What is palm oil refining process?

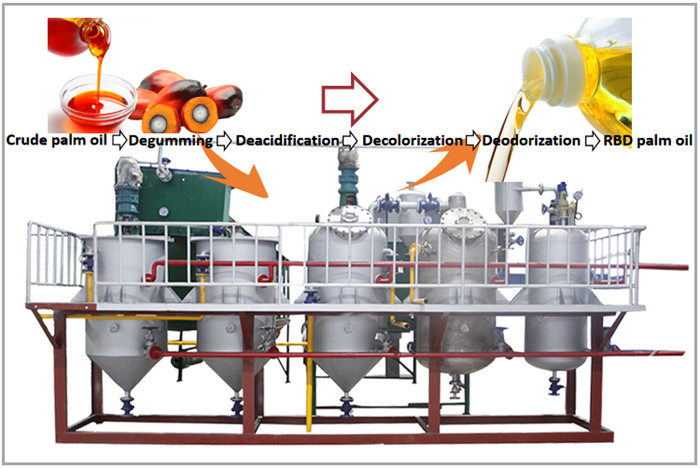

After palm oil is extracted, crude palm oil generally cannot meet the edible standard. So crude palm oil is sent to a palm oil refinery for refining in order to further improve the oil quality. Palm oil refining process include degumming, deacidification, decolorization and deodorization. Refined palm oil can be gotten after that. In addition, according to the needs of different customers, palm oil can be further extracted into palm olein and stearin.

There are two options for refining process including physical refining process and chemical refining process. Chemical refining process is suitable for most oil seeds and can be used in large or small quantities and physical refining process is more practical for cooking oil with low gum content and high acid value,such as palm oil, palm kernel oil, and coconut oil, etc. Therefore, generally speaking, physical refining is more suitable for palm oil especially in large quantity. This article focuses on the physical palm oil refining process.

The following is a brief introduction to the palm oil refining process.

Palm oil refining process

Palm oil refining process

1. Degumming section:

Heating the crude palm oil is up to 30-50℃, add 85% or 75% food-grade phosphoric acid, and adding 0.05%-0.2% of the phosphoric acid to account for the weight of the oil. The purpose is to convert non-hydrated phospholipids into hydrated phospholipids, and aggregate into clusters to discharge impurities .

2. Deacidification section:

Unrefined crude oil contains free fatty acids, which will make the oil easily rancid, so it needs to be deacidified to remove free fatty acids. Deacidification is carried out in a deacidification tank by distillation, or in a deodorization tower together to relieve free fatty acids and other odorous substances. Afterwards, free fatty acids can also be collected by condensation for other purposes.

3. Decolorization section:

In the process of negative pressure decolorization, due to the low operating pressure and weak thermal oxidation side reactions, negative pressure decolorization is generally used, and the vacuum degree is 0.096mPa. In a vacuum state, it is usually carried out in a decolorizing tower, adding 1-3% decolorizing agent accounting for the weight of the oil for physical adsorption and usually using clay. The gums and pigments are removed together by the adsorption of the clay. In addition, through the filtration process of the leaf filter, the waste white clay will be discharged.

4. Deodorization section:

Deodorization is to deodorize the oil by introducing a certain amount of superheated steam to strip the oil under the high temperature of 220-260 °C, using the principle of different volatilization points of oil and malodorous molecular substances. There is an another option. Deacidification and deodorization are carried out together by distillation in a deodorization tower. The main body of the deodorization section of the palm oil refinery is the combined packing deodorization tower, which is divided into two parts. The slender part above is the deacidification part, and the thick part below is the deodorizing part. High-temperature steam is input to achieve the purpose of deodorization, removing free fatty acids and odor components from the oil.

5. Fractionation section:

Fractionation oil consists of triacylglycerol with different melting points, under certain temperature, separating the olein and stearin according to their different melting points and melting percentage. Palm oil fractionation equipment is divided into three parts, preheating, cooling and crystallization and filtering. After going through a palm oil fractionation plant, palm oil is separated into several fractions with different melting points, which can be used for different industrial purposes.

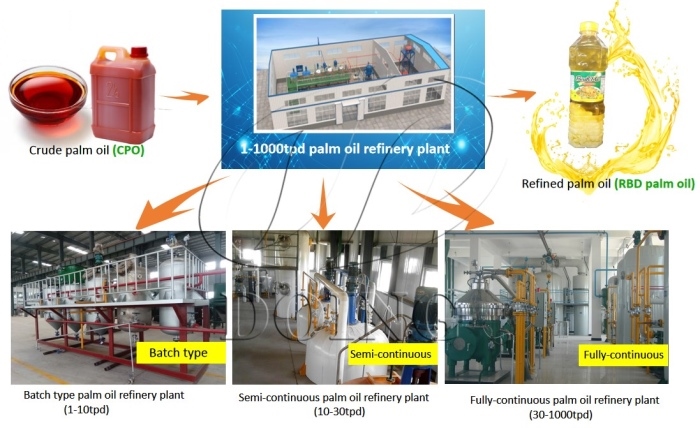

Due to the difference in crude oil quality and parameters, the palm oil refining process is different. Henan Glory Company's engineers can design the production line according to the actual situation of crude oil. In addition, according to the degree of automation and processing capacity of the refining production line, Henan Glory Company can provide the following palm oil refinery type to choose.

Palm oil refinery type:

Palm oil refinery type

Palm oil refinery type

1-20tpd small Palm Oil Refinery

20-50tpd medium-sized palm oil refinery

50-600tpd fully automatic large palm oil refinery

1-600tpd palm oil separator

The Glory Company has been focusing on palm oil processing machine for decades. If you are interested in setting up a palm oil refining process, our professional engineers can help you design and install it according to your capacity and requirements. If you have any ideas on palm oil processing , please feel free to contact us.

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines