How to establish a 10-20 t/d palm kernel oil extraction factory in Lagos, Nigeria?

Nigeria, as the largest producer of palm oil in Africa, offers great potential for entrepreneurs who are interested in starting a business in the edible oil sector. Lagos, as the country’s economic hub, has abundant market, infrastructure and raw material resources. Establishing a 10-20t/d palm kernel oil extraction factory in Lagos, Nigeria, requires careful planning, the right palm kernel oil extraction equipment and a clear understanding of the palm kernel oil extraction process. Here is a step-by-step guide on how to establish a 10-20t/d palm kernel oil extraction factory in Lagos, Nigeria.

Step1. Layout and Planning of 10-20T/D Palm Kernel Oil Extraction Factory

The first step is to design a functional layout for the 10-20t/d palm kernel oil extraction factory. A typical palm kernel oil extraction factory includes a palm kernel processing and pressing workshop, storage areas for raw materials and finished products, offices and laboratories. The technical team can provide detailed 10-20t/d palm kernel oil extraction factory layouts, palm kernel oil extraction equipment diagrams and foundation plans tailored to the available site conditions in Lagos. Proper planning ensures smooth workflow and maximizes efficiency.

10-20T/D palm kernel oil extraction factory

10-20T/D palm kernel oil extraction factory

Step2. Preparation of Raw Materials

The second step is to prepare the raw materials. The main raw material for a 10-20t/d palm kernel oil extraction factory is palm kernel, which can come from your own palm oil extraction factory or be purchased separately from outside. In addition, you can also sign long-term agreements with plantations, cooperatives or middlemen to ensure a stable supply chain of raw materials. It is worth mentioning that these palm kernels usually contain fibers and impurities, which need to be cleaned before preparing for palm kernel oil extraction.

Palm kernels

Palm kernels

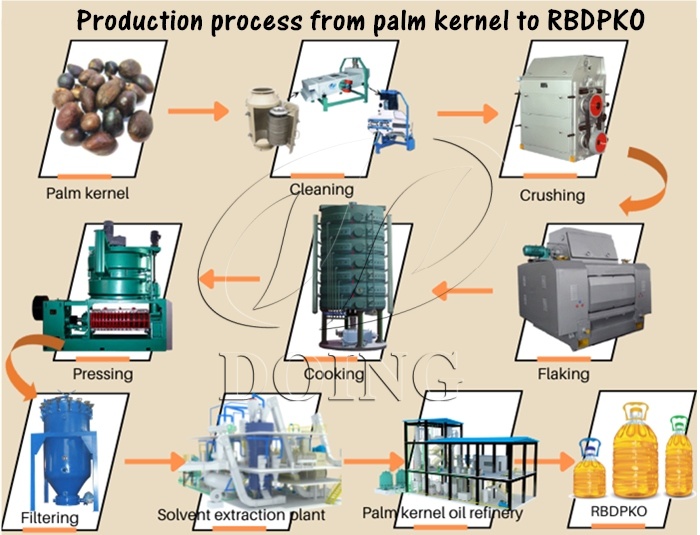

Step3. Understanding of Palm Kernel Oil Extraction Process

The third step is to understand the overall palm kernel oil extraction process. The typical palm kernel oil extraction process includes:

1. Raw material cleaning: Clean and dry the palm kernel to remove the fiber impurities on the surface of the palm kernel.

2. Palm kernel shell crushing and separation: Crush the palm kernel to separate the kernel from the shell. .

3. Crushing: Crush the palm kernel into smaller particles for efficient pressing.

4. Cooking: Adjust the moisture and temperature of the palm kernel to the optimal pressing level.

5. Pressing: Use a palm kernel oil press equipment to extract crude palm kernel oil. Temperature control is key to avoid spoilage.

6. Refining: Remove impurities through filtration, degumming, deacidification, decolorization and deodorization processes.

7. Packaging: Store refined palm kernel oil in bulk tanks or containers that can be directly used by consumers.

Overall palm kernel oil extraction process

Overall palm kernel oil extraction process

Step4. Purchase of Palm Kernel Oil Extraction Equipment

The fourth step is to purchase the required palm kernel oil extraction equipment. For a 10-20 t/d palm kernel oil extraction factory, it is necessary to purchase efficient and scalable mechanical palm kernel oil extraction equipment such as bucket elevators, fiber separators, palm kernel shell crushing and separation equipment, crushers, woks, palm kernel oil press equipment, filters, palm kernel oil refining equipment and packaging equipment. Among them, the palm kernel oil press equipment, which mainly plays a role in palm kernel oil extraction, is a durable single screw palm kernel oil press equipment made of 45-grade forged steel. Its short bipolar pressing process prevents overheating and clogging, ensuring efficient oil pressing with a residual oil rate of 6-7%. The palm kernel oil press equipment has an output of 500 kg/hour and is driven by a stable four-stage motor.

Palm kernel oil extraction equipment

Palm kernel oil extraction equipment

Step5. Final Considerations

In order to establish a 10-20 t/d palm kernel oil extraction factory in Lagos, Nigeria, the palm kernel oil extraction factory also needs several key equipment (such as crushers and oil pressers) to operate simultaneously. Therefore, regular maintenance of palm kernel oil extraction equipment and professional training of operators are essential to ensure smooth palm kernel oil extraction. For this, I recommend you to cooperate with Henan Glory Company, who can provide you with free palm kernel oil extraction equipment installation and operation training as well as equipment maintenance services.

In short, Lagos has advantages such as abundant raw materials and a booming palm kernel oil market, making it an ideal location for establishing a 10-20 t/d palm kernel oil extraction factory. By following the above steps, you can establish a successful palm kernel oil extraction factory in Lagos, Nigeria, meet local needs and contribute to the economic growth of the region. If you have any other questions or needs, please consult Henan Glory Company now!

PREV:How much it will cost to make and install 20TPD palm oil processing plant in Nigeria?

PREV:How much it will cost to make and install 20TPD palm oil processing plant in Nigeria?

NEXT:Automated Small Palm Oil Production Line: Africa's Efficiency-Boosting Solution!

NEXT:Automated Small Palm Oil Production Line: Africa's Efficiency-Boosting Solution!

Leave A Message

If you want to know more information about How to establish a 10-20 t/d palm kernel oil extraction factory in Lagos, Nigeria? . pls kindly leave your phone number, We will back to you ASAP once we got your message.

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

Palm Kernel Cracker and Crusher Hot Sale in Nigeria: You Can Pick Them Up in Our DOING Nigeria Local Branch

-

What Are the Types of Fractionated Palm Oil? What Are They Used for?

What Are the Types of Fractionated Palm Oil? What Are They Used for?

-

What Is the Clarification Station in a Large Palm Oil Mill?

What Is the Clarification Station in a Large Palm Oil Mill?

-

FAQs About Palm Kernel Oil Extraction Machines

FAQs About Palm Kernel Oil Extraction Machines