From palm oil to kernel oil: turnkey solutions for expanding your processing plant

Expanding your palm oil processing plant to include palm kernel oil production can be a great move to increase your palm oil processing plant’s capacity and diversify your product offerings. Here's a step-by-step guide turnkey solutions for expanding your palm oil processing plant:

Step1. Feasibility Study and Market Research

(1) Demand Analysis: Research the market demand for palm kernel oil, which is used in cosmetics, food and industrial applications. Understanding the demand and competition will guide your decision.

(2) Cost-Benefit Analysis: Evaluate the investment required for palm oil processing plant expansion, including new palm kernel oil processing equipment, additional workforce and training costs.

Step2. Plant Layout and Design

(1) Infrastructure Modifications: Adjust your existing palm oil processing plant layout to accommodate the new palm kernel oil processing line. This may include creating space for additional palm kernel oil processing equipment and storage.

(2) Energy Efficiency: Ensure your palm oil processing plant uses energy efficiently by upgrading power systems or optimizing the palm kernel oil processing process.

Step3. Supply Chain and Raw Material Sourcing

(1) Palm Kernel Sourcing: Establish reliable sources for palm kernels, either from palm oil processing if you are not already sourcing directly. Work with reliable plantations to obtain high quality palm kernels.

(2) Transport Logistics: Improve your logistics network to ensure efficient transport of raw materials (palm fruits and kernels) and the final product.

Palm kernels

Palm kernels

Step4. Equipment Upgrades

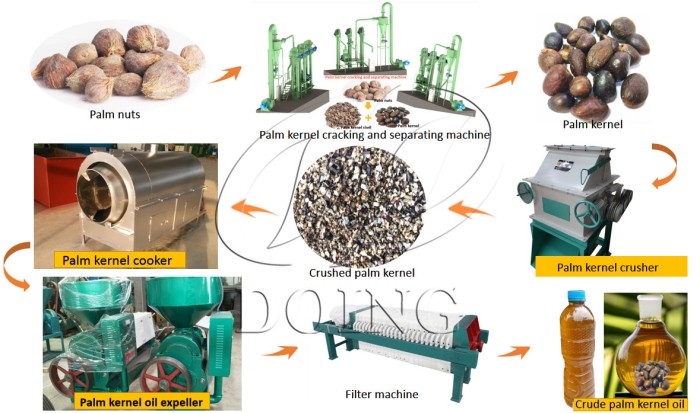

(1) Palm Kernel Pre-treatment Equipment: Invest in equipment for palm kernel cleaning, cracking and separating, crushing and cooking. This is essential to ensure high-quality palm kernel oil.

Palm kernel oil processing line

Palm kernel oil processing line

(2) Palm Kernel Oil Extraction Equipment: Install or upgrade to a mechanical press equipment or solvent extraction systems, depending on your palm kernel oil processing process choice.

(3) Palm Kernel Oil Refining Equipment: To meet food-grade quality or industrial specifications, add palm kernel oil refining units (degumming, deacidification, decolorization, deodorization, etc.) to ensure purity.

Palm kernel oil refining equipment

Palm kernel oil refining equipment

Step5. Staff Training and Hiring

(1) Skilled Labor: Hire or train additional operators, engineers and supervisors skilled in palm kernel oil processing process.

(2) Maintenance Teams: Ensure your maintenance teams are trained on the new palm kernel oil processing equipment to prevent downtime.

Step6. Quality Control and Certifications

(1) Quality Assurance: Implement stringent quality control procedures to ensure your palm kernel oil meets industry standards.

(2) Certifications: Obtain certifications (such as ISO 22000, GMP, or Kosher) for both the palm oil and palm kernel oil products to improve credibility and expand your market reach.

Step7. Marketing and Sales Strategy

(1) Brand Positioning: Market your expanded palm kernel oil production capacity and product range to new and existing customers.

(2) Product Diversification: Highlight the use of palm kernel oil in various industries, such as food, cosmetics and industrial applications, to attract more customers.

Step8. Sustainability and Environmental Considerations

(1) Waste Management: Incorporate efficient waste management systems to handle by-products, such as palm kernel cake.

(2) Sustainable Practices: Adopt sustainable practices in sourcing palm kernels and processing the palm kernel oil to align with global environmental standards.

Step9. Turnkey Solutions

(1) Project Management: Consider working with a turnkey solution provider that specializes in palm oil and palm kernel oil processing. These companies can offer end-to-end services, from design and procurement to installation and commissioning. For example, Henan Glory Company, a manufacturer specializing in the production of palm oil and palm kernel oil processing equipment, can not only provide a variety of equipment, but also have experienced technicians to be responsible for the installation and commissioning of the equipment, and can also provide personnel training services. You can rest assured to cooperate with it.

Palm kernel oil processing equipment

Palm kernel oil processing equipment

(2) Customization: Ensure that the turnkey provider offers customization options to suit your plant’s specific needs and future scalability.

In short, by following these steps, you can efficiently expand your palm oil processing plant into palm kernel oil production and meet growing market demand while improving profitability. If you need a customized solution, please contact Henan Glory Company!

PREV:Introduction of Henan Glory's different palm fruit sterilization equipment

PREV:Introduction of Henan Glory's different palm fruit sterilization equipment

NEXT:Maximize palm byproduct value: 5-step guide to add palm kernel oil production

NEXT:Maximize palm byproduct value: 5-step guide to add palm kernel oil production

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines