scattered oil seeds.

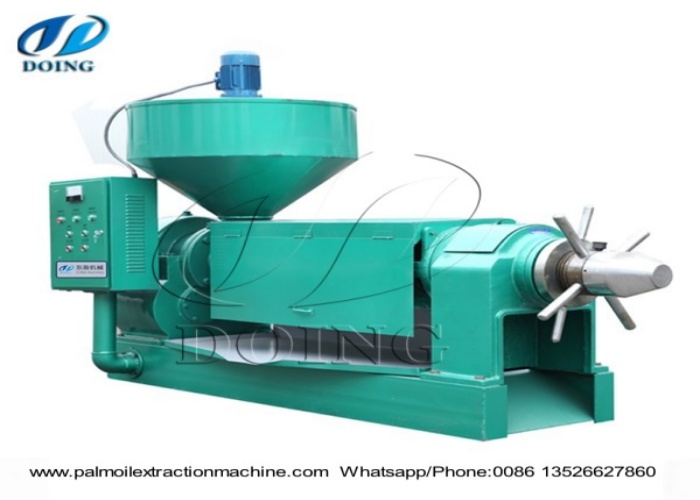

Screw Presser: Some mills may use a screw press, which is particularly useful for large-scale operations and produces a high yield of oil with lower energy consumption. Our company, Henan Glory, has upgraded our palm kernel oil screw press machine, using a screw made of a special material, which improves the pressing effect and lasts longer.

Palm kernel oil screw press equipment

Palm kernel oil screw press equipment

4. Palm Kernel Oil Filtration Equipment

Plate Filter: This is an essential tool for further cleaning the extracted PKO. The filter removes solid impurities and helps in separating the oil from fine particles.

Palm kernel oil plate filter

Palm kernel oil plate filter

II. Key Considerations for Mill Expansion to Include PKO Production

1. Efficiency and Automation

Expanding your mill to process PKO requires careful consideration of the scalability of your equipment. Automated systems can improve efficiency by reducing labor costs, improving consistency in oil quality, and increasing production output. Consider automating stages such as cracking, separation, and pressing to optimize your operations.

2. Energy Consumption and Optimization

Palm oil extraction is energy-intensive. Consider installing energy-efficient equipment or renewable energy sources, such as solar power or heat generated by burning factory waste, to reduce energy costs.

3. Waste Management

Processing palm kernels generates by-products such as shells, fiber, and cake. Efficient waste management strategies can turn these by-products into valuable products:

Palm Kernel Cake: The remaining solids after oil extraction can be sold as animal feed or fertilizer.

Palm Kernel Shells: Can be used as fuel to generate energy or be sold as biomass fuel.

Palm Fiber: Can be used in the production of fiberboard, or as a fuel source.

By adopting a circular economy model and reusing waste materials, the profitability and sustainability of the factory can be further improved.

The composition of palm nut

The composition of palm nut

III. Profitability and Return on Investment

The addition of PKO production can significantly increase the profitability of your palm oil mill. However, it is essential to understand the cost structure of adding PKO production:

Initial Investment: The cost of expanding to include PKO production can be high due to the additional equipment, labor, and operational requirements.

Operating Costs: These include raw materials (palm kernels), energy, labor, and maintenance.

Revenue Potential: The PKO market has strong growth potential, especially in sectors like food and cosmetics. As the price of palm kernel oil tends to be higher than crude palm oil, this diversification can provide higher margins.

In conclusion, expanding a palm oil mill to produce PKO involves a significant investment in specialized equipment and infrastructure. However, with the right machinery, efficient operations, and solid marketing strategies, it can be a profitable venture. By extracting both palm oil and palm kernel oil, your mill can diversify its revenue streams, optimize its resources, and tap into new markets, ensuring long-term success and profitability.

Whether you already have a palm kernel oil production line, are planning to expand it, or are interested in a single equipment for palm kernel oil production, Henan Glory can customize the most suitable and optimal solution for you. Feel free to contact us with any of your needs!

PREV:Optimize your palm oil extraction line: fractionation process & equipment explained

PREV:Optimize your palm oil extraction line: fractionation process & equipment explained

NEXT:How does palm oil extraction plant work and what steps do you need to follow to extract it?

NEXT:How does palm oil extraction plant work and what steps do you need to follow to extract it?

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines