Physical refining for palm kernel oil

Factory direct sale contact number

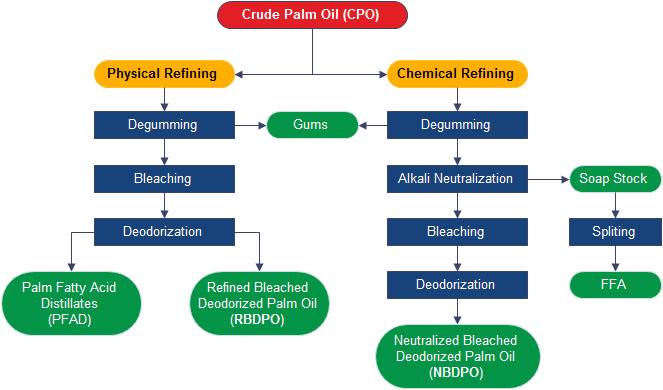

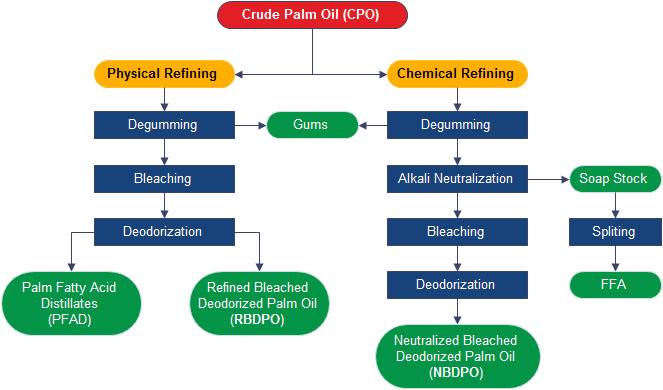

Two processes have been developed for the refining of edible oils and fats, i.e. physical and chemical refining; the decision which process to use depends on the types and qualities of the crude oil to be processed . The names physical and chemical refining come from the process technology used to remove the free fatty acids (FFA) that are responsible for the oil acidity. Physical refining for palm kernel oil is a process making use of the lower boiling point of the FFA compared to the boiling point of the triglyceride oil. In chemical or alkaline refining for palm kernel oil, an alkali is used to neutralise the FFA.

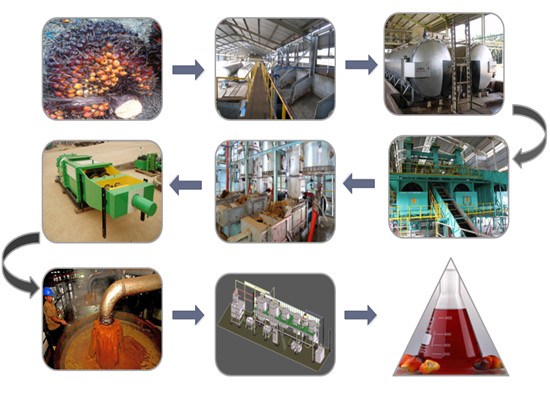

Palm kernel oil refining process is the same with palm oil refining process

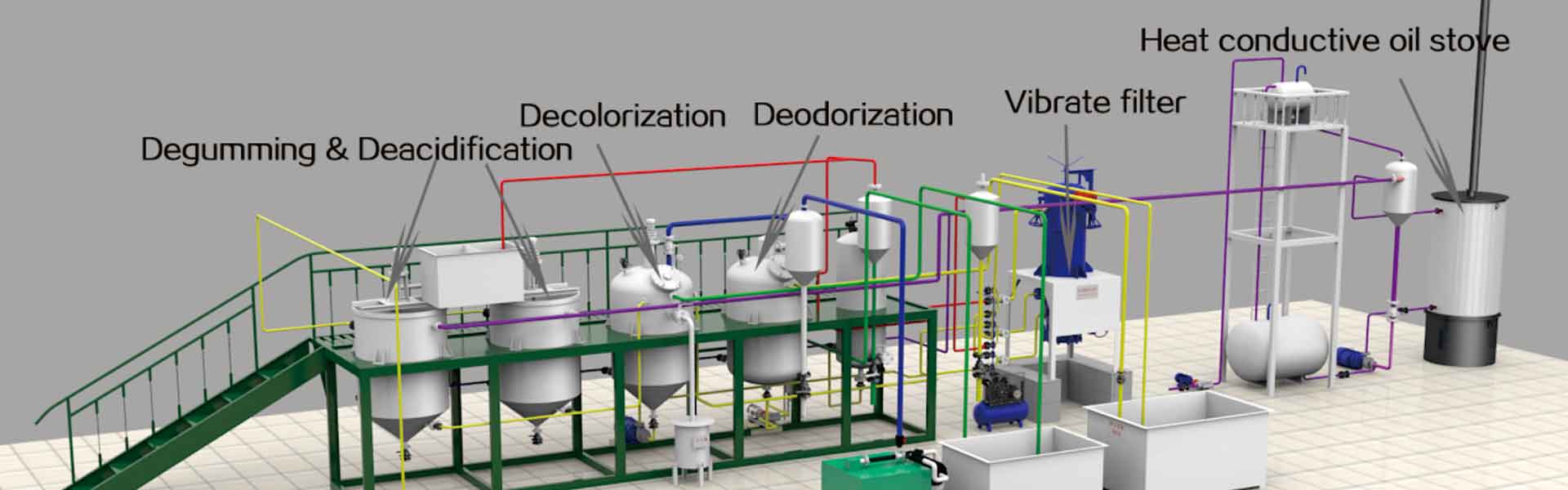

Palm kernel oil refining is a step by step process. Refining removes phospholipids, pigments, off-flavors, free fatty acids and other impurities in the crude oil. The entire palm kernel oil refining process comprises degumming/neutralization, bleaching, and deodorization.

Physical refining is method that used for palm kernel oil refining process. Through this method, the free fatty acids are removed during the process of distillation, which is one stage of deodorizing. The crude oil should be thoroughly degummed to come up with effective results.

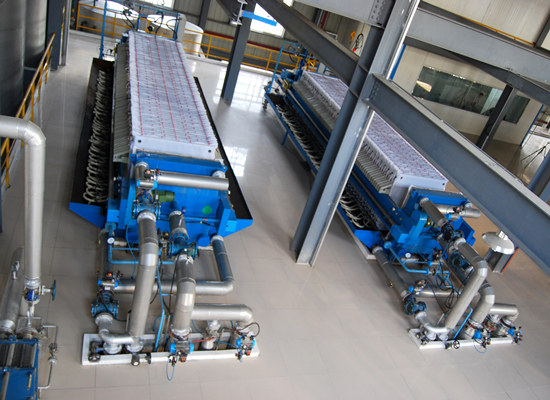

Palm kernel oil refining workshop

The physical refining process for palm kernel oil consists of three main parts:

1) Dry degumming:

In the dry degumming, the crude palm oil is mixed with food grade acid to remove the free fatty acids.

2) Bleaching:

degummed oil is mixed with the soil that is a vacuum level, where it is dried and de-aerated. The bleaching earth absorbs the main particles of color bodies as well as metal contamination and oxidizing materials in the oil.

3) Distillation / Deodorization:

The bleached oil is first de-aerated and heated where any remaining air and volatile materials are removed.

The oil then enters the deodorizer section in physical refining for palm kernel oil where the main body of free fatty acids and other volatile odor and taste substances are removed from the oil.

The oil leaving the deodorizer is cooled to storage temperature and then passed through one of two alternately working polishing filters.

The product obtained is refined bleached and deodorized oil (RBDO).

To a free flow fractionation process, the separation of the liquid phase from the solid phase is possible.

Related introduction of palm kernel oil refining process:

Palm kernel oil refining processing line adopts advanced and scientific physical refining and totally stainless steel tank refining. Palm kernel oil is non-drying oil with low gum content, which is suitable for physical refining. Fatty acid composes of 45%-51% lauric acid and 13%-25% cardamom acid. Palm kernel oil contains soap grade and food grade.The process of Palm kernel oil refinery is to refine the crude edible oil, to remove gossypol, protein, phospholipid, grume, moisture and other impurities, in order to reach the purchase of food and storage.The process of palm kernel oil refinery includes mechanical refinery method, chemical refinery method and physical refinery process refinery process.

Palm kernel oil refining process is the same with palm oil refining process

Palm kernel oil refining is a step by step process. Refining removes phospholipids, pigments, off-flavors, free fatty acids and other impurities in the crude oil. The entire palm kernel oil refining process comprises degumming/neutralization, bleaching, and deodorization.

Physical refining is method that used for palm kernel oil refining process. Through this method, the free fatty acids are removed during the process of distillation, which is one stage of deodorizing. The crude oil should be thoroughly degummed to come up with effective results.

Palm kernel oil refining workshop

The physical refining process for palm kernel oil consists of three main parts:

1) Dry degumming:

In the dry degumming, the crude palm oil is mixed with food grade acid to remove the free fatty acids.

2) Bleaching:

degummed oil is mixed with the soil that is a vacuum level, where it is dried and de-aerated. The bleaching earth absorbs the main particles of color bodies as well as metal contamination and oxidizing materials in the oil.

3) Distillation / Deodorization:

The bleached oil is first de-aerated and heated where any remaining air and volatile materials are removed.

The oil then enters the deodorizer section in physical refining for palm kernel oil where the main body of free fatty acids and other volatile odor and taste substances are removed from the oil.

The oil leaving the deodorizer is cooled to storage temperature and then passed through one of two alternately working polishing filters.

The product obtained is refined bleached and deodorized oil (RBDO).

To a free flow fractionation process, the separation of the liquid phase from the solid phase is possible.

Palm kernel oil refining processing line adopts advanced and scientific physical refining and totally stainless steel tank refining. Palm kernel oil is non-drying oil with low gum content, which is suitable for physical refining. Fatty acid composes of 45%-51% lauric acid and 13%-25% cardamom acid. Palm kernel oil contains soap grade and food grade.The process of Palm kernel oil refinery is to refine the crude edible oil, to remove gossypol, protein, phospholipid, grume, moisture and other impurities, in order to reach the purchase of food and storage.The process of palm kernel oil refinery includes mechanical refinery method, chemical refinery method and physical refinery process refinery process.

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

Palm kernel oil refinery

Products

palm oil mill plant projects

Palm Oil Extraction FAQ

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines

recommend products