How much does it cost to setup a mini palm oil refining plant?

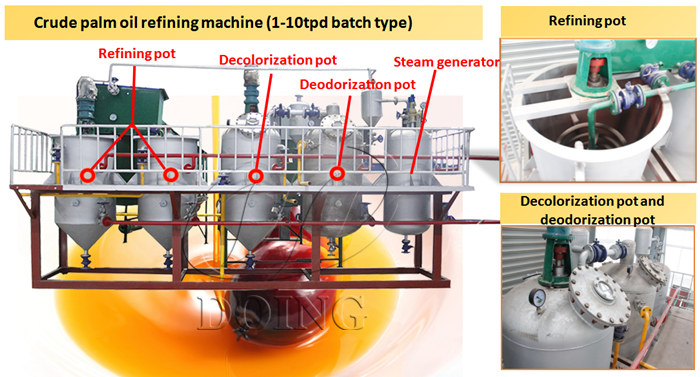

It is a good choice to setup a mini palm oil refining plant if you have small processing capacity and limited budget. Generally for mini or small palm oil refineries, our refining process is batch refining. Speaking of cost to setup a mini palm oil refining plant, the cost of batch refining equipment depends on the heating mode of the equipment and the processing tonnage. The heating methods can be divided into electric heating refining and heat transfer oil refining.

Batch type palm oil refining machine

Batch type palm oil refining machine

The cost of electric heating refining plant in a mini palm oil refining plant is between $15000 and $40000 according to the configuration. Refining by electric heating mainly relies on electric power to provide heat source for the equipment. The processing capacity of our electric heating refining equipment mainly includes 0.5TPD, 1TPD and 2TPD. The general standard electric heating and refining configuration includes refining pot, bleaching pot, deodorization pot, steam generator, vacuum separator, hot water alkali water tank, clay tank, oil pump, installation materials, power distribution system, etc. Electric heating refining has the advantages of low cost and small floor area. At the same time, it also has the disadvantage of large power consumption.

Electric heating refining plant

Electric heating refining plant

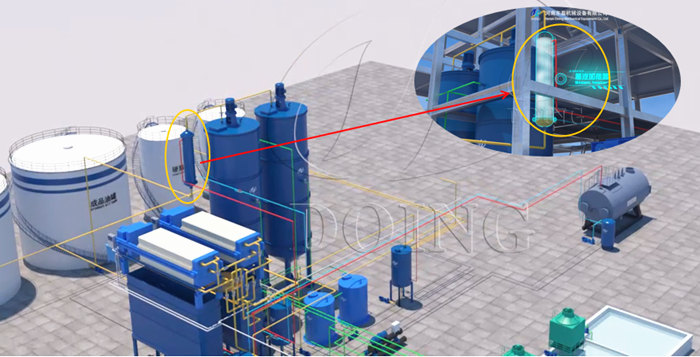

The cost of heat transfer oil refining plant in a mini palm oil refining plant varies from $60000 to $150000 depending on the configuration. The heat source for heat transfer oil refining is mainly provided by the heat transfer oil furnace. If you are in an area where the power supply is not stable enough. For our processing capacity of 1-10TPD, we also have heat transfer oil refining system. The heat transfer oil is heated by the heat transfer oil furnace and then heated by the heat transfer coil to provide heat source for different refining sections. The standard configuration mainly includes two refining pans, decolorizing pans, deodorizing pans, alkali liquor tanks, clay tanks, vane filters, steam boilers, vacuum systems, cooling towers, heat transfer oil systems, etc. What is more, in order to meet the needs of production and ensure the quality of refining, we will use 304 stainless steel in the deodorization section.

Heat transfer oil refining plant

Heat transfer oil refining plant

Whether a mini palm oil refining plant is heat transfer oil refining or electric heating refining, our equipment includes four sections, degumming, deacidification, decolorization and deodorization. The cost to setup a mini palm oil refining plant needs to be further communicated with you before final confirmation. If you have any need to setup a mini palm oil refining plant, you can contact us at any time.

PREV:What are reasons that affect the oil yield of palm oil press?

PREV:What are reasons that affect the oil yield of palm oil press?

NEXT:How do I start a palm kernel oil processing plant in Liberia?

NEXT:How do I start a palm kernel oil processing plant in Liberia?

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How lucrative is the palm oil business, and is it worth investing in?

-

-

How much it will cost to set up a small scale palm oil mill in Nigeria?

-

-

6 Reasons Why Palm Kernel Oil Production in Nigeria is a Smart Investment

-

How can I get palm kernel oil in a palm kernel oil processing plant?

-

-

Why you can invest in palm oil processing business in Ghana?

-

What are reasons that affect the oil yield of palm oil press?

-

How much does it cost to setup a mini palm oil refining plant?

-

2tph Palm Oil and Palm Kernel Oil Processing Machines Project in Nigeria

-

-

-

1tph palm oil pressing machines successfully installed in Lagos, Nigeria

-

-

-

-

500kg/h palm oil and palm kernel oil processing plant project in Ghana

-

-

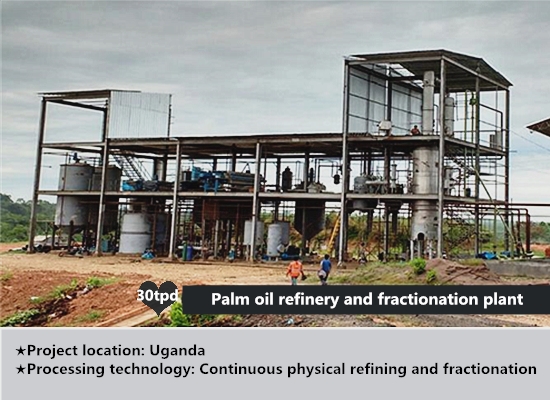

30tpd palm oil refinery and fractionation plant project successfully installed in Uganda