Is there a equipment that turns red palm oil into vegetable oil?

To turn red palm oil into vegetable oil, we need red palm oil refinery equipment. Using red palm oil refinery equipment, we not only can make the color of red palm oil lighter, but remove harmful impurities and useless substances in red palm oil, so as to improve the storage stability and smell. According to processing capacity and budget, Henan Glory Oils company can provide 3 types of red palm oil refinery equipment.

Refining Equipment Model

Refining Equipment Model

▲The first type: Batch red palm oil refinery equipment

Batch red palm oil refinery equipment is suitable for the processing capacity of less than 20TPD red palm oil. Its advantage is that the operation of the equipment is simple and flexible, the investment is small, and it is suitable for frequent replacement of various vegetable oils. Operated by electric heating and thermal oil heating.

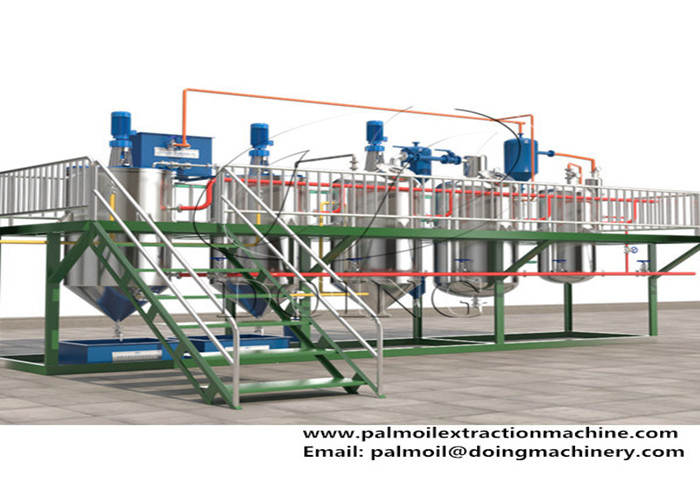

▲The second type: Semi-continuous red palm oil refinery equipment

Semi-continuous red palm oil refinery equipment is suitable for the processing capacity of 5-30TPD red palm oil. Its advantages are high efficiency, energy saving and environmental protection, high additional output value and relatively low cost.

▲The third type: Full continuous red palm oil refinery equipment

Full continuous red palm oil refinery equipment is suitable for the processing capacity of more than 30TPD red palm oil. All units of continuous refinery equipment are continuous production. This refinery process has advantage of: less consumption, less oil lost and more steady quality of refinery red palm oil.

Red palm oil refiner equipment

Red palm oil refiner equipment

The above three kinds of red palm oil refinery equipment has different processing capacities and cost, but they has same palm oil refining process, including degumming, deacidification, decolorization and deodorization. Let's take a small batch red palm oil refinery equipment chemical process as an example to describe the process of red palm oil refinery.

◆Process one: Degumming

Add food-grade phosphoric acid with a concentration of 85% or 75% into red palm oil, and the amount of phosphoric acid added is 0.05%-0.2% of the oil weight.

◆Process two: Deacidification

Add a certain concentration and a certain amount of NaOH into red palm oil to carry out acid-base neutralization reaction, so as to achieve the purpose of removing free fatty acids in oil.

◆Process three: Decolorization

Add 1-3% of decolorizing agent into red palm oil which accounts for the weight of the oil, carry out physical adsorption, and then use filtering equipment to separate the red palm oil from the decolorizing agent, so as to achieve the purpose of decolorizing.

◆Process four: Deodorization

Under a high temperature of 220-260°C and a certain vacuum condition, a certain amount of superheated steam is introduced to strip the red palm oil, and the purpose of deodorization is achieved according to the difference in the volatilization point of the oil and volatile small molecular substances.

Continuous Refining Plant

Continuous Refining Plant

If the processing capacity of red palm oil is large, semi-continuous red palm oil refinery equipment and full continuous red palm oil refinery equipment are recommended for physical refining. These two types of red palm oil refinery equipment have low oil loss and low production consumption. Henan Glory Oils company that has been in the industry for more than 10 years, we have lots of experience. If you want to know more details about vegetable oil refinery, please feel free to contact us.

PREV:How to build a palm oil production line with low budget?

PREV:How to build a palm oil production line with low budget?

NEXT:How do I get palm kernel oil with palm kernel oil processing equipment ?

NEXT:How do I get palm kernel oil with palm kernel oil processing equipment ?

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines