Palm oil refinery and fractionation plant

Small scale palm oil refinery plant

Small scale palm oil refinery plant

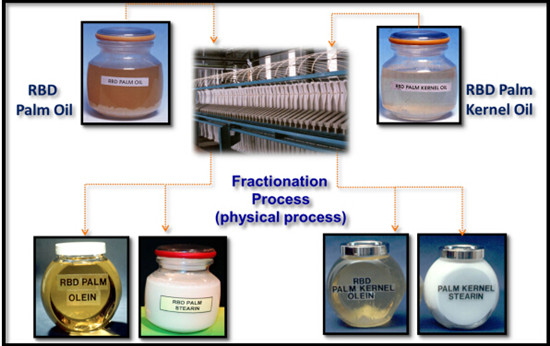

Palm oil refinery plant and palm oil fractionation plant all is the main equipment of further processing of palm oil. Palm oil refinery plant can get rid of harmful impyrities and needless substances in the crude palm oil and improve the color and flavor of palm oil. Palm oil fractionation plant can greatly maximize the value of products. After palm oil fractionation process, we can get palm olein and palm stearin.

[Recommend reading: small scale palm oil refining machine ]

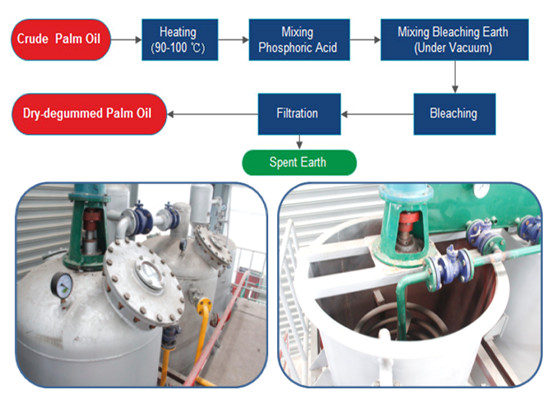

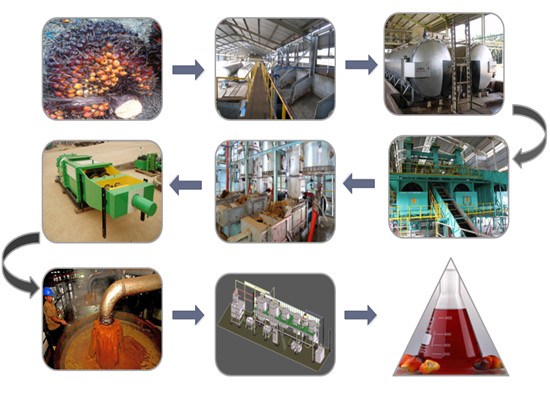

Work flow of palm oil refinery process:

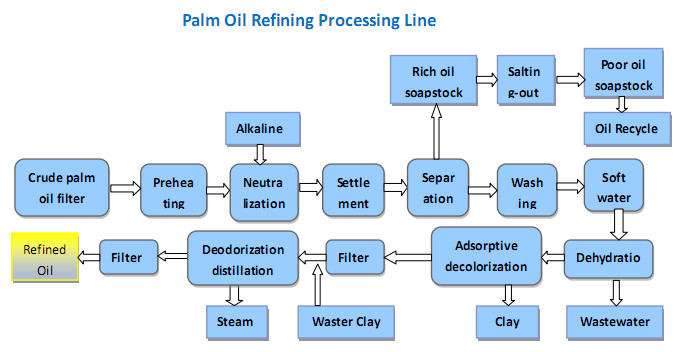

Palm oil refinery process flow diagram

Palm oil refinery process flow diagram

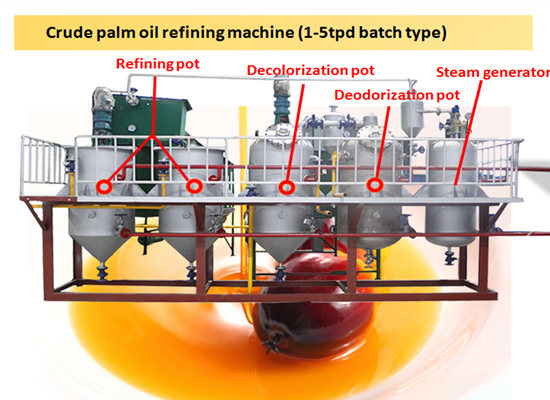

Palm oil refinery process description:

1. Degumming: pumping crude oil into oil refining tank, stirring quickly, and simultaneously heating by steam or heat-transfer oil(in plate pipes). Then the hot water is added for hydration and degumming.

2. Deacidification:alkali is added in the palm oil refining tank to remove the FFA. NaOH, not only used to neutralize free fatty acid, but also can act with other materials in oil , like, protein, mucilage, phospholipid, pigment, etc. All in all, alkali refining has the synthetic action of de-acid, degum, de-impurity,

3. Decolorization: inhaling the definite quantity white clay into the oil by vacuum, then they are continue stirred and heated for 25mins. Then pumping the oil and clay mixture into vibrating filter to remove the waste clay, the decolorization is finished.

4. Deodorization: Pumping the decolorized palm oil to the deodorization pot or the deodorization tower, it’s begin to heat. Then the direct steam is added to take the odors away.

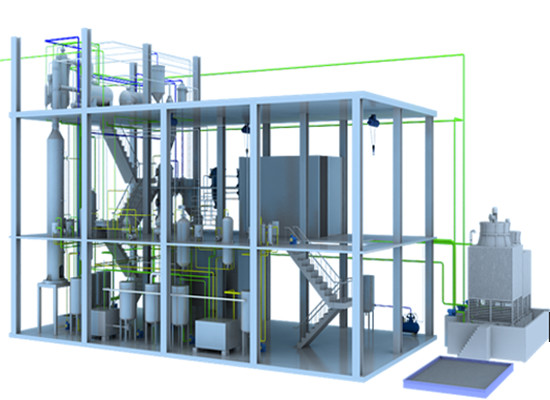

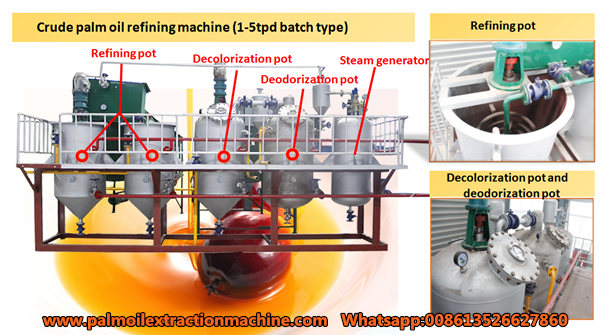

Photos of palm oil refinery plant:

Small scale palm oil refinery plant

Small scale palm oil refinery plant

After palm oil refinery process, we can get refined palm oil, till this step , most palm oil processing process is over, but if you have other uses and want to get other palm oil products, such as palm olein and palm stearin, palm oil fractionation plant is necessary.

Henan Doing Company palm oil fractionation plant adopts advanced crystallization and filtration technology to get different melting-point palm oil, including 14℃, 18℃, 24℃, 32℃ etc.

[Recommend reading: Palm oil fractionation plant ]

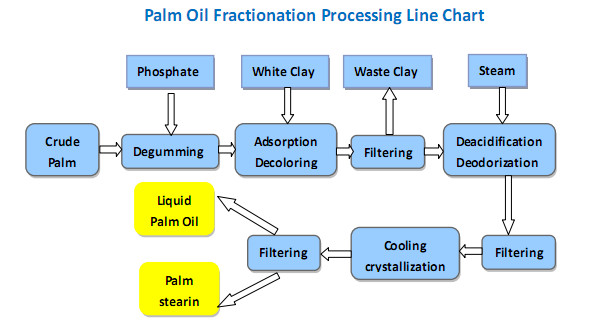

Work flow of Palm oil fractionation process:

Palm oil fractionation process flow diagram

Palm oil fractionation process flow diagram

Palm oil fractionation process description:

1.Pre-processing: oil is to be stored in a storage tank with constant stirring so as to avoid solid fat sedimentation and to ensure even crude oil to be sent to the palm oil fractionation plant.

2.Crystallization: crystallizer is a cylinder container with big cooling area and special stirrer which ensure the maximum evenness and the high efficiency of heat exchanger in crystallization process.

3.Filtering: crystallized RBD palm oil is conveyed to diaphragm filter though a filter pump. Finally unloading the palm stearin from the plates.

Palm oil fractionation plant

Palm oil fractionation plant

Photos of palm oil fractionation plant:

Small scale palm oil fractionation plant

Small scale palm oil fractionation plant

According to customers' requirements, our professional engineers would help customer design and install the whole crude palm oil refinery plant and palm oil fractionation plant with turnkey service and 1 year warranty.

PREV:Crude palm oil refining machine

PREV:Crude palm oil refining machine

NEXT:Nothing

NEXT:Nothing

Leave A Message

If you want to know more information about Palm oil refinery and fractionation plant . pls kindly leave your phone number, We will back to you ASAP once we got your message.

-

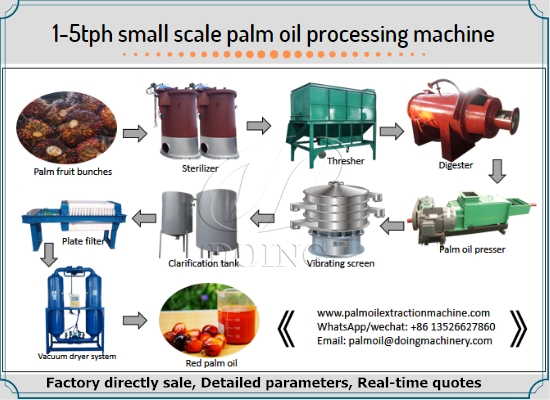

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines

-

What Are the Benefits of Using a Professional Vegetable Oil Refining Machine

What Are the Benefits of Using a Professional Vegetable Oil Refining Machine

-

Henan Glory 1T/H Plug-and-Play Palm Oil Press Unit

Henan Glory 1T/H Plug-and-Play Palm Oil Press Unit

-

Step-by-Step Process: How a Palm Kernel Oil Refining Machine Works

Step-by-Step Process: How a Palm Kernel Oil Refining Machine Works