What are the factors that affect the price of palm oil production plants?

Building or upgrading a palm oil production plant (POPP) requires significant capital investment, and costs can fluctuate widely. Understanding the factors that affect the price of palm oil production plants is crucial to planning profitable and efficient operations. Here's a breakdown of the main factors:

1. Production Capacity

One of the most significant factors affecting the price is the palm oil production plant’s processing capacity. A small-scale palm oil production plant designed to handle 1-5 tons per hour will cost significantly less than a large-scale industrial palm oil production plant that processes over 30 tons per hour. Higher processing capacity requires more robust machinery and larger infrastructure, which drives up the price of palm oil production plants.

1-5 Tons per hour palm oil production plant

1-5 Tons per hour palm oil production plant

2. Equipment Configuration

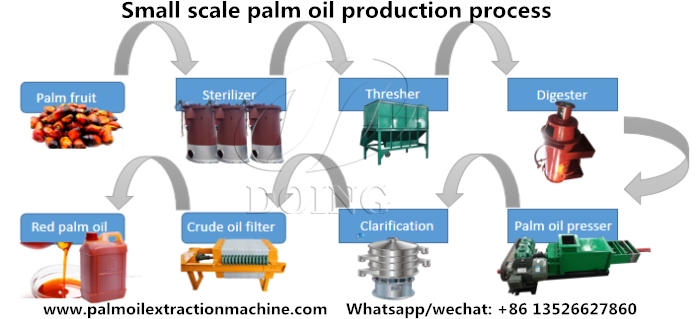

The price of palm oil production plants also depends on whether the palm oil production plants includes only the palm oil pressing section or a full palm oil refining and fractionation line. The cost of a complete set of equipment (typically including palm oil sterilization equipment, palm oil threshing equipment, palm oil digesting equipment, palm oil pressing equipment, palm oil clarification and refining equipment) will obviously be higher than a basic crude palm oil production system.

Complete set of palm oil production equipment

Complete set of palm oil production equipment

3. Automation Level

Modern palm oil production plants often feature semi-automatic or fully automatic systems. While automatic systems reduce labor and improve efficiency, they come with higher upfront costs due to advanced control panels and sensor integration.

4. Quality and Material of Equipment

The quality of materials used in palm oil production equipment—such as stainless steel for food-grade components—affects the palm oil production plant’s durability, safety and compliance with international standards. Premium materials and precision manufacturing increase the investment cost but ensure longer service life and lower maintenance.

5. Installation and After-Sales Support

Some suppliers, such as Henan Glory Company, can offer turnkey services that include equipment installation, training and after-sales maintenance. These value-added services can influence the overall price of palm oil production plants, but they ensure smoother startup and better long-term operation.

Equipment installation site

Equipment installation site

6. Transportation and Customization

Shipping logistics, import duties and any customization (e.g., layout design tailored to your palm oil production plant space) also contribute to the price.

In short, there are many factors that influence the price of a palm oil production plant. If you're considering building your own palm oil production plant, contact Henan Glory Company(with branch and overseas warehouse in Nigeria) for tailored solutions that match your production goals and budget. Our expert team is ready to help you design, install and optimize your palm oil production line for maximum efficiency and profitability.

PREV:Demystifying the crude palm oil clarification process in large-scale mills

PREV:Demystifying the crude palm oil clarification process in large-scale mills

NEXT:Continuous vs. Batch Palm Oil Refining Machines Which is Best for Your Plant

NEXT:Continuous vs. Batch Palm Oil Refining Machines Which is Best for Your Plant

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines