Modern palm oil processing method

Generally, processing units handling up to 2 tones of fresh fruit bunches (FFB) per hour are considered to be small-scale. Installations that process between 2 and 8 tones FFB per hour are termed medium-scale, while large-scale redres to mills that process more that 10 tones per hour.

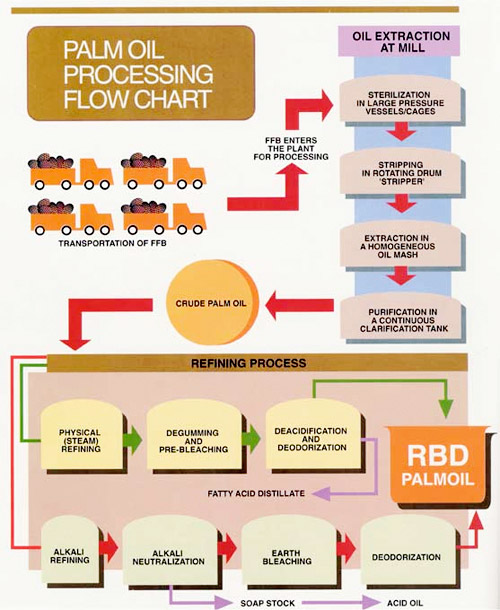

Palm oil processing flow chart:

Palm oil processing process

Machinery manufacturing is a recent development in the West Africa sub-region, and until recently it has not been possible to develop the sophisticated machines required to improve on traditional methods. Machinery manufacture in Africa must be carefully considered if progress is to be made in joining the rest of the industrialised world. Even now it is difficult to manufacture and sell bolts and coiled springs in the Central and West Africa sub-region. However, the manufacture of machines and combining them in the processing assemblies for small-scale rural industries is not within the scope of this publication. The main objective of this article is to provide a detailed description of the various processes involved in small-scale palm oil processing process, the tupe of machinery and equipment required, and their performance, energy and water consumption. The effect on the environment caused by waste and by-product uses is considered.

At the outset it must be stated that small-scale palm oil processing in the sub-region has systematically acquired sophistication, efficiency and reliability. It is agreed that traditional methods of extracting palm oil were inefficient and tedious for making oil for sale.

Generally women in the village are responsible for the processing and sale of fram produce. Small-scale agro-processing seems to hold the key to rural poverty reduction and the prolific oil palm tree provide the best raw material for starting rural industries.

Today small-scale processors who appreciate the value of using machines, are asking for them to be more sophisticated. Thus current demand for small-scale palm oil mills is shifting from simple stand-alone unit operational machines to a more integrated system which is easy to operate and maintain. Machinery manufacturers have responded with machines that combine several operations into one machine unit. The complete range of operation, oil drying and storage have been developed for small-scale processing applications. The processors can change and/or combine equipment to suit their purchasing power.

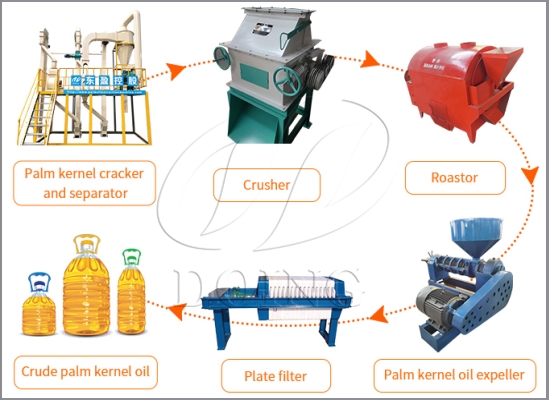

A by-product of palm oil extraction is the palm nut which, when cracked, yields a kernel containing a completely different kind of oil which can be used as a valuable substitute for cocoa butter. Unfortunately not many palm oil processors include palm kernel extraction at the same location. It is more usual that a completely different group undertakes palm kernel extraction.

To explain why this occurs, a description is included of how palm kernel oil is extracted and the relevant machinery and equipment needed, is indicated.

Henan Doing Machinery is a professional manufacturer of palm oil processing plant, we can supply you complete set palm oil processing plant with different capacities. Next i will introduce the small scale palm oil processing plant to you:

Modern palm oil processing methods introduce:

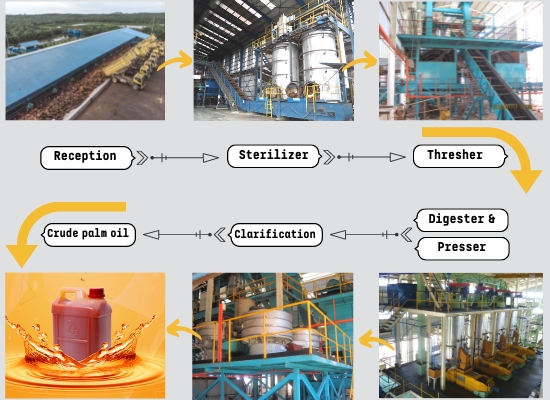

Before going into the technologies involved in the process of producing palm oil, we will talk about the processes involved. After harvesting the fruits in the oil plantation, the fruit bunches are moved to the palm oil mill. Here the fresh fruit bunches FFBs are weighed, and then the ffb will be transferred to the sterilization section where they are cooked. After sterilization the next step is stripping and threshing to separate the fruits from the husks or spent bunches (SFBs). The husks are then discarded and later used as fuel for firing the furnaces that power the sterilizer.The separated fruits are then transferred to the digester where the cooked fruits separated from the husks are mashed into a pulp. Hereafter the mash is transferred to the palm fruit oil pressing machine where the crude red palm oil is squeezed out and transferred into a clarifier for sedimentation.

The residue after digestion is a mixture of fiber and palm kernel nuts. This mixture is sent to a nut recovery system where the nuts are separated from the fiber. The nuts are dried and cracked to produce palm kernels.

The palm kernels are processed to produce palm kernel oil.

Modern small scale palm oil processing plant photos :

Main equipment in small scale palm oil processing plant

NEXT:Origin of oil palm

NEXT:Origin of oil palm

Leave A Message

If you want to know more information about Modern palm oil processing method . pls kindly leave your phone number, We will back to you ASAP once we got your message.

-

-

How much it will cost to set up a small scale palm oil mill in Nigeria?

-

-

6 Reasons Why Palm Kernel Oil Production in Nigeria is a Smart Investment

-

How can I get palm kernel oil in a palm kernel oil processing plant?

-

-

Why you can invest in palm oil processing business in Ghana?

-

What are reasons that affect the oil yield of palm oil press?

-

How much does it cost to setup a mini palm oil refining plant?

-

How do I start a palm kernel oil processing plant in Liberia?

-

2tph Palm Oil and Palm Kernel Oil Processing Machines Project in Nigeria

-

-

-

1tph palm oil pressing machines successfully installed in Lagos, Nigeria

-

-

-

-

500kg/h palm oil and palm kernel oil processing plant project in Ghana

-

-

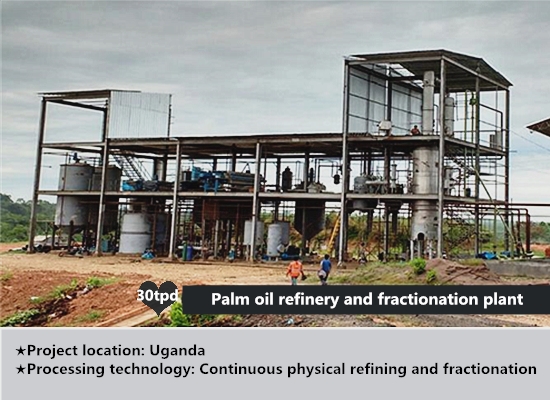

30tpd palm oil refinery and fractionation plant project successfully installed in Uganda