What should be avoided during palm kernel oil production?

Palm kernel oil production is a complex process that demands attention to detail and strict adherence to best practices. By avoiding certain common mistakes, producers can ensure a high-quality product and optimize profitability. Henan Glory, a manufacturer of palm kernel oil production machine, will give some suggestions based on the experience of palm kernel oil production projects. Below are some points that should be avoided during palm kernel oil production.

1. Using Low-Quality Raw Materials

The quality of palm kernels directly impacts the oil’s purity and yield. It is vital to source fresh, mature kernels from reliable suppliers. Avoid using moldy or contaminated kernels, as they can lead to poor-quality oil and affect the palm kernel oil production process.

2. Inadequate Machinery Maintenance

Properly maintained machinery ensures smooth production and prevents costly breakdowns. Skipping regular inspections or neglecting routine maintenance can lead to inefficiencies and reduced palm kernel oil production output. Invest in high-quality equipment and follow a strict maintenance schedule to avoid these issues.

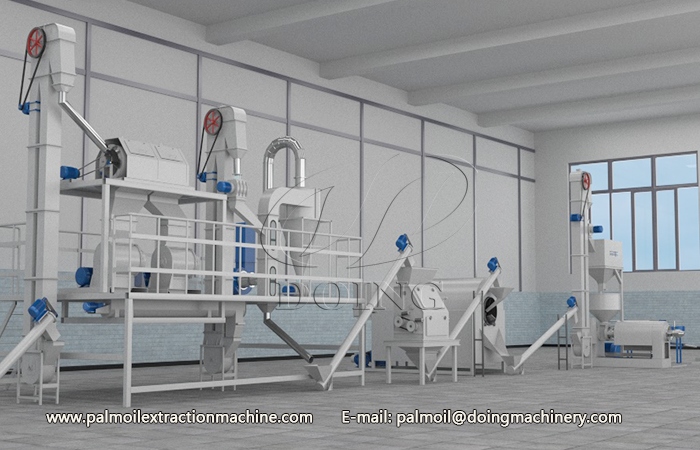

3D animation of small scale palm kernel oil press production line

3D animation of small scale palm kernel oil press production line

3. Poor Storage Practices

Storage plays a critical role in maintaining oil quality. Avoid storing palm kernels or oil in areas exposed to moisture, heat, or contaminants. Use airtight, temperature-controlled storage units to preserve the oil's freshness and extend its shelf life.

4. Ignoring Safety Protocols

Palm kernel oil production involves high temperatures and heavy machinery. Ensure all workers follow safety protocols and wear appropriate protective gear. Ignoring safety measures can lead to accidents and production delays.

5. Environmental Neglect

Sustainable practices are essential in today’s market. Avoid improper waste disposal and implement eco-friendly methods to minimize environmental impact. Adhering to sustainability standards can boost your brand's reputation and attract eco-conscious consumers.

Palm kernel oil mill palnt

Palm kernel oil mill palnt

By avoiding these points during palm kernel oil production, palm kernel oil producers can enhance product quality, improve efficiency, and achieve long-term success. Focus on best practices and continuous improvement to stay competitive in this thriving industry! Henan Glory has been manufacturing palm oil and palm kernel oil production machines for more than 10 years, and has also done palm oil and palm kernel oil production projects in Nigeria, Congo, Indonesia and other countries, proposing suitable production plans for customers, and equipped with palm oil and palm kernel oil production machines. Henan Glory is also looking forward to cooperating with more customers.

PREV:1TPH Palm Oil Frame All-in-One Machine: Revolutionizing Palm Oil Production

PREV:1TPH Palm Oil Frame All-in-One Machine: Revolutionizing Palm Oil Production

NEXT:What are the differences between the skid-mounted and the ordinary palm oil processing line?

NEXT:What are the differences between the skid-mounted and the ordinary palm oil processing line?

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines