Why Nigeria palm oil producers prefer modular palm oil production system?

Nigeria is one of the largest palm oil producers in Africa, and the palm oil industry plays a critical role in the nation's economy. With the growing demand for palm oil both domestically and internationally, Nigeria palm oil producers are continuously looking for ways to optimize their palm oil production processes, improve efficiency and enhance the quality of palm oil. The modular palm oil production system launched by Henan Glory Company has become one of the solutions that has attracted much attention. This article explores the reasons why Nigerian palm oil producers prefer modular palm oil production system.

1. Flexibility and Scalability

One of the most compelling reasons why Nigerian palm oil producers prefer modular palm oil production system is their flexibility and scalability. Modular palm oil production system is designed with adaptability in mind, allowing palm oil producers to scale up or down their palm oil production capacity based on market demand, available resources and seasonal fluctuations.

For many Nigerian palm oil producers, particularly those in rural areas, starting with a small-scale palm oil production operation and gradually expanding as the business grows is an ideal solution. Modular palm oil production system allow palm oil producers to start with a compact setup and add additional modules as their production needs increase. This ensures that they don’t have to make significant upfront investments but can still meet growing demand efficiently.

2. Cost-Effective Investment

Capital investment in palm oil production facilities can be a significant barrier for many Nigerian palm oil producers, especially small to medium-scale businesses. Modular palm oil production system offers a more cost-effective solution by reducing the need for large-scale infrastructure and high initial capital expenditures.

The modular palm oil production system introduced by Henan Glory allows Nigeria palm oil producers to invest in smaller, more affordable palm oil production equipment, including palm fruit sterilization equipment, palm fruit threshing equipment, palm oil pressing equipment, palm fruit digesting equipment after the palm oil pressing equipment is converted, palm oil filtering equipment and vacuum drying equipment, which can be continuously expanded as the business grows. This reduces financial risk while still providing the potential for future profitability. The modular palm oil production system is not only cost-effective in terms of initial investment, but also reduces operating costs due to energy-saving design and minimal waste in the palm oil production process.

The modular palm oil production system produced by Henan Glory Company

The modular palm oil production system produced by Henan Glory Company

3. Efficiency and Improved Oil Quality

A key consideration for Nigerian palm oil producers is the efficiency of the palm oil production process. Traditional palm oil production involves labor-intensive processes that are not only time-consuming but also inefficient in terms of yield per hectare. However, modular palm oil production system use advanced technology to streamline operations from start to finish. The modular palm oil production system integrate automated processes such as palm fruit sterilization, digestion, pressing and clarification, greatly reducing manual intervention and thus increasing productivity. With modular palm oil production system, Nigerian palm oil producer can process large quantities of palm fruit in a shorter time, ensuring higher yields without compromising quality.

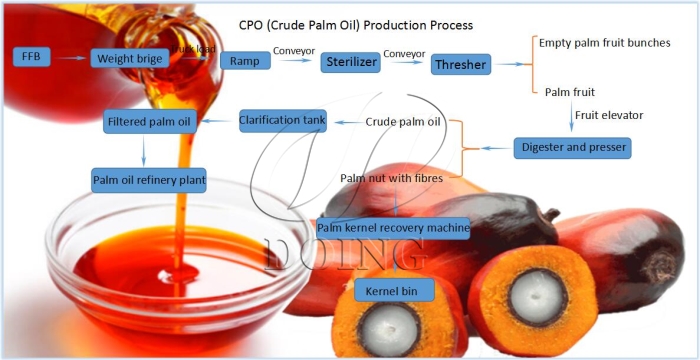

The palm oil production process

The palm oil production process

4. Reduced Environmental Impact

The environmental impact of palm oil production is an ongoing concern, and modular palm oil production system help address some of these challenges. With their energy-efficient design and waste minimization technologies, modular palm oil production system contributes to more sustainable production practices.

By reducing energy consumption and making use of renewable energy sources, such as biogas from palm oil mill effluent (POME), modular palm oil production system is not only beneficial for the environment but also help Nigeria palm oil producers lower their energy costs. Additionally, the efficient use of raw materials reduces waste and ensures that more of the palm fruit is processed into usable oil, which enhances the sustainability of the operation.

5. Easy Installation and Maintenance

For Nigeria palm oil producers, particularly those operating in remote locations, the ease of installation and maintenance is a significant advantage of modular palm oil production system. Unlike traditional, large-scale palm oil production system that requires extensive infrastructure and complex setup, modular palm oil production system is simpler to install, with a reduced need for specialized personnel or significant downtime during the installation phase.

Maintenance is also easier with modular palm oil production system, as individual components can be serviced or replaced without interrupting the entire palm oil production process. This minimizes downtime and helps Nigeria palm oil producers maintain a steady output, which is vital for keeping production on schedule and meeting market demand.

6. Support for Local Farmers and Small Producers

The modular palm oil production system launched by Henan Glory Company has a capacity of 1 ton/hour, providing significant support to local farmers and small-scale palm oil producers by enabling them to process palm fruit locally, rather than relying on larger centralized palm oil mills. This empowers small palm oil producers and cooperatives by offering a more sustainable and decentralized approach to palm oil production.

1TPH modular palm oil production system

1TPH modular palm oil production system

7. Adaptability to Local Conditions

Nigeria’s palm oil production is heavily influenced by the diverse and sometimes challenging local conditions. Modular palm oil production system is designed to be highly adaptable to these conditions, making them an ideal choice for palm oil producers in various regions of Nigeria.

Whether dealing with seasonal variations, unpredictable weather patterns or varying levels of palm fruit availability, modular palm oil production system can be tailored to suit local conditions. This makes them a reliable option for producers who need a production system that can cope with the unique challenges of the Nigerian palm oil industry.

8. Technical Support and After-Sales Services

When investing in palm oil production machinery, the quality of technical support and after-sales service is crucial. It is worth mentioning that Henan Glory Oils & Fats Engineering Co., Ltd. can provide comprehensive technical support for modular palm oil production system, including installation, training and maintenance services. Their expert team ensures that palm oil producers can operate their modular palm oil production systems smoothly and resolve any issues promptly. Additionally, the modular palm oil production system is backed by high-quality customer service, which ensures that Nigerian palm oil producers can count on Henan Glory for spare parts, upgrades, and assistance whenever needed.

Technical support and after-sales services

Technical support and after-sales services

In summary, the modular palm oil production system offers many benefits to Nigerian palm oil producers. As the demand for palm oil continues to grow, the modular palm oil production system provides an ideal solution for Nigerian palm oil producers who want to expand their operations without incurring large costs. By investing in a modular palm oil production system, Nigerian palm oil producers can increase their palm oil production capacity, improve the quality of palm oil products, and meet the needs of local and international markets. If you are interested in this, please contact Henan Glory Company today to get detailed information on the modular palm oil production system!

PREV:Three Small Machines That Double Your Palm Oil Production: Low-Cost Upgrade!

PREV:Three Small Machines That Double Your Palm Oil Production: Low-Cost Upgrade!

NEXT:What is the working principle of vacuum dryer in palm oil mill?

NEXT:What is the working principle of vacuum dryer in palm oil mill?

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines