Introduction to palm oil processing and refining process

Introduction to palm oil processing process

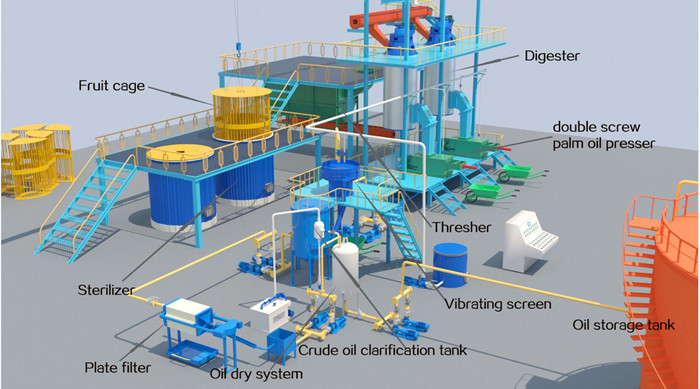

Palm oil processing process for production line

Palm oil processing process for production line

1. Sterilization Station

Putting the palm fruit bunches into the sterilization tank for cooking is the first step. It has two purposes: on the one hand, it increases the humidity of the fruit, which is beneficial to the separation of the fruit from the fruit bunches; On the other hand, it destroys the activity of the fat-decomposing enzyme and prevents the content of free fatty acids (FFA) from increasing, so as to slow down rancidity.

2. Threshing Station

Conveyor scrapers will transport the fruit bunches in the fruit cages to the thresher. The threshing station usually adopts a drum type threshing machine, which is generally 2.5 meters long, and the longer it is, the better the threshing effect can be guaranteed. In this way, palm fruit will be separated from the palm fruit bunches.

3. Digesting and Pressing Station

Conveying auger will transport these palm fruits to the palm fruit digester. The pulp is stirred and broken in the digester tank and becomes finely divided, which can improve the oil yield. In addition, a portion of the oil produced during the digesting process can be collected in the lower oil collection tank. The oil presser is generally placed under the digester to facilitate timely pressing. Henan Glory Company can provide different types of pressing machines which can be chosen according to processing capacity or your requirements.

4. Oil Clarification Station

For the filtration stage, a vibrating screen, an crude oil clarification tank and a plate filter are generally configured to filter different impurities in the crude oil and clean crude oil can be provided. Then use a vacuum drying system to evaporate excess water for easier storage. Finally, the clean crude oil is introduced into the crude oil tank for temporary storage. At this point, the palm oil processing process is completed.

Introduction to palm oil refining process

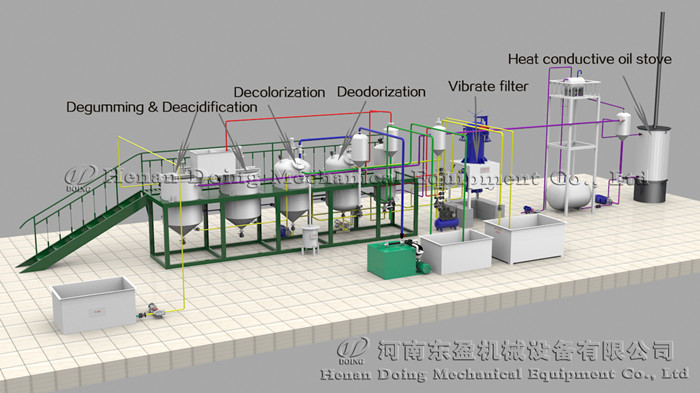

Specific process for refining production line

Specific process for refining production line

1. Degumming

Palm oil refining process includes degumming, deacidification, decolorization and deodorization. Degumming is the first step. Degumming is the removal of phospholipids and peptizing substances from crude oil. These impurities will not only damage the stability of oil storage, but also affect subsequent refining steps. Therefore, it is necessary to place degumming in the first step. It is commonly believed that 85% or 75% food grade phosphoric acid is added to the deacidification equipment, and the amount of phosphoric acid added is 0.05%-0.2%, accounting for the weight of the oil to deacidify.

2. Deacidification

Unrefined crude oil contains free fatty acids, which will make the oil easily rancid, so it needs to be deacidified to remove free fatty acids. There are two deacidification methods, namely alkali refining deacidification and distillation. Alkali refining and deacidification is by adding a certain concentration and a certain amount of NaOH to carry out acid-base neutralization reaction, so as to achieve the purpose of removing free fatty acids in oil. Distillation method, also known as physical refining method, uses high temperature steam to remove free fatty acids in oil, which is often used for refining oil seeds with high acid value and low gum.

3. Decolorization

Next step is decolorization. The principle of decolorization is to use adsorbents to absorb the pigments and other impurities in the hot oil, and then filter them together. In a vacuum state, it is usually carried out in a decolorizing tower, adding 1-3% decolorizing agent accounting for the weight of the oil for physical adsorption, and then using a filtration device to separate the oil from the decolorizing agent, so as to achieve the purpose of decolorization. Moreover, it is a necessity for better effect that this process requires high temperature, high vacuum and hot steam.

4. Deodorization

The final step is deodorization. Deodorization is to use the principle of different volatilization points of oil and odorous molecular substances to deodorize. Under the condition of high temperature of 220-260℃ and vacuum, a certain amount of superheated steam is introduced to strip the oil to achieve the purpose of deodorization. Due to the need for high temperature conditions, carbon steel will generate manganese under high temperature conditions, which is harmful to the human body. Therefore, the material of the deodorizing tower needs to be stainless steel.

The above is an introduction on complete process of palm oil processing and refining. Henan Glory Company has the ability to provide related crude palm oil production process. Besides, our professional engineers can design for your requirements, no matter what kind of pressing or refining production equipment you need, or even a complete palm processing line. If you intend to start a business related to palm oil, please feel free to contact us.

PREV:How is palm kernel oil produced?

PREV:How is palm kernel oil produced?

NEXT:Precautions for the use of palm kernel cracking and separating machine

NEXT:Precautions for the use of palm kernel cracking and separating machine

Leave A Message

If you want to know more information about Introduction to palm oil processing and refining process . pls kindly leave your phone number, We will back to you ASAP once we got your message.

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines