Palm oil mill process flow diagram introduction

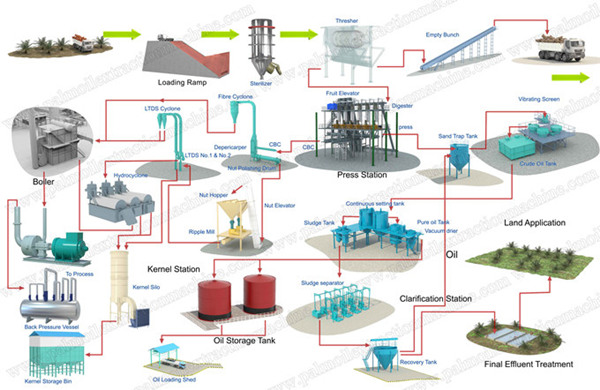

Palm oil mill process flow diagram mainly uses the expression of graphical symbols, which can clearly express the structure of the whole palm oil mill and the operation process of the palm oil mill process. The entire palm oil mill process involves the reception of fresh fruit bunches from the plantations, sterilizing and threshing of the bunches to free the palm fruit, mashing the fruit and pressing out the crude palm oil. The crude oil is further treated to purify and dry it for storage and export.

Palm oil mill process flow diagram (click here to view larger)

Palm oil mill process flow diagram (click here to view larger)

Palm oil mill process flow diagram main stations:

| No | Main section | Main machine |

| 1 | Fresh palm fruit bunch reception section | Loading ramp |

| 2 | Sterilization section | Sterilization tank |

| 3 | Threshing section | Threshing Machine Platform |

| 4 | Digesting & Pressingsection | Digester & Screw presser |

| 5 | Oilclarification section | ClarificationTank |

| 6 | Fiber separation section | Polishing drun |

| 7 | Palm kernel recovery section | (1)Palm nut storage tank (2)Polishing drum (3)Nut grading screen (4) Palm nut Ripple mill (5)Separating column system (6)hydro cyclone equipment (7)Palm kernel drying bunker (8)Dry Palm kernel final storage warehouse |

| 8 | Nutsheller | |

| 9 | Engine room | Diesel generator |

| 10 | Boiler house | Boiler |

| 11 | Water treatment | |

| 11 | Effluent Treatment Plant |

Palm oil mill process flow diagram introduction:

1.Fresh palm fruit bunch reception section:

Palm fruit reception station

Palm fruit reception station

Fresh palm fruit bunch reception :

FFB means fresh palm fruit bunch which can be harvested all the year round. After cutting from palm trees, fresh palm fruit bunch must be processed within 2days. Or the acid value will be high and affect the final palm oil quality.

2.Sterilizing Station

Palm fruit sterilization machine

Palm fruit sterilization machine

The FFB are discharged into the loading ramp, then transported to sterilizer for sterilization. It uses high temperature to softening the fruit and kill the bacteria, this will increase the moisture content of fruit and separate the fruits easily, so finally it will easy to get oil and separate palm kernel, also avoid the raising of free fatty acid. From picking to sterilization, the time shall not over 24 hours.

3.Threshing Station

Palm fruit threshing machine

Palm fruit threshing machine

In the sterilizing process, the palm fruits are softening, through the threshing and screening of thresher to separate the palm fruits and empty fruit bunches(EFB).

Empty Bunch Conveyor

The EFB are stored to be use as fuel or fertilizer, also can be used for other functions.

Fruit Elevator will conveying the threshed palm fruit(from Under Thresher Conveyor) to next step of Palm fruit pressing station.

4.Digesting & Pressing Station

Palm fruit digesting and pressing machine

Palm fruit digesting and pressing machine

Transport the palm fruits to the digester to mixed and cooked again to separate the palm pulp and nut, then use double screw hydraulic palm oil presser to get crude palm oil, which improved the production efficiency greatly.

5.Oil clarification station

Crude palm oil clarification machine

Crude palm oil clarification machine

Machine-pressed crude palm oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment. The oil and the sludge taken out separated (by 90% pure oil) is taken out of the oil containing 45%-55% of the water, sludge and other things.

6.Oil Tank and Oil Loading Shed

Oil tank in palm oil mill

Oil tank in palm oil mill

Store the crude palm oil and ready to load the oil to other places.

7.Depericarping Station

The pressed palm fiber cake gets into the cake breaker then get into the winnowing system to separate the fiber and nut.

8.Kernel Recovery System

Palm kernel recovery machine

Palm kernel recovery machine

Then nut will be crushed to get shell and kernel. Through winnowing system and washing system to separate the shell and kernel. The shell can be used as fuel for boiler, the kernel will be dried for storage and sell to others or next processed into palm kernel oil by another plant(palm kernel processing plant ).

(1)Palm nut storage tank: used for storage the palm kernel

(2)Polishing drum: Used for polishing the palm nut and remove the residual fibre to get clean palm nut.

(3)Nut grading screen:classify palm nuts into different grades

(4)Ripple mill: Used for cracking the palm nut , cracking the hard shell of the palm nut and get the mixtures of palm kernel and shell.

(5)Separating column system &hydro cyclone equipment:separate the kernel from the shell

(6)Palm kernel drying bunker: drying finally palm kernels:finally the dryed palm kernels can be processed further via palm kernel oil expeller or directly sell to others.

(7)Dry Palm kernel final storage warehouse: Used for storage the dryed palm kernel.

Other Assistant Equipments of Palm Oil Mill

9.Boiler House:

10.Power House

11.Water Supply and Treatment (Including boiler water treatment)

12.Effluent Treatment Plant

The above is the mainly introduction of palm oil mill (suitable for capacity above 15tph). Any question about palm oil mill process flow chart diagram and any capacity palm oil processing machine , please feel free to contact Henan Doing Company. You will get more thank you think.

PREV:What factors affect palm oil yield?

PREV:What factors affect palm oil yield?

NEXT:What are the featured advantages of small scale palm oil refining machine?

NEXT:What are the featured advantages of small scale palm oil refining machine?

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines