What are the development trends and technological innovations in the palm oil processing industry?

In recent years, the growing global demand for sustainable and cost-effective edible oils has driven significant progress in the palm oil processing industry. As consumers become more aware of the importance of health and environmental impact, the palm oil processing industry has been forced to adapt and innovate to ensure palm oil processing efficiency and the quality of the final product. This article will explore the development trends and technological innovations in the palm oil processing industry.

1. Planting palm fruit trees sustainably:

There is a growing trend to establish palm plantations in a way that minimizes deforestation. This includes increasing the yield per unit area of palm plantations through genetic improvement and better agronomic practices, thereby reducing the land used for palm tree planting.

Large scale palm plantation

Large scale palm plantation

2. Improving palm oil processing efficiency:

The process of processing palm oil is changing by adopting more efficient technologies such as screw pressing. This method ensures higher oil recovery while minimizing damage to the oil's molecular structure, which is essential to maintaining its nutritional value. Among them, Henan Glory Company manufactures screw palm oil press machine suitable for this process, which are mainly divided into single screw palm oil press machine and double screw palm oil press machine. In addition, the single screw palm oil press machine also has motor and diesel models for people to choose from.

Two kinds of screw palm oil press machines

Two kinds of screw palm oil press machines

3. Improving palm oil processing waste management:

Innovations in palm oil processing waste-to-energy solutions enable mills to convert solid waste byproducts such as palm kernel shells and fibers into usable energy. This not only reduces pollution but also creates renewable energy for the palm oil mill.

4. Using advanced palm oil refining technologies:

New refining methods, including supercritical fluid extraction and membrane technology, offer superior separation capabilities. They help remove undesirable components while retaining beneficial ones, resulting in higher quality refined palm oil.

5. Performing palm oil fractionation:

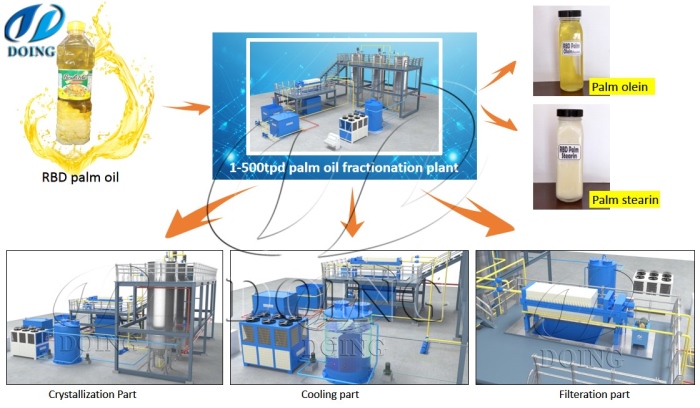

Advanced fractionation technology can separate palm oil into different fractions, each with a different melting point and fatty acid composition. This enables producers to tailor products to specific market needs, such as the oleochemical or nutraceutical industries.

Palm oil fractionation machine

Palm oil fractionation machine

In short, the palm oil processing industry is experiencing a dynamic era of progress, characterized by technological innovations aimed at improving the sustainability, productivity and product quality of palm oil processing. Through these innovations, the palm oil processing industry aims to continue to provide a major global commodity while addressing environmental challenges and meeting consumer expectations for healthier and more ethical products. In addition, if you have other questions about the palm oil processing industry, please feel free to consult us! We also have a local branch in Nigeria, and if you want to set up a palm oil mill in Nigeria, we can provide you with the most powerful guidance!

PREV:What are the palm oil making machines and what are their prices in Ivory Coast?

PREV:What are the palm oil making machines and what are their prices in Ivory Coast?

NEXT:What are the best configurations and strategies to improve the efficiency of palm oil refining?

NEXT:What are the best configurations and strategies to improve the efficiency of palm oil refining?

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines