Henan Doing Company palm oil processing machine main features

The picture of palm fruit bunch and palm fruit

In China there is no large-scale cultivation of palm, so the domestic palm fruit oil processing machine technology is relatively weak, the Division I after years of research, the palm oil processing machine has been fully mastered. Henan Doing Company palm oil processing machine technology is mature, has been exported to all around the world.

Henan Doing Company has got highly recognized by customers in the palm fruit oil processing , palm kernel oil extraction, cooking oil extraction, cooking oil solvent extraction, palm oil refining, fractionation and other fields .

Henan Doing Company palm oil processing machine main features:

1, Low environment pollution palm oil processing machine.

2, Palm fruit oil press machine adopts double screw continuous discharging, greatly improving the production efficiency;

3, The use of diesel generator and steam turbine generator is more environmental protection and energy saving, electricity power for production and life.

Leave A Message

If you want to know more information about Henan Doing Company palm oil processing machine main features . pls kindly leave your phone number, We will back to you ASAP once we got your message.

-

-

How much it will cost to set up a small scale palm oil mill in Nigeria?

-

-

6 Reasons Why Palm Kernel Oil Production in Nigeria is a Smart Investment

-

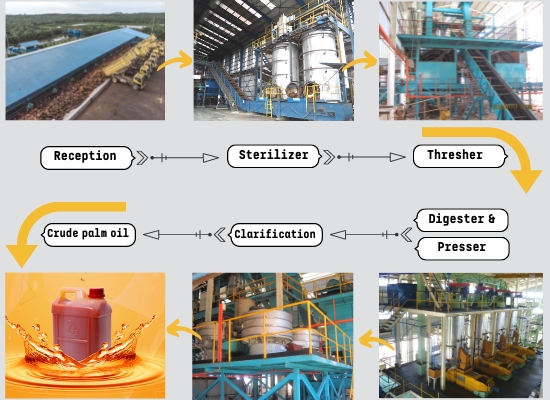

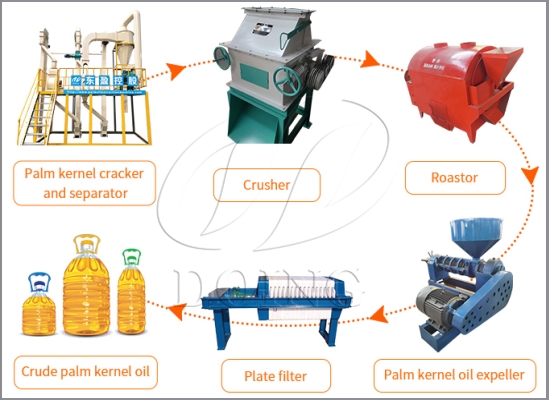

How can I get palm kernel oil in a palm kernel oil processing plant?

-

-

Why you can invest in palm oil processing business in Ghana?

-

What are reasons that affect the oil yield of palm oil press?

-

How much does it cost to setup a mini palm oil refining plant?

-

How do I start a palm kernel oil processing plant in Liberia?

-

2tph Palm Oil and Palm Kernel Oil Processing Machines Project in Nigeria

-

-

-

1tph palm oil pressing machines successfully installed in Lagos, Nigeria

-

-

-

-

500kg/h palm oil and palm kernel oil processing plant project in Ghana

-

-

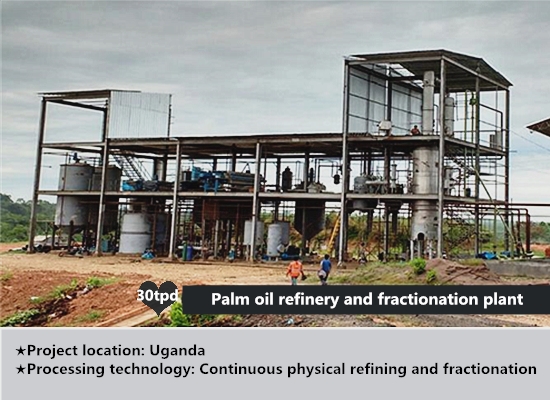

30tpd palm oil refinery and fractionation plant project successfully installed in Uganda