How to set up a small scale palm kernel oil mill plant in Nigeria?

If you are plan to look for a profitable business opportunity in Nigeria, set up a small scale palm kernel oil mill plant in Nigeria is a good choice. In this article, we will introduce you to the detailed process of setting up a small scale palm kernel oil mill plant in Nigeria.

Small scale palm kernel oil production equipment

Small scale palm kernel oil production equipment

Process 1: Make a business plan

A business plan is the first step towards starting any business. It helps determine the amount of capital required and how it should be used. In a way, it acts as a road-map for the business operations. It is also a key document in helping secure additional capital, whether through strategic partnership or lending, if required.

Process 2: Prepare start-up capital

This is the initial investment required to set up a palm kernel oil mill plant in Nigeria. This cost can vary depending on the location of land chosen, land-size and capacity of palm kernel production plant decided upon etc. If you don't have the necessary funds to start your business as the sole proprietor, then you can exercise options such as entering into a partnership or sourcing capital from the bank of industry or other lending institutions in Nigeria.

Process 3: Select the address for setting up the factory

Finding land is an important step. You will want to choose a location suited for production purposes yet not too isolated where distance becomes a hindrance for operation. Once the land has been bought, you need to set up the palm kernel oil mill plant, which will house your raw materials and your entire palm kernel oil production line.

Palm kernel oil production equipment

Palm kernel oil production equipment

Process 4: Order palm kernel oil production equipment

The following palm kernel oil production equipment is required to set up a small scale palm kernel oil mill plant: palm kernel cracking and separating equipment, crusher, cooker, palm kernel oil presser, plate filter. If you have higher quality requirements for palm kernel oil, you can also refine the processed crude oil later. The batch type refinery plant and semi-continuous refinery plant produced by our company have low cost and low losses, which is suitable for small scale palm kernel oil mill.

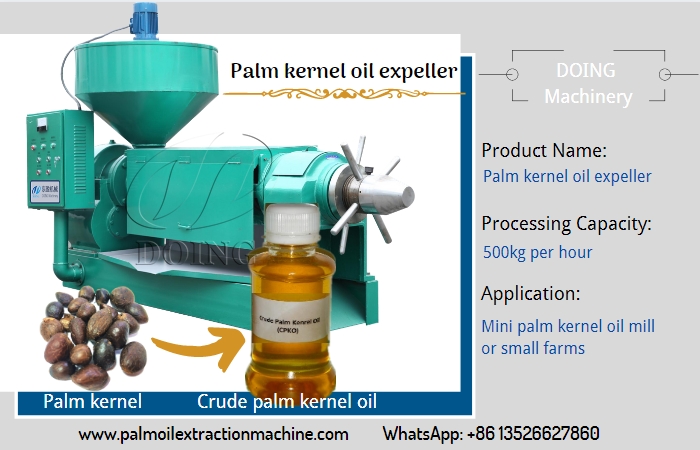

Palm kernel oil expeller

Palm kernel oil expeller

Our company can provide customized palm kernel oil production equipment solutions according to different situations and requirements of customers. Welcome to order equipment from our company.

Process 5: Begin production

With the palm kernel oil mill plant established, you can now start producing palm kernel oil. Palm kernel oil mill in Nigeria

Palm kernel oil mill in Nigeria

The above are the basic steps to set up a small scale palm kernel oil mill plant in Nigeria. And we are building our own cooking oil equipment processing factory in Nigeria. It will be more favorable to order palm kernel oil production equipment from our company. We also have many similar project cases in Nigeria. If you trust our company, we can help you plan factory construction and provide palm kernel oil production equipment. Looking forward to your news, my whats app: 86 13526627860.

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines