How to save palm oil processing costs?

The palm oil processing costs contain many points, such as raw materials costs, the palm oil processing plant construction cost, the palm oil processing production line production cost, etc. If you want to save palm oil processing costs, you can consider that from these three points.

1. Reduce raw materials costs

Generally speaking, who starting palm oil processing business has his own palm tree plantation, which can not only reduce raw materials costs, but make sure the stability of the raw materials. Besides, the palm oil processing plant often are built next to the palm tree plantation, which can not only reduce the transportation cost, but ensure the fresh of the palm fruit bunches.

Raw material palm fruit bunches transportation picture

Raw material palm fruit bunches transportation picture

2. Reduce palm oil processing plant construction cost

The palm oil processing plant construction cost contains the workshop construction cost and the palm oil processing production line cost. If you have already had your own workshop, you will save a lot of money. If you don't have it, you had better find local construction team to build the palm oil processing workshop, which will be cheaper than turn-key project service.

Modern palm oil processing plant

Modern palm oil processing plant

Next is the palm oil processing production line cost. The cost of a full set large scale palm oil processing production line is very high, and the production cost is closely related to the mechanization degree of the palm oil processing production line. If the local labor cost is not very high, you can also choose simple palm oil processing machine which is not full-automatic to save the purchase cost of palm oil processing machine.

Under the premise of ensuring the quality of palm oil, Henan Glory Company designed different mechanization degree of palm oil processing production line. You can choose them according to your needs. Of course, the higher mechanization degree, the cost will be higher, too.

1) Simple type palm oil processing production line

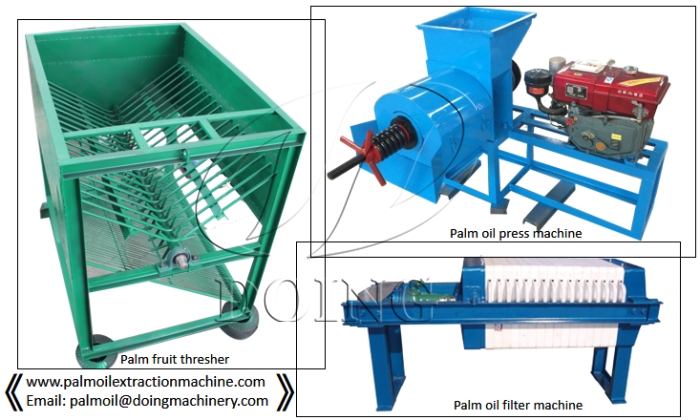

The simple type palm oil processing production line includes three machines: palm fruit threshing machine, palm oil press machine and plate filter.

Simple type palm oil processing production line

Simple type palm oil processing production line

The 1-2tph simple fruit thresher can separate the palm fruit from the palm fruit bunch, which is low in cost and high in efficiency. For the palm oil press machine, we have two different specifications of machines: 500kg/h single screw palm oil press is used to extract oil from palm fruit, with low residual oil rate. And this oil press also has two power systems, diesel and motor, which can be well adapted to the different power conditions of customers. The 1-2tph double screw oil press is more efficient, has a low residual oil rate, and is equipped with a hydraulic pump station, which can be well adapted to the palm oil processing production line. Finally, it is a 500-1000kg/h plate filter to remove impurities in the crude oil, so as to obtain clean crude palm oil, which has a wider range of uses and a good filtering effect. While minimizing the cost of mechanized processing, you can also get good quality palm oil.

2) Installation-free palm oil processing production line

Installation-free palm oil processing production line is 1-2t/h processing capacities, which contains sterilization machine, threshing machine, two palm oil press machine, oil clarification machine, filter machine and vacuum drying machine. As all the machine is welded to the frame, when they arrived in customers' factory, it only need to connect different frames and then the palm oil processing production line can run.

1-2tph installation-free palm oil processing production line

1-2tph installation-free palm oil processing production line

In this set of palm oil processing production line, the palm fruit sterilization machine is heated by steam from hot water. So it doesn't have steam boiler, which can save the costs. Besides, there is no digesting machine, which is instead by a set of palm oil press, which also can save costs.

3) Complete small and large scale full-automatic palm oil processing production line

We have 1-2t/h and 5t/h complete small scale full-automatic palm oil processing production line and the complete large scale full-automatic palm oil processing production line is above 10t/h.

Palm oil processing production lines with different processing capacity

Palm oil processing production lines with different processing capacity

The costs of complete full-automatic palm oil processing production line will be higher, but the production cost will be cheaper because it will need little labor.

3. Reduce the palm oi processing production cost

To reduce the palm oi processing production cost, you can improve the automation degree or maximize resource utilization. For example, the empty palm fruit bunches can be burned in the steam boiler to save fuel and wood.

The above is our solution for saving palm oil processing costs, and I hope it will be helpful to you. In addition to the complete processing production line, Henan Glory also produces single machines for other conventional oil press processing and palm kernel oil processing machines. If you have any needs, please feel free to consult us.

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines