Palm oil physical refining process(1)

Palm oil physical refining process can be divided into 3 parts: pretreatment process, steam refining and deodorization process, and fractionation.

Palm oil physical refining process

The purpose of pretreatment is to remove impurities that are not removable by steam stripping or that would be degraded by treatment. These include, in varying amounts, materials such as phospholipids and trace metals.

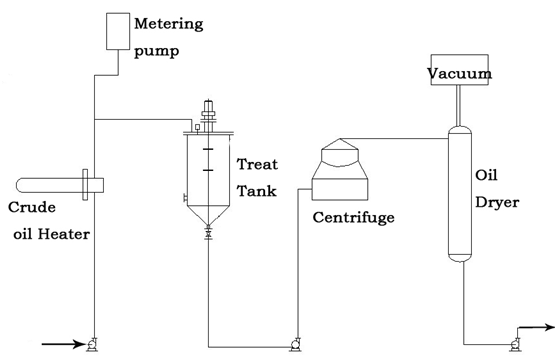

Crude palm oil is continuously pumped under automatic control, through the crude oil heater where it is heated to 190F. metering pumps feed concentrated phosphoric acid and demineralized hot water at controlled rates into a pipeline where they combine to form a dilute phosphoric acid solution.

The heated crude palm oil and dilute phosphoric acid are combined in a pipeline and delivered to the treat tank for thorough mixing.

The acid crude palm oil serves to react with the trace metals and inactivate them and also hydrate the phosphatides forming a second phase.

The oil-acid mixture is pumped to the centrifuge where the hydrated gums are separated from the oil by centrifugal force and discharged into waste water trap. The degummed oil passes to the oil dryer where disdegummed crude palm oil is removed under vacuum. The degummed crude palm oil is now ready for palm oil physical refining process.