How many types of palm oil refinery plant does Glory Company have for sale?

Now more and more people choose to do refined palm oil business and expand refineries on the basis of their existing crude palm oil pressing plant , or buy crude oil from crude palm oil suppliers for refining. Henan Glory company has done palm oil refinery equipment more than 11 years, The following will introduce the different type palm oil refinery machine to you from different aspects.

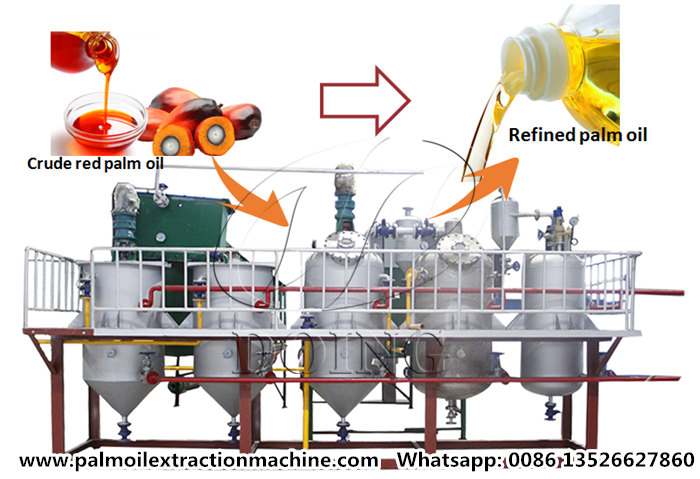

Palm oil refinery equipment

Palm oil refinery equipment

1. According to different heating methods, it can be divided into electric heating type and refining, and heat conduction oil type.

Electric heating type refining

Electric heating type refining

Electric heating refining is suitable for 0.5-2tpd capacity. The feature is that resistance wire is used to heat the crude oil, which requires less investment, but higher voltage stability and consumes more power.

Heating conduction oil type is suitable for processing more than 1 ton. Using heat conduction oil to heat crude oil requires a heat conduction oil furnace, but it is more economical in the long run.

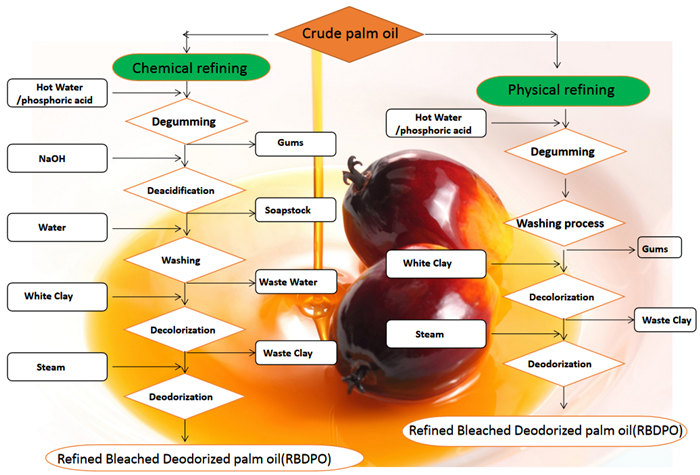

2. Classified by refining process can be divided into physical refining and chemical refining.

physical refining and chemical refining process

physical refining and chemical refining process

Generally speaking, physical refining and chemical refining can be distinguished according to whether alkali deacidification is added or not.

Chemical refining: it is general type, which is suitable for any kinds of oilseeds.

Physical refining: it is more practical for oils with less gum content and high acid value, such as palm oil, palm kernel oil and coconut oil, etc.

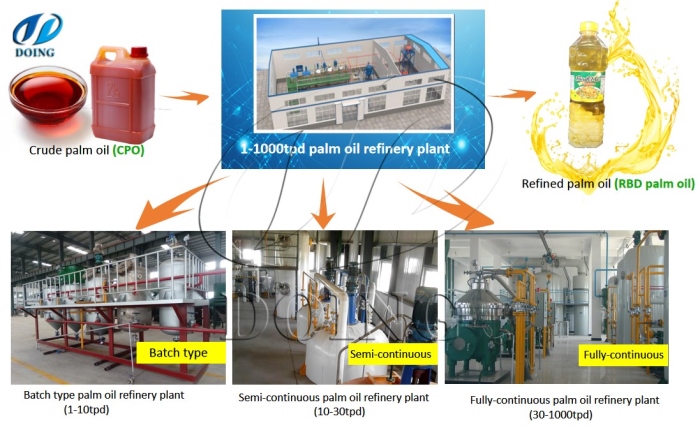

3. According to the degree of automation, it can be divided into batch refining, semi-continuous refining and full continuous refining.

Batch refining, semi-continuous refining and full continuous refining plant

Batch refining, semi-continuous refining and full continuous refining plant

Refining steps are divided into degumming, deacidification, decolorization, deodorization.

Batch refining: generally used for ≤20TPD refining capacity. The advantages of batch refinery are simple and flexible equipment operation, less investment, suitable for frequent replacement of various oils .Then the disadvantages are low oil yield, large loss, low work efficiency, unstable product quality.

Semi-continuous refining: generally used for 5-30TPD refining capacity. Under normal circumstances, the degumming and decolorization section is intermittent production; the deacidification and deodorization section adopts the deodorization tower process for continuous production to achieve continuous refining, high efficiency, energy saving, economy, and high additional output value.

Full continuous refining: generally used for ≥ 30TPD refining capacity. The alkali refining section is equipped with a disc centrifuge, replacing the natural sedimentation of the refining pot to separate the saponins, and all sections of the full continuous refining are continuous production and uninterrupted. The advantage of this design is that the production consumption is small, the oil loss is low, and the refining oil quality is more stable.

Through the above introduction, is everyone very clear about the type of refinery machine? Our engineers have more than ten years of project experience in palm oil refining, the technology is very mature, and the quality of the refined oil obtained meets the national standards. If you are interested in our refinery business, please feel free to contact us!

Leave A Message

If you want to know more information about How many types of palm oil refinery plant does Glory Company have for sale? . pls kindly leave your phone number, We will back to you ASAP once we got your message.

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

How to set up a 5t/h to 10t/h automated palm oil and kernel oil processing line in Nigeria?

How to set up a 5t/h to 10t/h automated palm oil and kernel oil processing line in Nigeria?

-

Detailed analysis of palm kernel cracking and separating machine

Detailed analysis of palm kernel cracking and separating machine

-

What are the specifications and capacity of Henan Glory's palm kernel cracker and shell separator?

What are the specifications and capacity of Henan Glory's palm kernel cracker and shell separator?

-

Introduction of Henan Glory's different palm fruit sterilization equipment

Introduction of Henan Glory's different palm fruit sterilization equipment