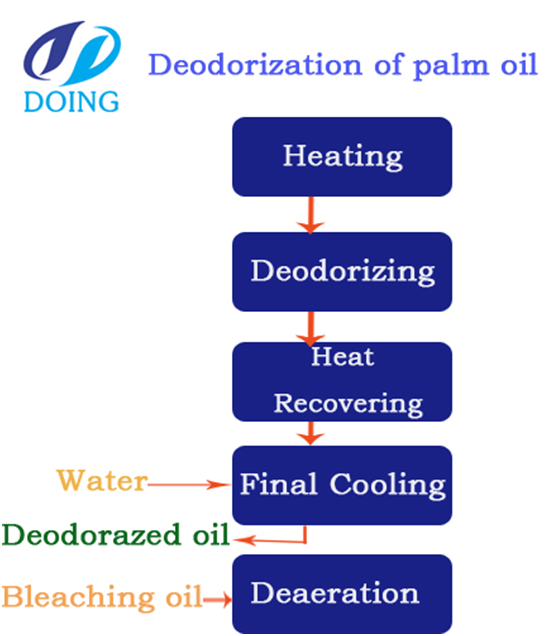

Deodorization technology of palm oil

Palm oil deodorization

Palm oil contains various components, each with its specific volatility. In physical refining, it is mainly free fatty acids (FFA) that need to be stripped. Apart from FFA, other volatile components, either valuable (tocopherols, sterols, etc) or unwanted (off-flavors, pesticide residues, light polycyclic aromatic hydrocarbons, dioxins, etc), are also removed during deodorization.

| Deodorized palm oil | |

| Quality parameter | Physical refining palm oil |

| FFA (%) | 85-90 |

| Tocopherols (%) | 0.15-0.30 |

| Sterols (%) | 0.2-0.4 |

| Squalene (%) | 0.5-1.0 |

| Neutral oil (%) | 6-9 |

| Distillate flow (%) | 0.3-1.0 |

Leave A Message

If you want to know more information about Deodorization technology of palm oil . pls kindly leave your phone number, We will back to you ASAP once we got your message.

-

Successful order for 1tph palm oil processing equipment from a customer in Nigeria

-

Guinea client orders 1TPD electric heating palm oil refinery plant from Henan Glory

-

Henan Glory lands Guatemalan order for small scale palm oil processing equipment

-

Henan Glory supplies palm oil processing equipment to its overseas warehouse in Nigeria

-

A repeat Indonesian customer chose Henan Glory for palm oil press machine spare parts order

-

Nigerian client orders a 2tph drum-type palm fruit thresher from Henan Doing Nig. Co.,Ltd

-

200kg/d mini palm oil refining plant: Henan Glory’s new deal in Central Africa

-

-

Shipment Notice: 1tph compact palm oil processing line successfully dispatched to Nigeria

-

Cooperation with Indonesia: Henan Glory to supply 500kg/h palm oil pressing machine

-

2tph Palm Oil and Palm Kernel Oil Processing Machines Project in Nigeria

-

-

-

1tph palm oil pressing machines successfully installed in Lagos, Nigeria

-

-

-

-

500kg/h palm oil and palm kernel oil processing plant project in Ghana

-

-

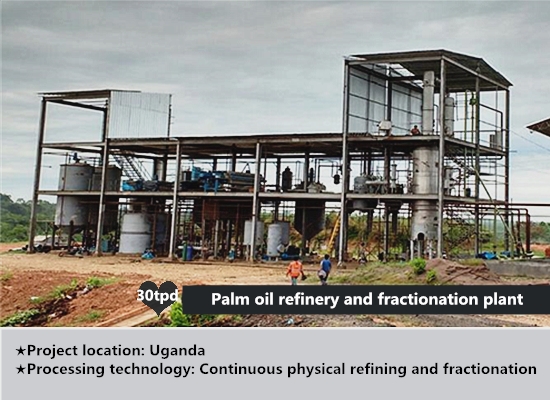

30tpd palm oil refinery and fractionation plant project successfully installed in Uganda