Why is it important to choose suitable palm fruit digester?

Generally speaking, a complete palm oil processing mill includes process of sterilizing, threshing, digesting, pressing, oil clarification, filtering, drying and storing. Each section has a different function and uses different equipment, but each equipment is particularly important in the whole palm oil production process. Today, we mainly introduce the importance of palm fruit digester.

Palm fruit digester is placed behind the palm fruit threshing machine, in front of the palm oil pressing machine. So what is the palm oil digester? How does palm fruit digester machine work?

Palm fruit digester machine

Palm fruit digester machine

The palm fruit digester machine design includes a heated cylindrical container equipped with a central rotating rod carrying very thick reamers with a long service life. It is used to mash sterilized palm fruits in palm oil production process. It is also known as palm oil digester, palm fruit mash machine, or digester screw press. After digesting process, the overall palm oil extraction efficiency is greatly improved.

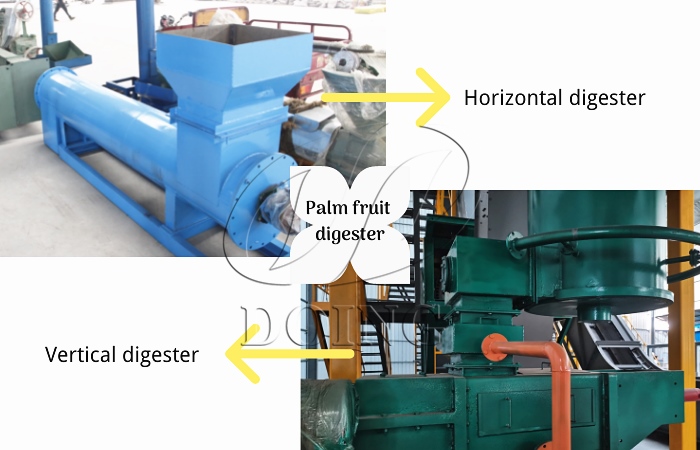

Palm fruit digester machine has two types: horizontal digester and vertical digester.With the upgrading of technology, the vertical type is more efficient than the horizontal type. At present, all the palm oil mill projects designed by Doing Company are equipped with vertical palm fruit digester machine.

Horizontal palm fruit digester and vertical palm fruit digester

Horizontal palm fruit digester and vertical palm fruit digester

With the deepening of understanding of palm fruit digester machine, you may be wondering how does palm fruit digester work? Please continue reading.

The palm fruit digetser machine achieves the purpose of obtaining more oil by mashing palm fruit to palm pulp. The digester has built-in multi-layer reamers. While the reamer rotates and breaks, the heating coil pipes steam into the digester. The temperature can reach 90-95℃, which also helps the fruit soften, mash and press more oil. The digester runs optimally when it is full or at least three quarters full. It takes about 15 minutes for the palm oil digester machine to process a single batch from the thresher. After about 15 minutes in the digester, the closing chute opens, and the fruit moves to the double screw pressing machine. By the way, it is very important to match the capacity of the double screw palm oil pressing machine to the palm fruit digester machine.

Vertical palm fruit digester machine

Vertical palm fruit digester machine

Palm fruit digester machine can not only reduce the residual oil rate, but also extend the service life of the palm oil pressing machine. It is very important for the quality of palm oil and the efficiency of palm oil production. If you are interested in palm fruit digester machine or other palm oil processing machine, please contact us without hesitation!

As an experienced and reliable palm oil processing machine manufacturer and supplier, we have our own patents, we design and produce the machine according your need. What's more, we have our own factory and our engineers have about 20 years project experience. Just tell us your needs and we can help you make the best business plan with tailor-made palm oil factory layout design and cost-effective equipment.

PREV:What factors should be paid attention to when buying palm kernel oil processing machine?

PREV:What factors should be paid attention to when buying palm kernel oil processing machine?

NEXT:What is the features of small scale palm oil refinery plant?

NEXT:What is the features of small scale palm oil refinery plant?

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines