What Types of Machinery are Used in Crude Palm Oil Refining?

If you’re exploring palm oil refining solutions, you’re likely seeking efficient, cost-effective methods for producing high-quality RBD (Refined, Bleached, and Deodorized) palm oil. Understanding the machinery used in crude palm oil refining is crucial—whether you’re planning a new facility, upgrading existing palm oil refining machinery, or optimizing production.

The palm oil refining process typically includes degumming, deacidification, bleaching, and deodorization. Depending on your production goals, you can choose from batch-type, semi-continuous, or fully continuous refining types. Each refining type uses specific machinery tailored to different capacities and quality requirements.

1. Batch-Type Refining Machinery

Batch refining is a semi-automated type in which each stage—degumming, deacidification, bleaching, and deodorization—is performed sequentially in separate vessels. This batch type of crude palm oil refining is specifically designed for small-scale operations (1–20 tons/day), as it offers excellent flexibility and a cost-efficient initial investment.

Batch-type palm oil refining machinery

Batch-type palm oil refining machinery

Key Palm Oil Refining Machinery:

Degumming Tank: It is used to remove phospholipids (gums) by adding water or acid (e.g., phosphoric acid) under heated conditions.

Neutralization Tank: An alkali (e.g., NaOH) is added to the tank to neutralize free fatty acids (FFA), forming soapstock.

Bleaching Tank: It is filled with an activated clay to adsorb pigments and impurities.

Plate Filter: It removes spent bleaching earth from the oil and requires manual operation to discharge the filter cake.

Deodorization Tank: It uses high-vacuum steam stripping to remove volatile odors at temperatures of 240–260°C.

This configuration is ideally suited for small-scale palm oil refining mills, startups, and those who require flexibility to process different oil seeds, as well as for those seeking a lower initial investment.

2. Semi-Continuous Refining Machinery

Semi-continuous refining combines batch and continuous types, in which some stages (e.g., degumming, deacidification) are batch-operated, while others (e.g., bleaching, deodorization) are continuously operated. It is suitable for medium-scale refineries with a production capacity of 20–50 tons/day.

Semi-continuous palm oil refining machinery

Semi-continuous palm oil refining machinery

Key Palm Oil Refining Machinery:

Degumming & Neutralization Tank: It is a combined vessel designed for adding acid or water and conducting alkali neutralization.

Centrifuge: It separates soapstock from neutralized oil highly efficiently.

Leaf Filter: It is an automated filtration device that uses filter leaves for efficient clay removal.

Deodorization Tower: It enables continuous steam stripping with internal automated packing.

This type is ideal for medium-scale palm oil refining mills seeking to increase production capacity and mills that are aiming to reduce labor costs through partial automation.

3. Fully Continuous Refining Machinery

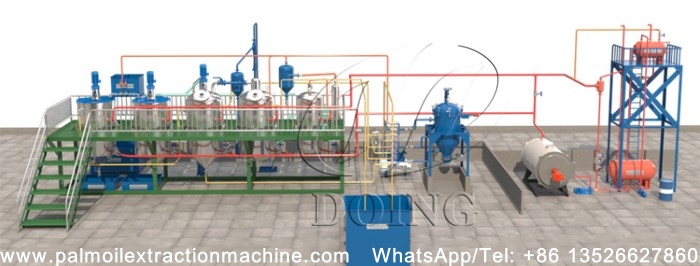

Fully continuous refining is a fully automated, high-capacity type (50+ tons/day) in which all stages operate simultaneously without interruption. It is ideal for large-scale industrial production with strict quality control.

Fully continuous palm oil refining machinery

Fully continuous palm oil refining machinery

Key Palm Oil Refining Machinery:

Pre-Heater & Heat Exchanger: They recover heat from the deodorized oil to preheat the incoming crude oil, significantly improving energy efficiency.

Degumming & Neutralization Section:

Pre-Mixer: Combines oil with acid/water or alkali for rapid reaction.

Centrifugal Separator: It continuously removes gums and soapstock from the palm oil.

Bleaching Section:

Pre-Mixer: It blends oil with bleaching earth before the oil enters the bleaching tower.

Bleaching Tower: It is a tower where oil flows through with heating coils under vacuum conditions.

Polishing Filter: It removes fine particles from the palm oil after bleaching.

Deodorization Section:

High-Pressure Steam Injector: It introduces steam for stripping volatile compounds.

Deodorization Tower: It effectively maximizes the contact area between oil and steam.

This advanced configuration is specifically tailored for large-scale palm oil refining mills, factories pursuing production efficiency and stable quality, as well as palm oil producers seeking to reduce operating costs through full automation and energy recovery.

At Henan Glory Company, we help you select, install, and maintain crude palm oil refining machinery that aligns with your requirements and growth goals. Contact us for a free consultation or a customized solution proposal tailored to your needs.

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines