Modern palm oil processing method

There are various palm oil processing methods, which can be divided into traditional palm oil processing methods and modern palm oil processing methods according to output and complexity. Modern palm oil processing methods are further divided into small-scale palm oil processing plants, medium-scale palm oil processing plants and large-scale industrial palm oil processing plants according to scale.

Generally, processing units that process no more than 5 tons of fresh fruit bunches (FFBs) per hour are considered small-scale palm oil processing plants. Units that process 6 to 10 tons of FFBs per hour are considered medium-scale palm oil processing plants, while palm oil processing plants that process more than 10 tons of FFBs per hour are considered large-scale.

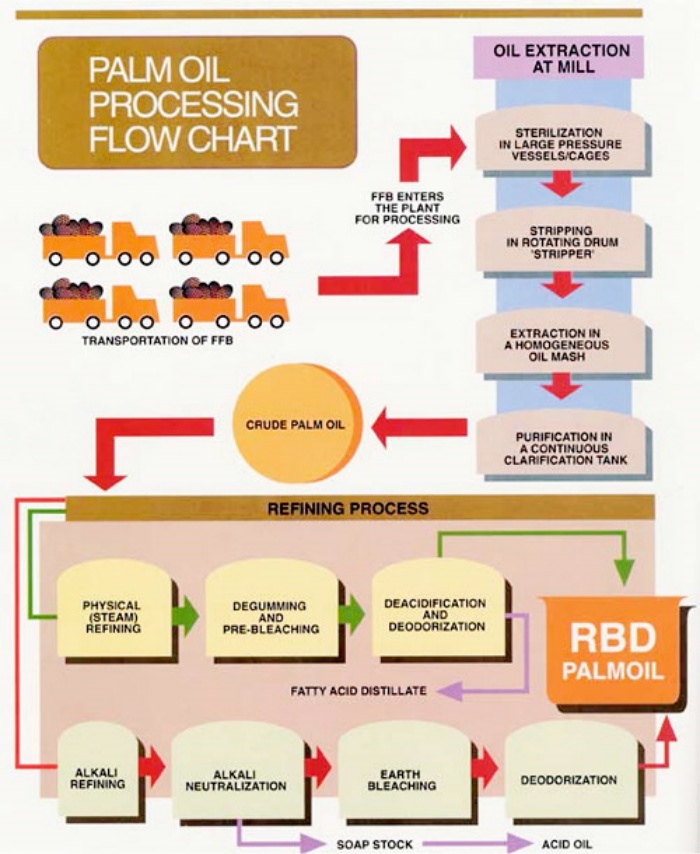

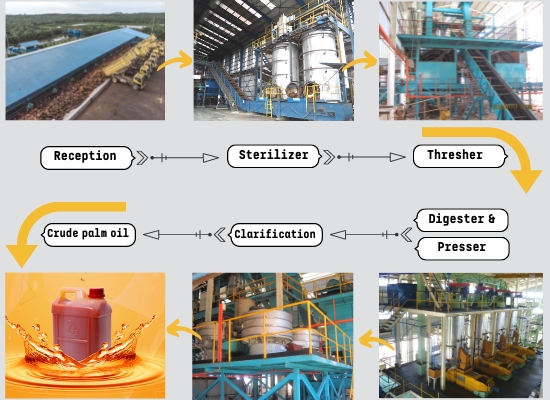

Palm oil processing process

Palm oil processing process

While there is extensive literature on traditional palm oil processing methods and medium and large-scale palm oil processing plants, there is less information available on modern small-scale palm oil processing plants. Therefore, the primary objective of this article is to provide a detailed description of the various process flows involved in modern small-scale palm oil processing plants and the types of machinery required.

Before going into the types of machinery involved in the modern small-scale palm oil processing plants, let me first introduce the processes involved for you. Typically, after fruit bunches are harvested from palm oil plantations, they are transported to the small-scale palm oil processing plants. At the small-scale palm oil processing plants, the fresh fruit bunches (FFBs) are first weighed and then transported to the sterilization area for sterilization. After sterilization, the next step is stripping and threshing to separate the fruit from the bunches. The empty bunches are discarded and used as fuel to power the sterilization furnaces. The separated fruit is then conveyed to the digester, where the threshed fruit is digested into pulp. Next, the pulp is conveyed to the palm oil pressing machine, where crude red palm oil is extracted and sent to the clarifiers for sedimentation and purification. The resulting fiber and palm kernel mixture enters the palm kernel processing system. The separated palm kernels are crushed and pressed before being further processed into palm kernel oil, which is used in various industries such as food, cosmetics, and biofuels.

Next, I will take Henan Glory Company—a manufacturer specializing in the design and manufacture of complete palm oil processing plants with various capacities—as an example to introduce you to introduce three different types of modern small-scale palm oil processing plants.

Type 1. 1T/H Free-Installation Small-Scale Palm Oil Processing Plant

Perfect for startups or small-scale palm oil producers, this free-installation small-scale palm oil processing plant requires minimal installation and setup. It integrates essential steps—sterilization, threshing, digesting, pressing, filtering and drying—into a unified system that is easy to operate and maintain. Included equipment is a hot water tank, three sterilization tanks, a palm fruit thresher, a modified double screw palm oil press machine, a standard double screw palm oil press machine, an oil clarification tank, a vibrating screen, a plate and frame filter, and a vacuum drying system. It is a practical and affordable solution for processing up to 1ton of Fresh Fruit Bunches (FFB) per hour.

1T/H free-installation small-scale palm oil processing plant

1T/H free-installation small-scale palm oil processing plant

Type 2. 1-2T/H Cost-Effective Small-Scale Palm Oil Processing Plant

Designed for growing businesses, this cost-effective small-scale palm oil processing plant incorporates advanced sterilization using steam, significantly reducing palm oil processing time and improving overall efficiency. It delivers oil quality comparable to large-scale palm oil processing plants while remaining accessible and efficient for medium-sized palm oil processing plants. Compared with the free-installation small-scale palm oil processing plant, it has not water tank and modified double-screw palm oil press machine, and more a digesting tank and a double-screw palm oil press machine. Suitable for 1-2tons FFB per hour, this cost-effective small-scale palm oil processing plant is robust, energy-efficient, and easily adaptable to different processing environments.

1-2T/H cost-effective small-scale palm oil processing plant

1-2T/H cost-effective small-scale palm oil processing plant

Type 3. 5T/H Fully-Automatic Small-Scale Palm Oil Processing Plant

For small-scale palm oil producers aiming for high output with minimal manual intervention, this 5t/h fully-automatic small-scale palm oil processing plant is industrial-grade automation. It features a vertical steam sterilizer that not only handles automatic feeding and discharging but also eliminates manual labor. Combined with a scraper conveyor for continuous fruit bunch handling, the small-scale palm oil processing plant enables uninterrupted 24/7 operation.

5T/H fully-automatic small-scale palm oil processing plant

5T/H fully-automatic small-scale palm oil processing plant

Henan Glory is a professional manufacturer of modern palm oil processing equipment. We provide comprehensive solutions, from plant design and machinery supply to installation guidance. Whether you need a complete palm oil processing plant or a specific machine like a palm oil expeller or refining equipment, we have various models to meet your needs.

For more information on our modern small-scale palm oil processing plants, palm oil production machinery, or refining equipment, please get in touch with us. Our expert team is ready to provide you with a personalized consultation.

NEXT:Origin of oil palm

NEXT:Origin of oil palm

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How lucrative is the palm oil business, and is it worth investing in?

-

-

How much it will cost to set up a small scale palm oil mill in Nigeria?

-

-

6 Reasons Why Palm Kernel Oil Production in Nigeria is a Smart Investment

-

How can I get palm kernel oil in a palm kernel oil processing plant?

-

-

Why you can invest in palm oil processing business in Ghana?

-

What are reasons that affect the oil yield of palm oil press?

-

How much does it cost to setup a mini palm oil refining plant?

-

2tph Palm Oil and Palm Kernel Oil Processing Machines Project in Nigeria

-

-

-

1tph palm oil pressing machines successfully installed in Lagos, Nigeria

-

-

-

-

500kg/h palm oil and palm kernel oil processing plant project in Ghana

-

-

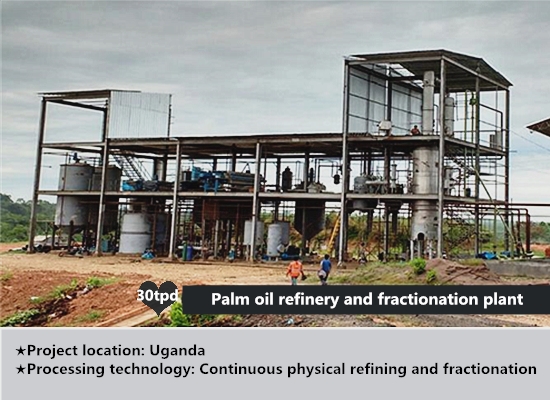

30tpd palm oil refinery and fractionation plant project successfully installed in Uganda