What is the Sludge Treatment Process in a Large Palm Oil Mill?

In a large palm oil mill, true efficiency is achieved when nothing is wasted. An advanced sludge treatment process is the hallmark of a top palm oil mill, creating a closed-loop system that continuously recovers valuable oil. This isn't merely about waste management; it also delivers a clear and compelling return on investment by minimizing loss and boosting your final yield.

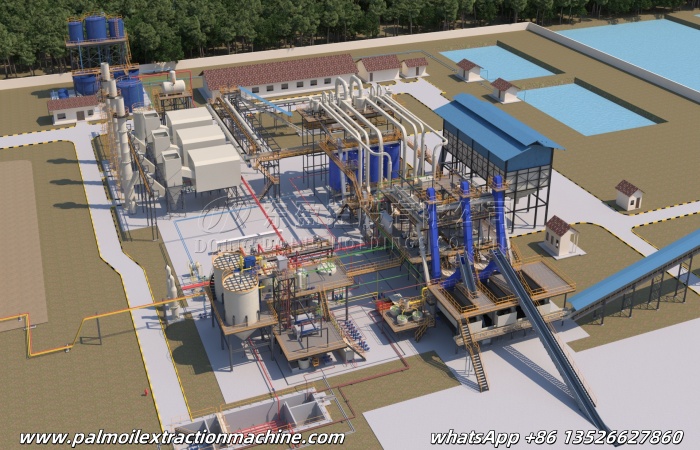

Large palm oil mill

Large palm oil mill

With extensive experience in the design and implementation of palm oil processing systems, Henan Glory Oils & Fats Engineering Co., Ltd. has perfected an efficient sludge treatment process. Next, we will introduce you to the specific sludge treatment process in large palm oil mills.

The sludge treatment journey begins after the palm fruit is digested and pressed. The resulting crude palm oil flows through a series of oil clarification tanks. The clear oil in the oil clarification tanks first passes through a vibrating screen to remove some impurities before entering large vertical clarification tanks. Finally, the sludge at the bottom of the oil clarification tanks and large vertical oil clarification tanks is regularly transported to a dedicated sludge oil pit for recycling.

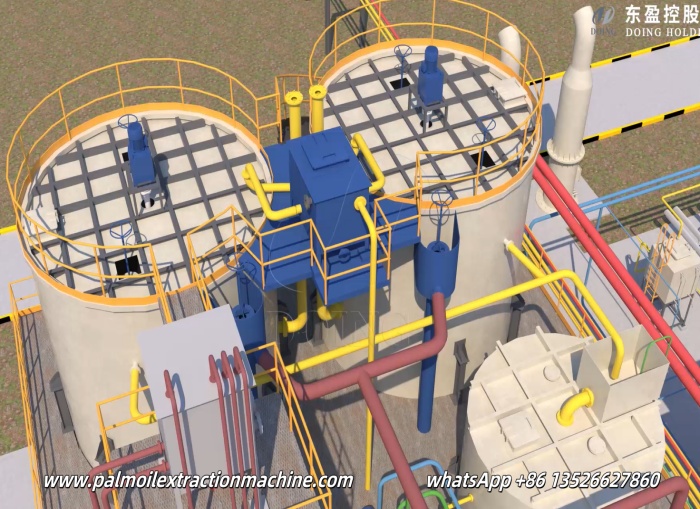

Large vertical oil clarification tanks

Large vertical oil clarification tanks

Additionally, the sludge oil from the large vertical oil clarification tanks will be collected in the sludge oil tank and then heated with direct steam, which helps increase its fluidity for subsequent processing. The heated sludge oil enters the first-stage oil cyclone, where hot water is added to separate the clean oil. The remaining sludge oil enters the desanding tank, where it is further separated by bottom steam heating before entering the second-stage oil cyclone for further separation. The mixture is then transferred to a three-phase decanter centrifuge. The oil, water, and sludge produced by the three-phase decanter centrifuge are collected in a mixing tank below, diluted with water, and then recycled into the sludge oil pit.

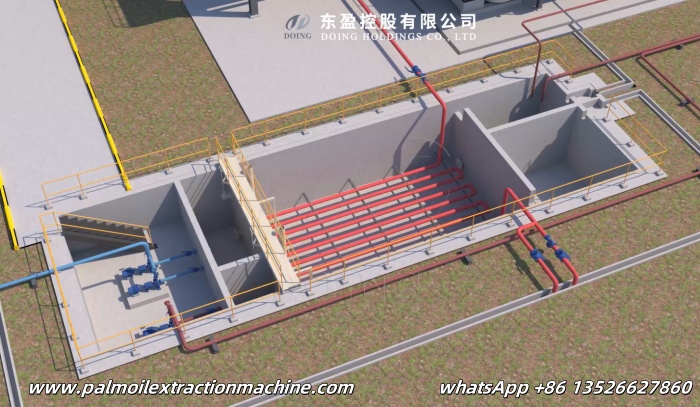

This leads to the final recovery stage. The sludge oil pit in a large palm oil mill has two sedimentation tanks. The sludge oil overflows into a large tank equipped with a heating coil. The upper layer is used to discharge the final effluent, while the lower layer is used to discharge the sludge oil. The final sludge oil is then pumped into the oil clarification tanks for recirculation. This continuous cycle minimizes oil loss.

The sludge oil pit in a large palm oil mill

The sludge oil pit in a large palm oil mill

In conclusion, by implementing a closed-loop process for sludge treatment, you can not only minimize oil losses and maximize yields, but also create a more sustainable and efficient large palm oil mill. If you are looking to enhance the efficiency and profitability of your large palm oil mill, our sludge treatment process is a proven solution. Please feel free to contact us for a detailed consultation.

PREV:How does a modern industrial palm oil processing plant produce palm oil?

PREV:How does a modern industrial palm oil processing plant produce palm oil?

NEXT:The Value for You to Choose a Palm Oil Processing Machine Supplier with Warehouse in Nigeria

NEXT:The Value for You to Choose a Palm Oil Processing Machine Supplier with Warehouse in Nigeria

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines