Some frequently asked questions about palm kernel oil refining

Question one: What is the process of refining palm kernel oil?

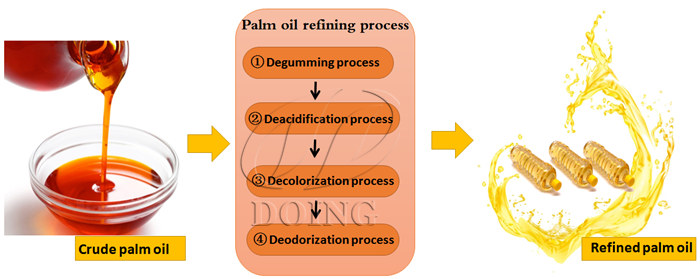

Palm kernel oil refining process is an extremely complex process. The palm kernel oil refining process includes degumming process, deacidification process, decolorization process and deodorization process.

Palm kernel oil refining process

Palm kernel oil refining process

Degumming

Add food grade phosphoric acid to the crude palm kernel oil to transform the non hydrated phospholipid into hydrated phospholipid, and add water to make the gum enter the aqueous phase to precipitate and remove.

Deacidification

Degummed palm kernel oil is added with food grade alkaline for acid-base neutralization reaction and removed by heating and natural sedimentation.

Decolorization

When the palm kernel oil is heated to a certain temperature, a certain amount of activated clay and activated carbon are added in the neutralized palm kernel oil, the pigment in the palm kernel oil will be physically adsorbed, so as to achieve the purpose of decolorization.

Deodorization

The deodorized palm kernel oil is heated to high temperature (250-260 ℃) and then enters into the deodorization tank. Under the negative pressure, a small amount of overheated steam is introduced into the palm kernel oil for stripping for a period of time, so as to achieve the purpose of deodorization.

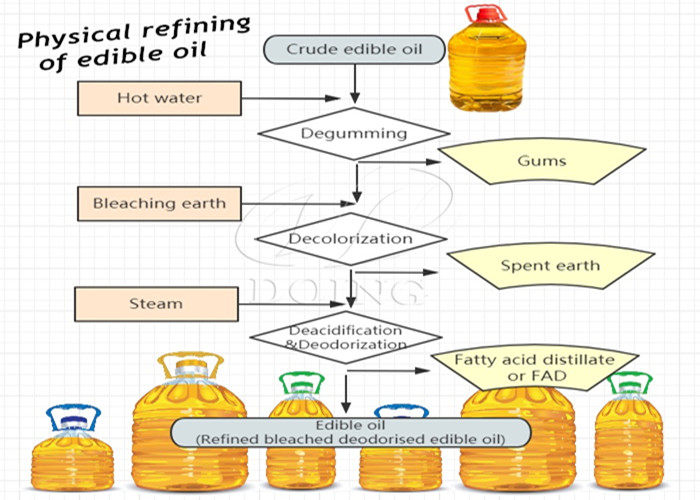

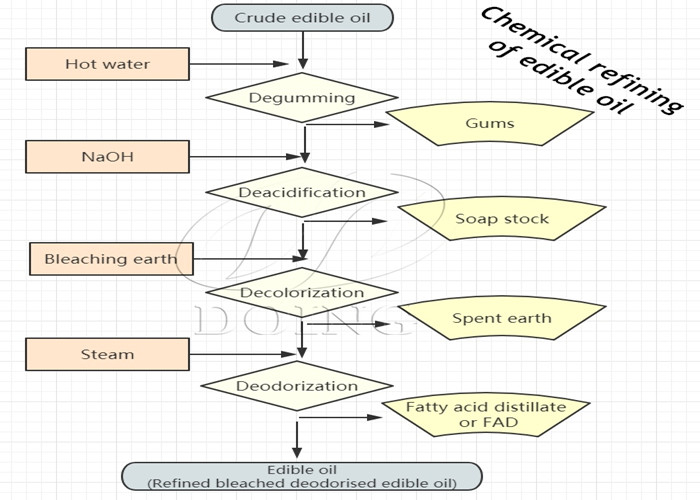

Question two: What is the difference between physical refining and chemical refining?

Physical refining process

Physical refining process

The main difference between physical refining and chemical refining of palm kernel oil lies in the way that how to remove FFA. Chemical refining removes the FFA in the deacidification section while physical refining removes the FFA in the deodorization section.

Chemical refining process

Chemical refining process

Comparatively speaking, physical refining of palm kernel oil is preferred in that it is a more economical process requiring less chemicals, producing less waste and giving higher oil yields.

Question three: Is refined palm kernel oil harmful to human body?

Refined palm kernel oil is crude oil produced from palm kernels, which is then refined and processed to remove impurities in the crude palm kernel oil so as to meet national sales standards. Therefore, refined palm kernel oil is not harmful to the human body.

Question four: How to choose the appropriate type of palm kernel oil refining equipment?

Henan Glory Company has three types of palm kernel oil refining equipment based on different processing volumes. Batch palm oil refining equipment is suitable for ≤20tpd. Semi-continuous palm oil refining equipment is applicable to 5-30tpd. Continuous palm oil refining equipment is suitable for 30TPD or more. You can choose according to your needs and budget.

Palm kernel oil refining equipment

Palm kernel oil refining equipment

We have been in the palm kernel oil refining equipment production industry for more than 10 years, we have lots of experience. At the same time, we also have our own branch in Nigeria. If you want to know more questions about palm kernel oil refining, you can come to our office in Nigeria for detailed discussions. The address is 19B Kudirat Abiola Way Olusosun Bus stop.

PREV:What is the fractionation of crude palm oil?

PREV:What is the fractionation of crude palm oil?

NEXT:What is the function of palm fruits threshing drum in palm oil mill?

NEXT:What is the function of palm fruits threshing drum in palm oil mill?

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines