Palm kernel & nut separation station

Factory direct sale contact number

Fiber polishing machine |

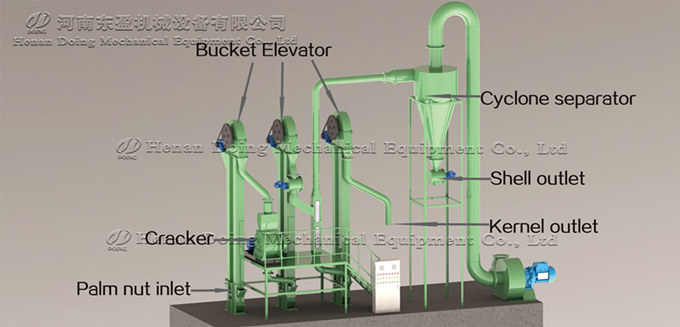

Palm kernel cracker machine |

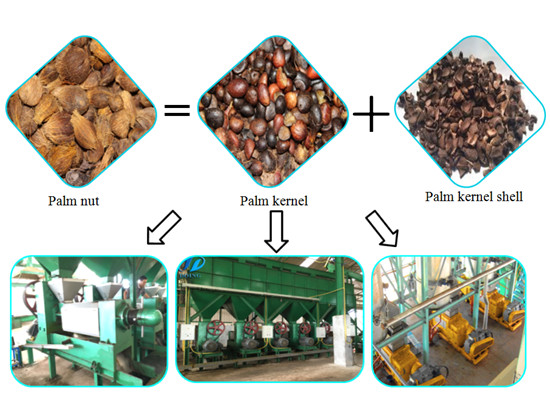

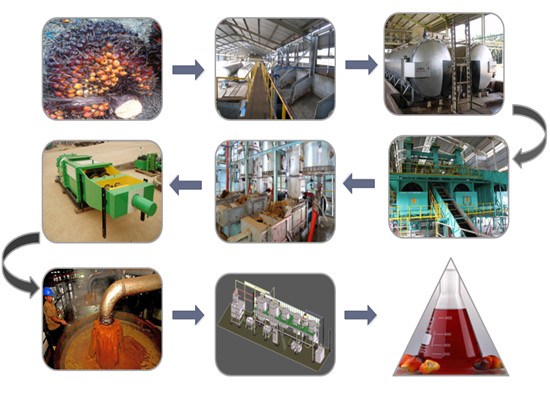

Palm kernel&nut separation station is the beginning of palm kernel oil processing machine.Palm kernel&nut separation station mainly used to process palm nut and get palm kernel. Firstly,The nut, little fiber and big impurity will be further separated by the polishing drum, palm shell and kernel will be separated by palm kernel cracking and separating system.

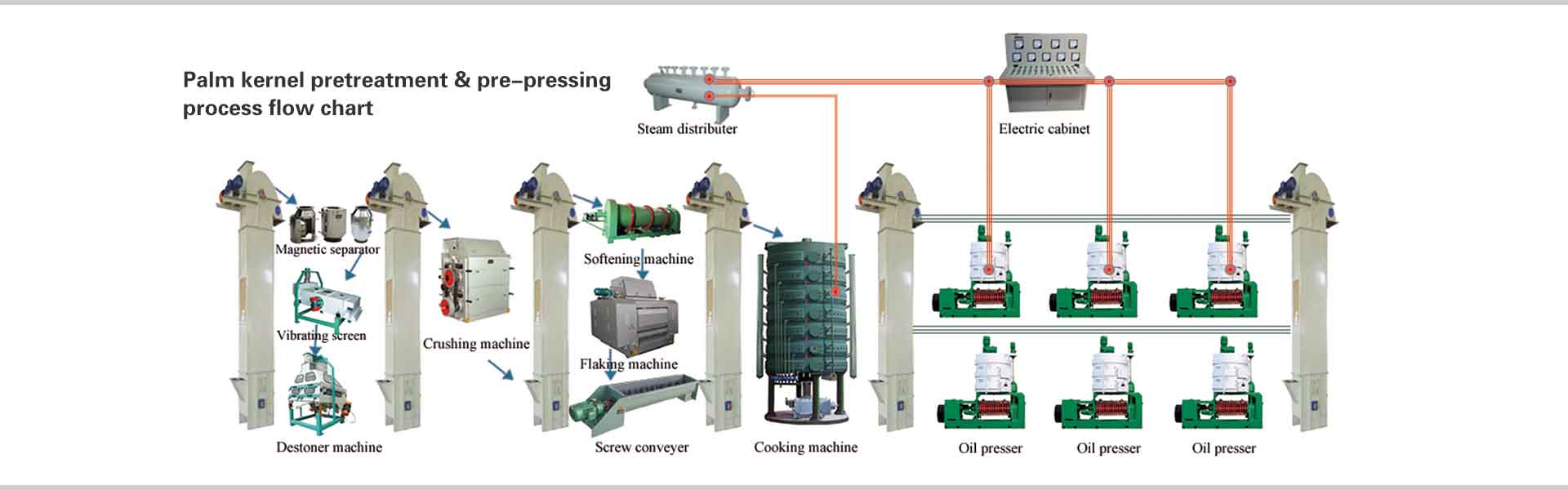

Firstly, the wet fiber and wet palm nut enter the cake breaker conveyor to be cracked, and mostly of the fiber should be separated by pneumatic fiber depericarper system. The nut, little fiber and big impurity will be further separated by the polishing drum(polishing drum also called fiber polishing machine). The separated nut should be sent to nut hopper through the pneumatic nut transport system, and then adopt the ripple mill to crack the nut, after palm kernel cracking machine, most of the shell and kernel will be separated by cracked mixture separating system, and the rest of mixture of palm kernel & shell enter to the special clay bath separating system to separate them, after palm kernel cracking and separating process , we could get pure kernel(The shell content in kernel <6%),which should be conveyed to the kernel silo to dry. After dried moisture as 7%, the kernel will be conveyed to kernel storage bin for storage; Usually the dry kernel’s capacity ratio is 4% . So it should be collected until enough quantity, and then be sent to the palm kernel oil mill; For the separated shell, it should be conveyed to shell temporary bin as the spare boiler fuel.

Firstly, the wet fiber and wet palm nut enter the cake breaker conveyor to be cracked, and mostly of the fiber should be separated by pneumatic fiber depericarper system. The nut, little fiber and big impurity will be further separated by the polishing drum(polishing drum also called fiber polishing machine). The separated nut should be sent to nut hopper through the pneumatic nut transport system, and then adopt the ripple mill to crack the nut, after palm kernel cracking machine, most of the shell and kernel will be separated by cracked mixture separating system, and the rest of mixture of palm kernel & shell enter to the special clay bath separating system to separate them, after palm kernel cracking and separating process , we could get pure kernel(The shell content in kernel <6%),which should be conveyed to the kernel silo to dry. After dried moisture as 7%, the kernel will be conveyed to kernel storage bin for storage; Usually the dry kernel’s capacity ratio is 4% . So it should be collected until enough quantity, and then be sent to the palm kernel oil mill; For the separated shell, it should be conveyed to shell temporary bin as the spare boiler fuel.

Palm kernel cracaking and separating machine (detail information you can watch : Palm kernel cracker and separator machine running video)

More information about palm kernel&nut separation station ,please browse palm kernel cracaking and separating machine.

Leave A Message

If you want to know more information about Palm kernel & nut separation station . pls kindly leave your phone number, We will back to you ASAP once we got your message.

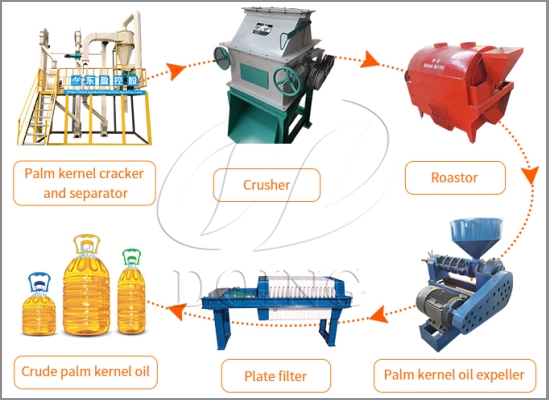

Palm kernel oil expeller

Products

palm oil mill plant projects

Palm Oil Extraction FAQ

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines

recommend products