Palm kernel oil press production line

Palm kernel oil press production line introduction:

Pam kernel oil press is different from palm fruit oil press processing line. Traditional palm oil includes crude palm oil (CPO) pressed from palm fruit, and refined palm oil (RPO), not includes palm kernel oil.

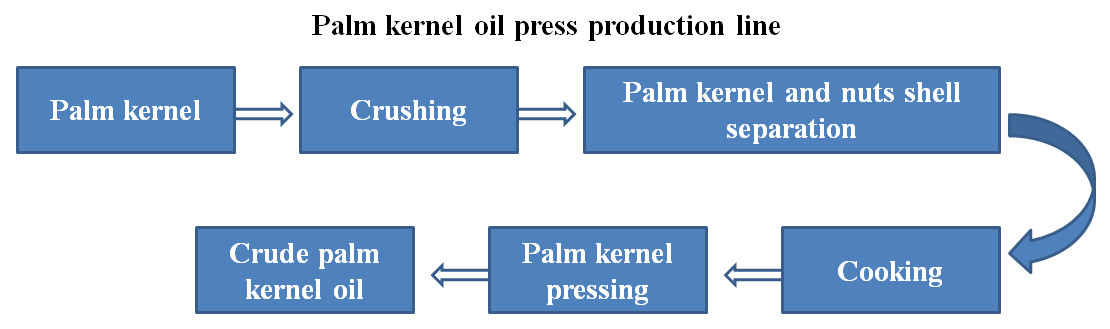

Work flow of palm kernel oil press production line:

Main process of palm kernel oil press production line:

(1)Palm kernel Cleaning : It is used for removing the iron impurities, stone, fiber and others. These impurities are bad for machines, especial for the palm kernel expeller.

(2)Palm kernel crushing: Because the palm kernel is hard and big size, it is required to crash to smaller and even pieces.

(3)Palm kernel and nuts shell separation. Both dry and wet separations are available. Wet separation is mostly used in palm kernel separation, on basis of difference of relative density of palm kernel and shell.

(4)Palm kernel drying. Fresh kernel contains 20% moisture. Palm kernel has no mildew during transportation and storage while moisture drops below 7%.

(5)Cooking section: It is used for heating and cooking the crashing materials, to make is suitable for pressing, doing like this can help final user get the maximum oil and good quality cakes.

(6)Palm kernel oil pressing. Palm kernel oil pressing production line is simple with usual oilseeds. The pre-pressing by oil pressing machine can obtain 1/4 palm kernel oil, and residual oil need twice pressing.

(7)Palm kernel Filtering section: after pressing, there are some oil dregs in the crude oil, after clarifying, we need to filter the crude oil to avoid to jam the oil pipes during refining processes.