What is the process of palm kernel oil extraction?

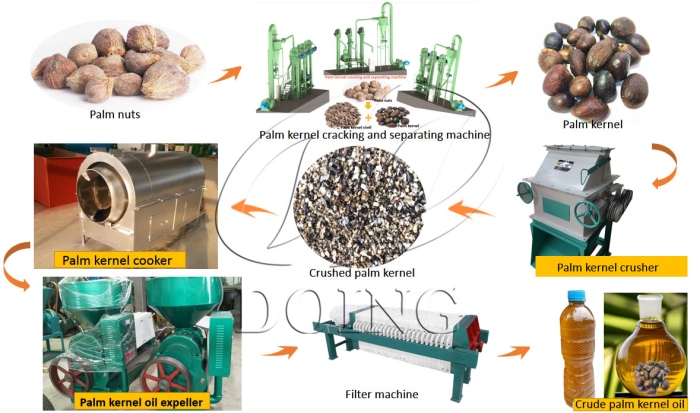

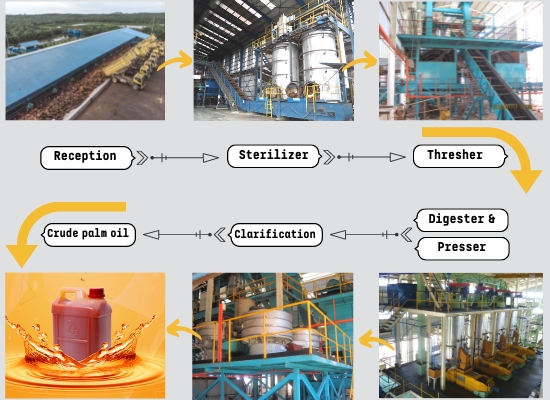

The complete process of palm kernel oil extraction include fiber separation, palm kernel cracker and shell separation system, crusher, cooker, palm kernel oil press machine and filteration. Specific configuration could be changed based on your actual requirements and needs. In this article, we will discuss the mature production process of palm kernel oil extraction and the equipment used in each step.

Complete process of palm kernel oil extraction

Complete process of palm kernel oil extraction

Step 1: Fiber separation

The first step in palm kernel oil extraction is fiber separation. The fiber separator is used to remove the fibers from the shell of palm kernels, making it easier for subsequent peeling and pressing. The remaining fibers can be used for fuel or feed.

Step 2: Palm kernel cracker and shell separation system

Palm kernel cracker and shell separation system

Palm kernel cracker and shell separation system

The palm kernel cracker and shell separation system includes a magnetic separator, nuclear grading sieve, shell peeling machine, air separation column, and shakelon. The magnetic separator removes metal impurities, while the nuclear grading sieve divides palm kernels into evenly sized ones. The shell peeling machine uses impact and friction to break fruit kernels. The air separation column allows palm kernels to fall into the hopper of mobile phone palm kernels based on the weight and force area of palm kernels and shells. The separation rate can reach around 95% through a bucket elevator. The shakelon uses wind power to create a whirlwind shape on the shell, preventing it from drifting around when it comes out.

Step 3: Crusher

Crusher

Crusher

The crusher is for breaking the palm kernels, which is more beneficial for later steaming, frying, and squeezing to extract palm kernel oil.

Step 4: Cooker

Cooker

Cooker

The cooker is used to adjust the moisture content and palm kernel temperature, making it more conducive to oil production.

Step 5: Palm kernel oil press machine

Palm kernel oil press machine

Palm kernel oil press machine

The oil press is the most critical step in palm kernel oil extraction. Our oil press is mainly 500 kilograms per hour, using advanced technology and built by professional engineers. It has the characteristics of high oil yield, durability, and high efficiency.

Step 6: Filteration

Plate and frame filter

Plate and frame filter

In the filtration stage, we mainly use a plate and frame filter, which is used to remove impurities in the oil and some moisture.

Each process in palm kernel oil extraction is essential to get more and better palm kernel oil. If you have budget issues, you can consider simple equipment configuration. In a word, you can also tell us your budget and specific needs, and our professional engineers and sales team will provide customized services for you. It can save you production costs while ensuring your production efficiency. Contact us for more information.

PREV:How much it will cost to set up a small scale palm oil mill in Nigeria?

PREV:How much it will cost to set up a small scale palm oil mill in Nigeria?

NEXT:6 Reasons Why Palm Kernel Oil Production in Nigeria is a Smart Investment

NEXT:6 Reasons Why Palm Kernel Oil Production in Nigeria is a Smart Investment

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How lucrative is the palm oil business, and is it worth investing in?

-

-

How much it will cost to set up a small scale palm oil mill in Nigeria?

-

-

6 Reasons Why Palm Kernel Oil Production in Nigeria is a Smart Investment

-

How can I get palm kernel oil in a palm kernel oil processing plant?

-

-

Why you can invest in palm oil processing business in Ghana?

-

What are reasons that affect the oil yield of palm oil press?

-

How much does it cost to setup a mini palm oil refining plant?

-

2tph Palm Oil and Palm Kernel Oil Processing Machines Project in Nigeria

-

-

-

1tph palm oil pressing machines successfully installed in Lagos, Nigeria

-

-

-

-

500kg/h palm oil and palm kernel oil processing plant project in Ghana

-

-

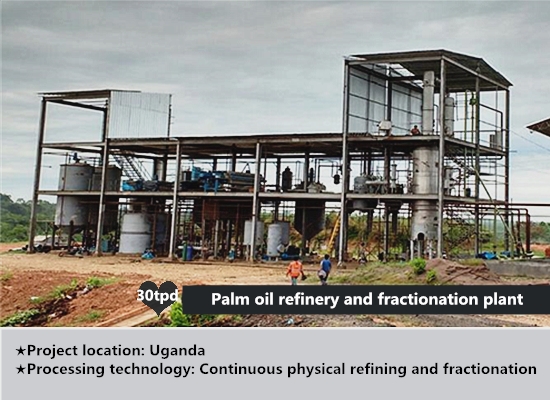

30tpd palm oil refinery and fractionation plant project successfully installed in Uganda