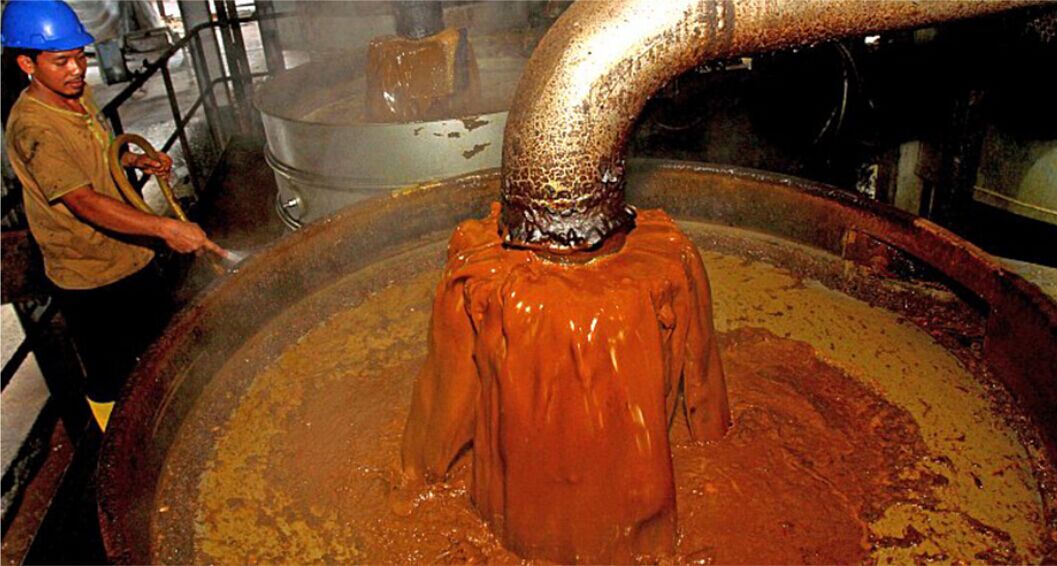

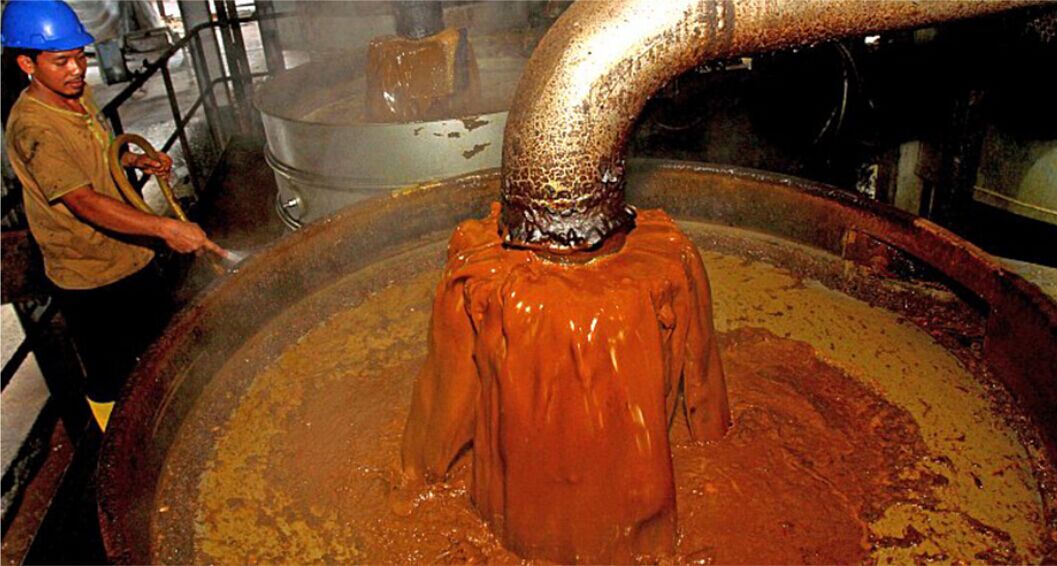

Total fat loss in palm oil refining plant

Total fat loss in palm oil refining plant deodorization section

Fats odor component amount is minimal, usually less than 0.01% by weight of oil. However, oil deodorization process is much greater than the actual value of the loss. This is because, in any case, the loss caused by the distillation depend upon the deodorization time, aeration rate, operating pressure and temperature, oil free fatty acids and other factors. In stripping deodorization process, a considerable amount of oil due to splashing in the stripping steam lost.

Therefore the total loss including the deodorization distillation loss and splashing loss, different oils, different devices and different operating conditions, which is not the same deodorization of total loss. In the advanced equipment and reasonable operating conditions, for free fatty acid content of less than 0.1% of fat, at an operating pressure of 0.4Kpa, a temperature of 230-270 degrees Celsius, which is generally the minimum loss deodorization 0.2% -0.4%, and then deodorized oil feedstock plus free fatty acid content of 1.05 to 1.2 times the total loss is the deodorization.

So, palm oil refining equipment selection is very important, and only choose the good equipment to make palm oil palm oil production process to reduce losses. You are welcome to ask any questions about the oil refining, oil production.

Fats odor component amount is minimal, usually less than 0.01% by weight of oil. However, oil deodorization process is much greater than the actual value of the loss. This is because, in any case, the loss caused by the distillation depend upon the deodorization time, aeration rate, operating pressure and temperature, oil free fatty acids and other factors. In stripping deodorization process, a considerable amount of oil due to splashing in the stripping steam lost.

Therefore the total loss including the deodorization distillation loss and splashing loss, different oils, different devices and different operating conditions, which is not the same deodorization of total loss. In the advanced equipment and reasonable operating conditions, for free fatty acid content of less than 0.1% of fat, at an operating pressure of 0.4Kpa, a temperature of 230-270 degrees Celsius, which is generally the minimum loss deodorization 0.2% -0.4%, and then deodorized oil feedstock plus free fatty acid content of 1.05 to 1.2 times the total loss is the deodorization.

So, palm oil refining equipment selection is very important, and only choose the good equipment to make palm oil palm oil production process to reduce losses. You are welcome to ask any questions about the oil refining, oil production.

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

contact us

Palm Oil Extraction FAQ

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines

Products